A kind of polyurethane flame retardant film, preparation method and application thereof

A flame retardant film, polyurethane technology, used in transportation and packaging, removable outer jackets, vehicle parts, etc., can solve problems such as loss of flame retardant effect, and achieve the effect of avoiding migration, narrowing gaps, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

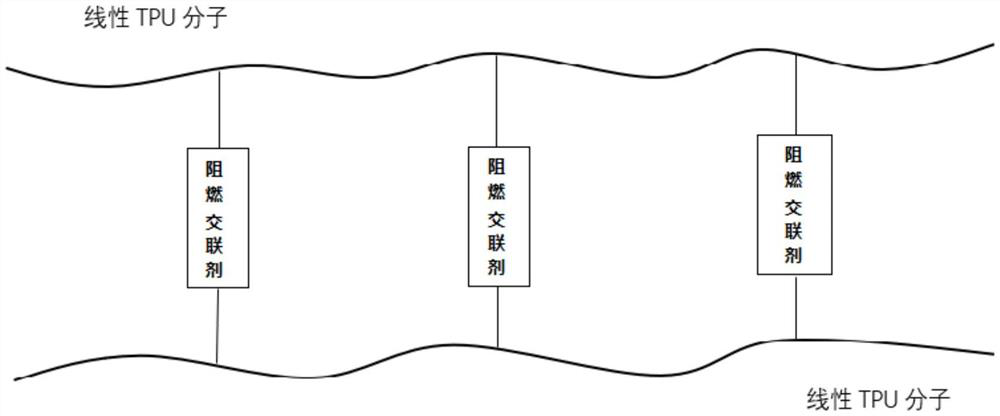

Method used

Image

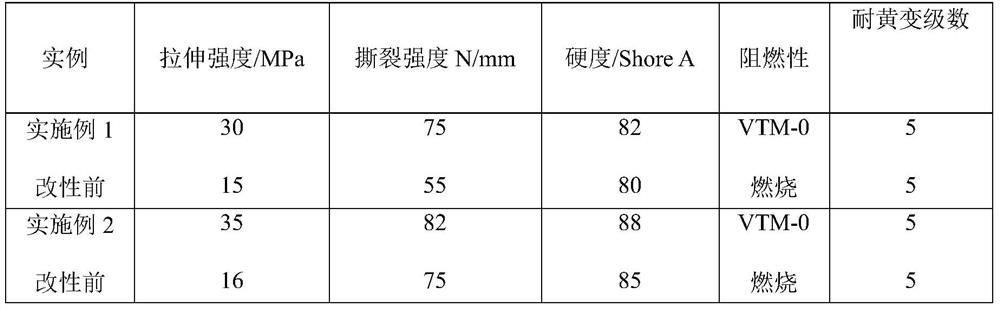

Examples

Embodiment 1

[0041] A kind of polyurethane flame retardant film, comprises the raw material of following weight part:

[0042] Aliphatic TPU particles: 86.6 parts by weight, hardness 80Shore A

[0043] Flame retardant crosslinking agent: 12 parts by weight

[0044] Antioxidant: composite antioxidant B215, 0.6 parts by weight

[0045] Ultraviolet absorber: UV-196, 0.8 parts by weight

[0046] The preparation method of above-mentioned polyurethane flame retardant film comprises the following steps:

[0047] 1) Preparation of flame retardant crosslinking agent:

[0048] Heat 35.3g of phosphate diols (hydroxyl value 440mgKOH / g) in the reactor to 100°C, remove water under reduced pressure for 2 hours, then feed nitrogen into the reactor, and cool down to 50°C under normal pressure, Add 64.7g of dicyclohexylmethane diisocyanate, control the prepolymerization temperature to 90°C, and react for 2.5 hours to prepare a polyurethane prepolymer with an -NCO content of 10% by weight, that is, a fla...

Embodiment 2

[0054] A kind of polyurethane flame retardant film, comprises the raw material of following weight part:

[0055] Aliphatic TPU particles: 84 parts by weight, hardness 85Shore A

[0056] Flame retardant crosslinking agent: 15 parts by weight

[0057] Antioxidant: composite antioxidant B225, 0.5 parts by weight

[0058] Ultraviolet absorber: UV-1164, 0.5 parts by weight

[0059] The preparation method of above-mentioned polyurethane flame retardant film comprises the following steps:

[0060] 1) Preparation of flame retardant crosslinking agent:

[0061] Heat 35.3g of phosphate diols (hydroxyl value 480mgKOH / g) in the reactor to 110°C, remove water under reduced pressure for 2 hours, then feed nitrogen into the reactor, and cool down to 55°C under normal pressure, Add 75g of dicyclohexylmethane diisocyanate, control the prepolymerization temperature to 80°C, and react for 2.5 hours to prepare a polyurethane prepolymer with an -NCO content of 16% by weight, that is, a flame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com