Air-tight bottom support stirring device of efficient anaerobic fermentation tank

A technology of anaerobic fermentation tank and stirring device, which is applied in the directions of mixer accessories, transportation and packaging, mixers, etc., can solve the problems of uncommon application of bottom support, inoperable stirring system, easy failure of mechanical seals, etc., and achieves maintenance-free later period. , The effect of improving the service life and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

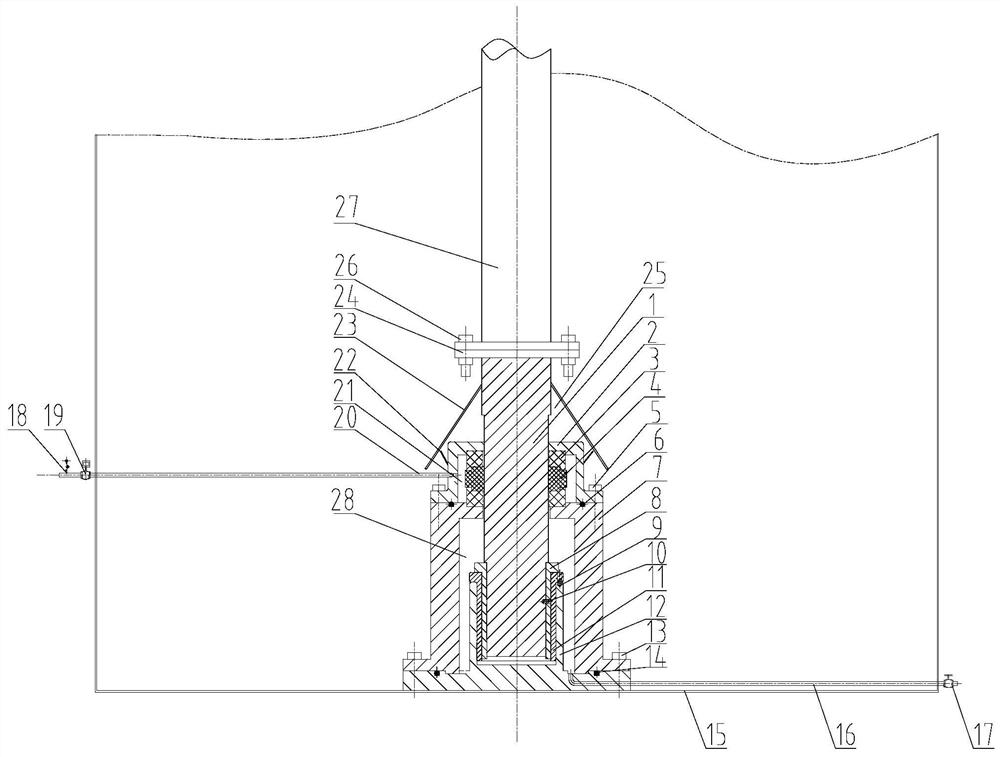

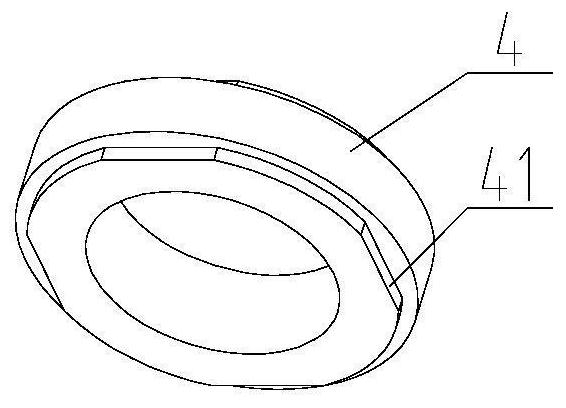

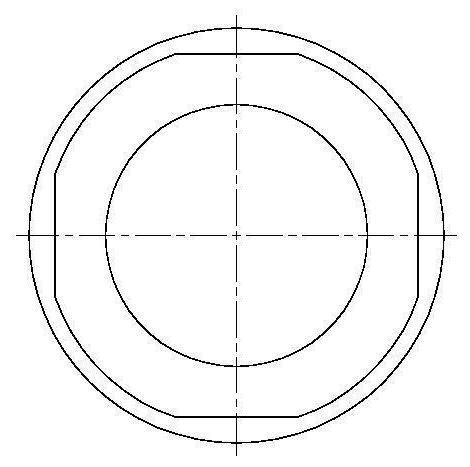

[0033] Embodiment 1: A high-efficiency anaerobic fermentation tank air-tight bottom support stirring device of the present invention includes a stirring shaft I1 placed in a tank body 15, a bearing seat 12, a bottom bearing 11, a shaft sleeve 8, a sleeve 7, and a top Gland 2, pneumatic sealing device, the bearing seat 12 is placed at the bottom of the tank body 15, the inner ring of the bearing seat 12 is provided with a bottom bearing 11, and the bottom bearing 11 is provided with a shaft sleeve 8 and a sleeve 8 installed at one end of the stirring shaft I1 Set on the stirring shaft I1, one end is connected with the outer ring of the bearing seat 12, and the other end is connected with the top gland 2 set on the stirring shaft I1 through the fastening bolt I5, between the sleeve 7 and the inner ring of the bearing seat 12 A settling chamber 28 is formed, an air chamber 21 is formed between the sleeve 8 and the top gland 2, and a pneumatic sealing device is installed on the sti...

Embodiment 2

[0044] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the minimum gap between the deflector 22 and the fender 23 in this embodiment is 2 mm. The rising biogas bubbles carrying the fine sand hit the fender 23 and the baffle plate 22, the biogas bubbles burst, and the fine sand settles. The baffle plate 22 and the fender 23 work together to prevent fine sand particles from entering the dynamic sealing ring 4 from the gap of the static sealing ring 3, causing damage to the dynamic sealing ring 4 and affecting the sealing effect.

Embodiment 3

[0045] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the minimum gap between the deflector 22 and the fender 23 in this embodiment is 4 mm. The rising biogas bubbles carrying the fine sand hit the fender 23 and the baffle plate 22, the biogas bubbles burst, and the fine sand settles. The baffle plate 22 and the fender 23 work together to prevent fine sand particles from entering the dynamic sealing ring 4 from the gap of the static sealing ring 3, causing damage to the dynamic sealing ring 4 and affecting the sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com