Shifting fork gear shifting method, gearbox, new energy vehicle power assembly and vehicle

A technology of shifting fork and gearbox, applied in the direction of transmission, gear transmission, transmission control, etc., can solve the problems of high noise and large shifting shock, achieve small shifting shock and reduce shifting shock , The effect of reducing the hidden danger of early damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, a shift fork shift control method, used in a two-speed transmission system for shift fork shift, controls the movement of the shift fork shift mechanism through a power output signal, and realizes automatic switching between two gears; The shifting fork shifting mechanism is driven by a three-position cylinder; the power output signal is composed of a torque signal and a speed signal; the gear shift is completed in the following order; when one signal appears, wait for the other signal; When it occurs, the three-position cylinder first drives the shift fork to move to perform gear removal, and uses the middle position of the three-position cylinder to stop the shift fork or reduce the moving speed of the shift fork to form a shift buffer.

[0032] Wherein, the fork shifting mechanism also utilizes electromagnetic force to assist in gearing.

Embodiment 2

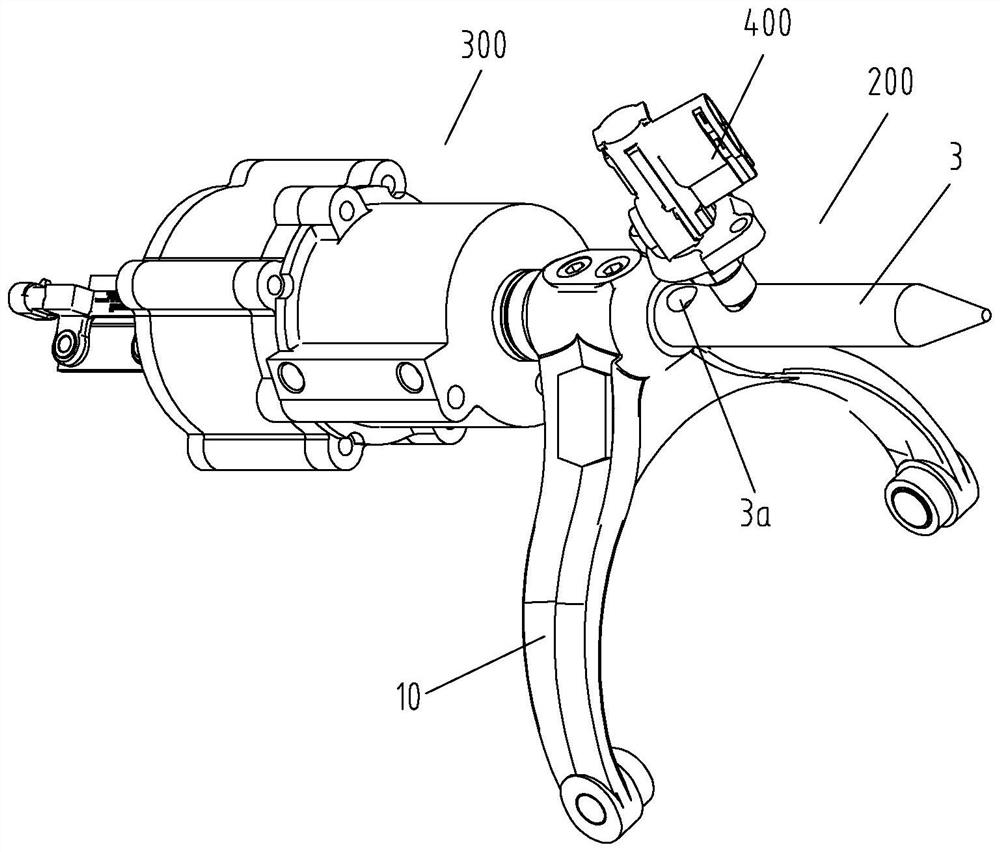

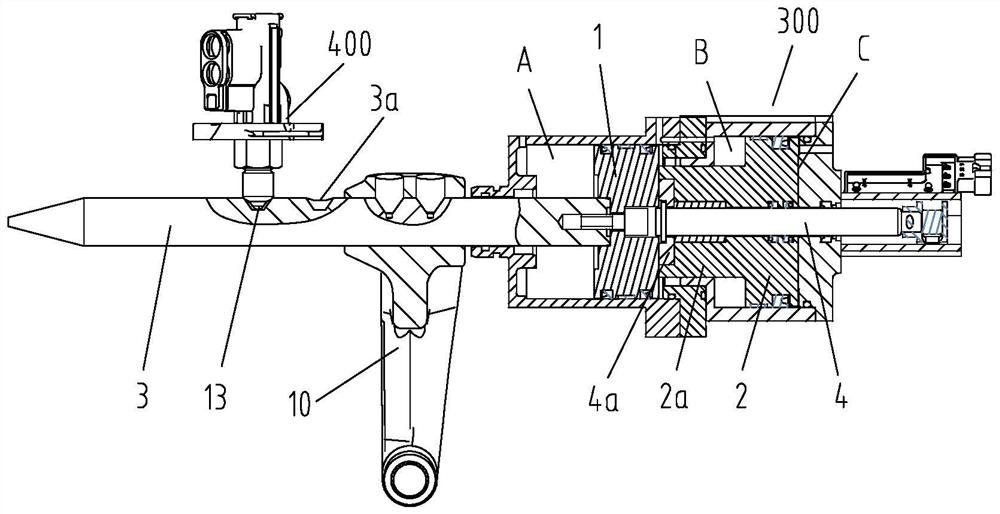

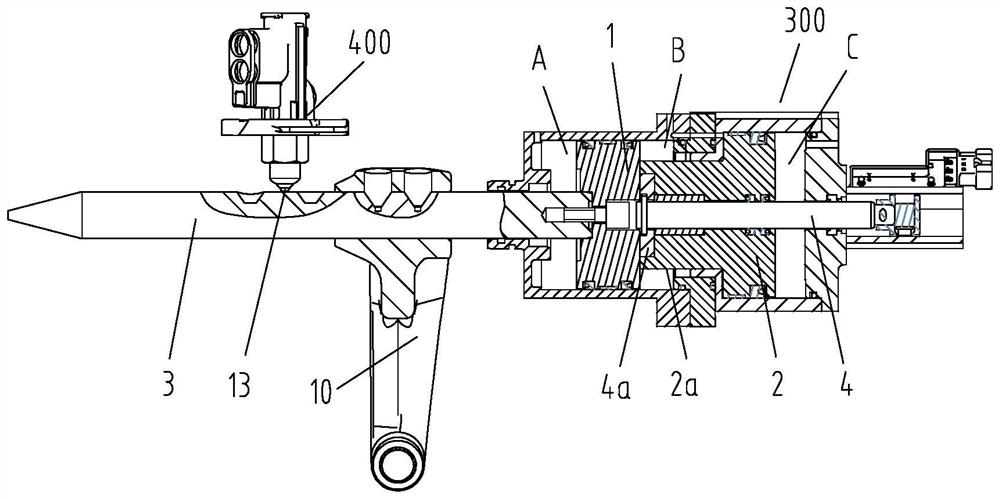

[0033] Example 2, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , a two-speed planetary automatic transmission, including a single-stage planetary transmission 100 and a shift fork shift mechanism 200, the shift fork shift mechanism 200 is connected with a shift drive cylinder 300; the shift drive cylinder 300 is composed of a three-position cylinder , the two limit positions of the three-position cylinder correspond to the two gear positions of the gearbox respectively, and the middle position between the two limit positions is used to form a shift buffer between the gear removal and the gear engagement.

[0034] Wherein, the three-position cylinder includes a first piston 1 and a second piston 2, the first piston 1 is located in the first piston cavity and is coaxially fixedly connected with one end of the shift fork rod 3 of the shift fork shift mechanism, and the shift fork rod 3 constituting the first piston rod; the second pist...

Embodiment 3

[0045] Example 3, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , and combined with Figure 7 , a powertrain including an AC asynchronous motor 14 and a gearbox; the gearbox is composed of the two-speed planetary automatic gearbox of Embodiment 2; wherein, the sun gear is integrally formed or fixedly connected to the AC asynchronous motor 14 motor shaft 14a.

[0046]Wherein, the AC asynchronous motor 14 has a double-cooling structure, and its rotor body is made of cast copper, wherein, the cooling method is a combination of water cooling and oil cooling, and the water cooling adopts the external circulation cooling water method to cool the motor housing 14b, The oil cooling uses insulating oil 15 as a heat transfer medium to perform heat conduction cooling on the rotor 14c and the stator 14d inside the motor. The insulating oil is filled in the inner cavity of the rotor and stator of the motor, and the oil level is lower than the axis line of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com