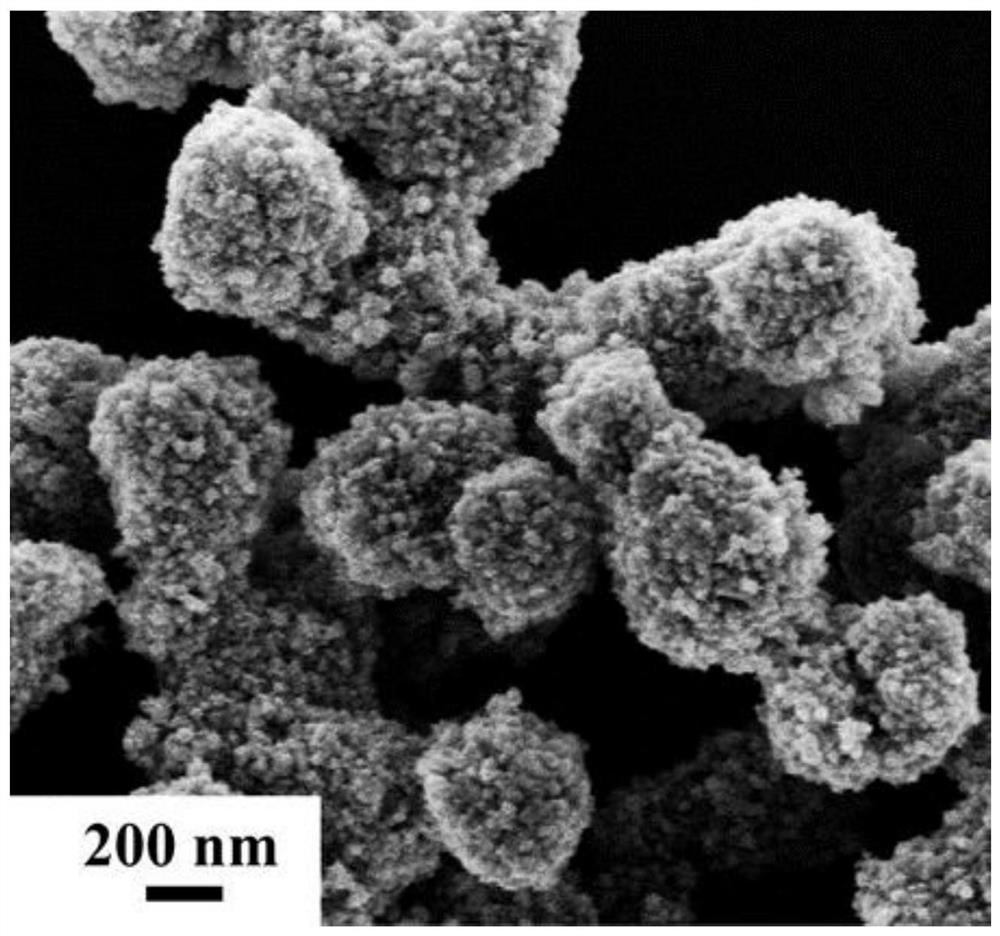

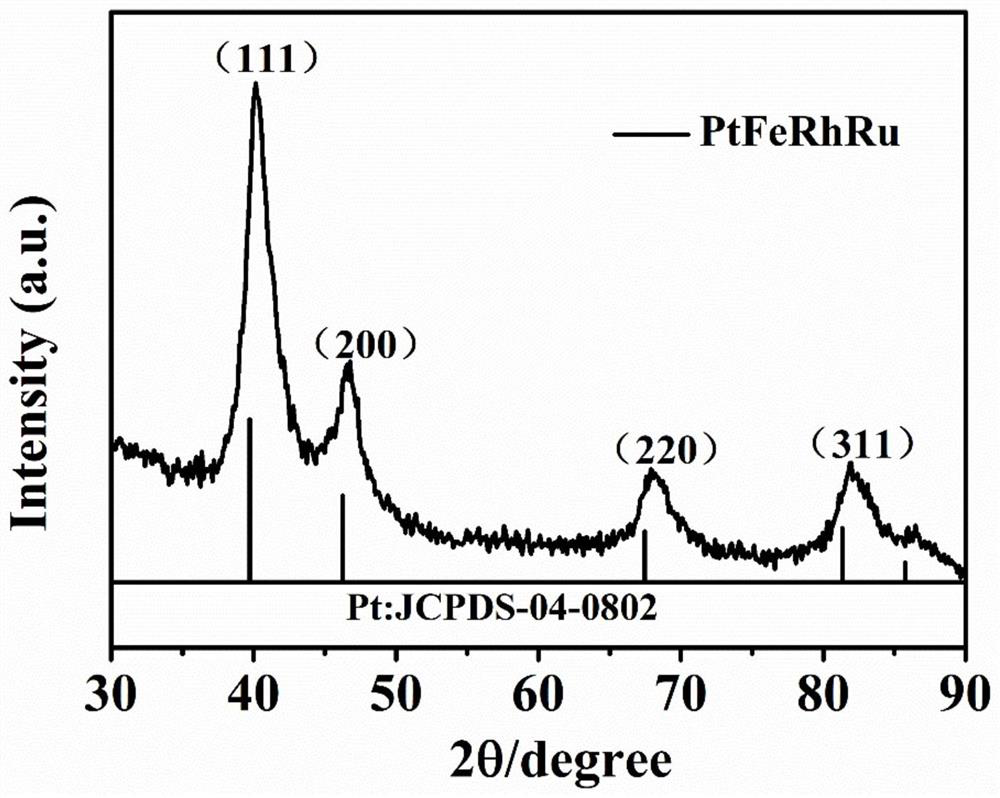

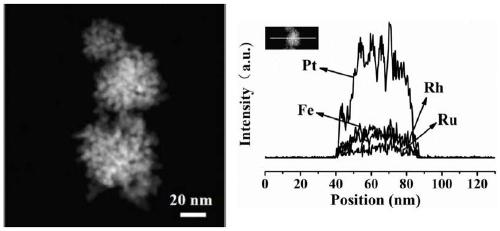

Synthesis and application of quaternary platinum-iron-rhodium-ruthenium nano-alloy with hierarchical structure

A hierarchical structure and nano-alloy technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, to achieve the effect of novel crystal structure, good stability and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The synthesis and application of the quaternary platinum-iron-rhodium-ruthenium nano-alloy of hierarchical structure comprises the following steps:

[0020] (1) Add 36.4 mg of cetyltrimethylammonium bromide (CTAB) as a surfactant, and four metal salts of chloroplatinic acid, iron acetylacetonate, rhodium chloride, and ruthenium chloride into the organic solvent octylamine , the amount of metal used is 0.043 mmol, the ratio of platinum salt, iron salt, rhodium salt, and ruthenium salt metal precursor is 25:8:5:5, the volume of octylamine added is 6.2 mL, stirred at room temperature for 10 minutes, and ultrasonicated for 10 minutes , until the metal salt is completely dissolved;

[0021] (2) Add ascorbic acid to the mixed solution obtained in step (1) in an amount of 18 mg, and stir at room temperature for 10 minutes;

[0022] (3) Transfer the mixed solution obtained in step (2) to an autoclave for reaction for 8 hours, with the temperature controlled at 190°C;

[0023]...

Embodiment 2

[0025] (1) Add 36.4 mg of cetyltrimethylammonium bromide (CTAB) as a surfactant, and four metal salts of chloroplatinic acid, iron acetylacetonate, rhodium chloride, and ruthenium chloride into the organic solvent octylamine , the amount of metal used is 0.043 mmol, the ratio of platinum salt, iron salt, rhodium salt, and ruthenium salt metal precursor is 25:8:7:3, the volume of octylamine added is 6.2 mL, stirred at room temperature for 10 minutes, and ultrasonicated for 10 minutes , until the metal salt is completely dissolved;

[0026] (2) Add ascorbic acid to the mixed solution obtained in step (1) in an amount of 18 mg, and stir at room temperature for 10 minutes;

[0027] (3) Transfer the mixed solution obtained in step (2) to an autoclave for reaction for 8 hours, with the temperature controlled at 190°C;

[0028] (4) The product obtained in step (3) is cooled, washed, and centrifuged to obtain a quaternary platinum-iron-rhodium-ruthenium nano-alloy, and the sample is ...

Embodiment 3

[0030] (1) Add 36.4 mg of cetyltrimethylammonium bromide (CTAB) as a surfactant, and four metal salts of chloroplatinic acid, iron acetylacetonate, rhodium chloride, and ruthenium chloride into the organic solvent octylamine , the amount of metal used is 0.043 mmol, the ratio of platinum salt, iron salt, rhodium salt, and ruthenium salt metal precursor is 25:8:3:7, the volume of octylamine added is 6.2 mL, stirred at room temperature for 10 minutes, and ultrasonicated for 10 minutes , until the metal salt is completely dissolved;

[0031] (2) Add ascorbic acid to the mixed solution obtained in step (1) in an amount of 18 mg, and stir at room temperature for 10 minutes;

[0032] (3) Transfer the mixed solution obtained in step (2) to an autoclave for reaction for 8 hours, with the temperature controlled at 190°C;

[0033] (4) The product obtained in step (3) is cooled, washed, and centrifuged to obtain a quaternary platinum-iron-rhodium-ruthenium nano-alloy, and the sample is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com