Surface treatment device for textile fabrics

A technology of surface treatment device and exhaust gas treatment device, which is applied in the direction of ultrasonic/sonic fiber treatment, dispersed particle separation, chemical instruments and methods, etc., and can solve the problems of inconsistent spacing of textile discharge tubes, inconsistent treatment of textiles, poor consistency of textiles, etc. problems, to achieve the effect of ensuring color fastness, avoiding excessive temperature, and avoiding temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

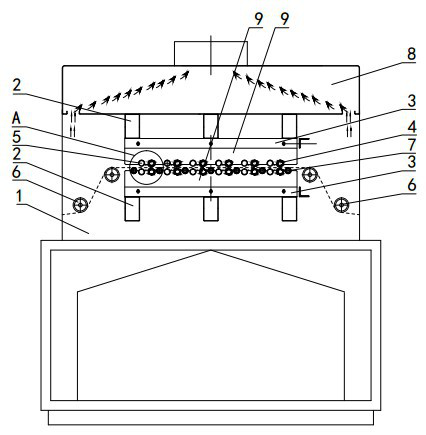

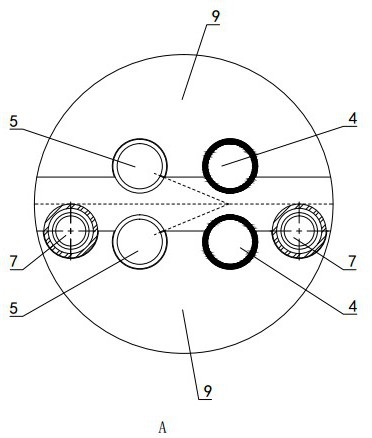

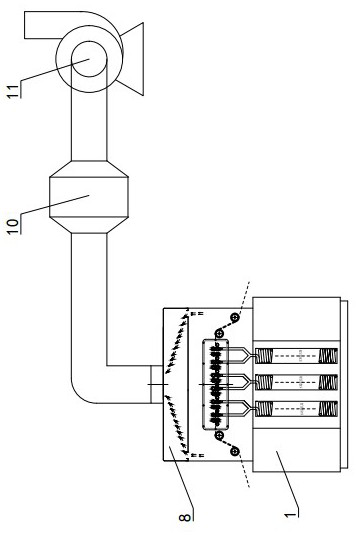

[0035] Figure 1~11 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~11 The present invention will be further described.

[0036] A textile surface treatment device, including a discharge tube 4, an air guide tube 5, a positioning shaft 7 and a waste gas treatment device, the discharge tubes 4 are arranged in pairs, and the paired two discharge tubes 4 are arranged in parallel and at intervals, and each discharge tube 4 The input side of the textile fabrics is provided with an air guide tube 5, and the side of the air guide tube 5 close to the corresponding discharge tube 4 is provided with an air injection port 501, and the paired two discharge tubes 4 are connected to the power supply, and the waste gas treatment device is arranged in the discharge tube 4. On the upper side of the tube 4, the positioning shaft 7 is provided with a positioning part parallel to the discharge tube 4, the positioning part is located in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com