A kind of conformal preparation method and product of thick film heat flow meter

A heat flow meter and thick film technology, which is applied in the field of conformal preparation of thick film heat flow meters, can solve the problems that thin film sensors are not as reliable as thick film sensors, cannot achieve accurate measurement of heat flow on the surface of heat sources, and lack surface conformal sensor preparation technology. , to achieve the effect of no mask, good economic adaptability, and increased thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

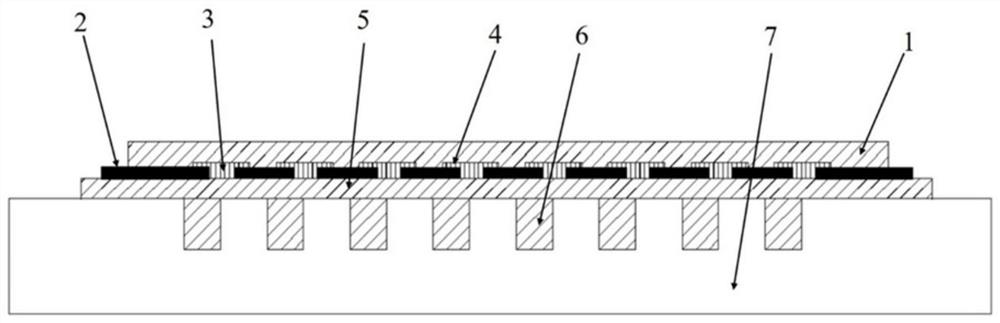

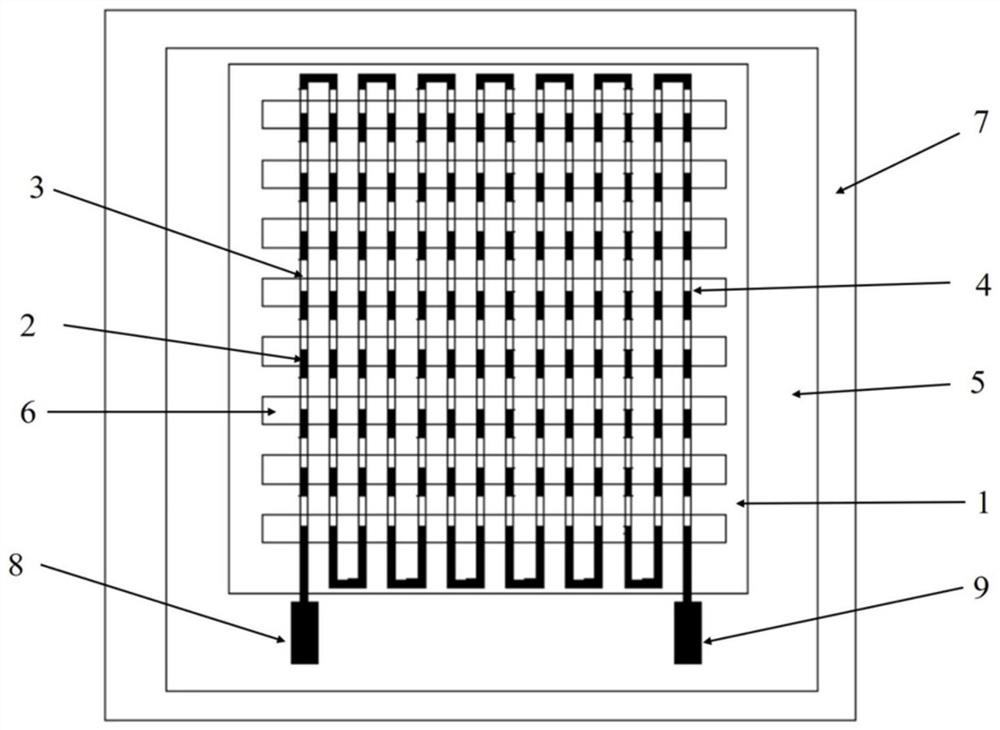

[0031] The application of the present invention provides a method for preparing a heat flow meter and the prepared thick film heat flow meter, wherein the preparation method is as follows:

[0032] Step 1: use nanosecond pulse laser etching to form grooves with the same shape as the thermal resistance layer 6 on the substrate 7, then clean and dry with deionized water.

[0033] The second step: use a micro-pen to directly write the polyamic acid solution, and heat-cure to form a polyimide layer to fill the grooves formed by laser etching in the previous step to form a thermal resistance layer 6 . The thermal resistance layer fills the entire groove and is embedded in the upper surface of the substrate, and the thermal resistance layer is flush with the upper surface of the substrate.

[0034] Step 3: Prepare the insulating layer 5 on the substrate 7 and the thermal resistance layer 6 by directly writing the polyamic acid solution with a micro-pen, and thermally curing to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com