Dyeing and washing one bath process for pretreatment of polyester-cotton fabric

A polyester-cotton and polyester technology, applied in the field of fiber preparation, can solve problems affecting fiber performance and appearance quality, large sewage discharge, complex and cumbersome process, etc., to improve equipment utilization and worker production efficiency, and save water and electricity consumption , the effect of shortening the dyeing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

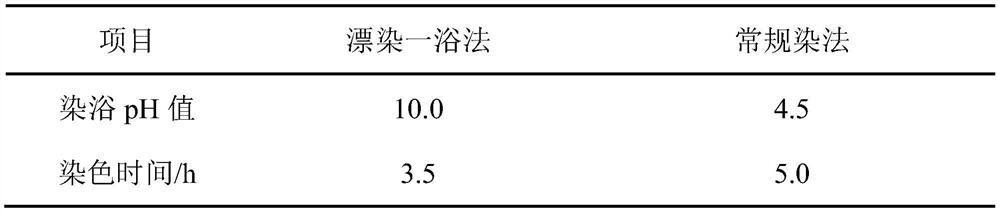

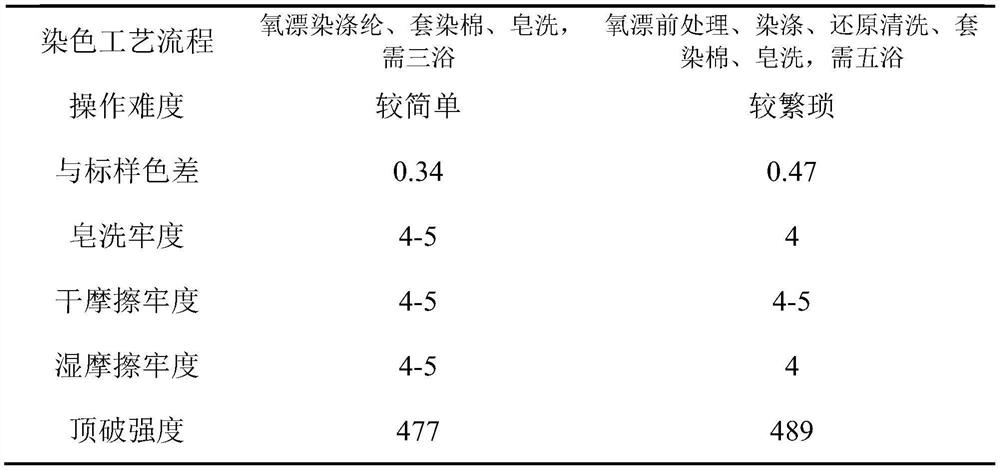

[0032] The dyeing equipment adopted in the present embodiment is a high-temperature and high-pressure liquid flow dyeing machine, an Italian MCS dye vat, model MF-2XJHT, and the method of dyeing and washing one bath of polyester-cotton pretreatment comprises the following steps:

[0033] Bath dyeing of polyester: Add hydrogen peroxide, alkaline leveling agent HK-2030, and Longsheng alkaline disperse dye ALK(N) series to the first mixture composed of polyester fabric and water with a mass ratio of 1:10, in the bath The ratio is 1:10, the bath dyeing pH range is 10, and the bath dyeing temperature range is 130°C, dyeing is carried out for 4060 minutes to obtain bath dyed polyester, wherein the hydrogen peroxide and the alkaline leveling agent HK- 2030. The concentrations of the ALK(N) series of Longsheng basic disperse dyes are 5g / L, 2g / L, and 2g / L respectively.

[0034] Cotton over-dyeing: Add reactive dyes, sodium sulfate, and sodium carbonate to the second mixture consisting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com