Battery dispensing curing production line and process

A battery and production line technology, applied in the direction of lead-acid battery, lead-acid battery construction, assembling battery machine, etc., can solve the problems of low energy utilization rate, short transmission and curing stroke, inability to directional heating, etc., to improve the directional utilization rate of heat, Short curing time, adjustable heat intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

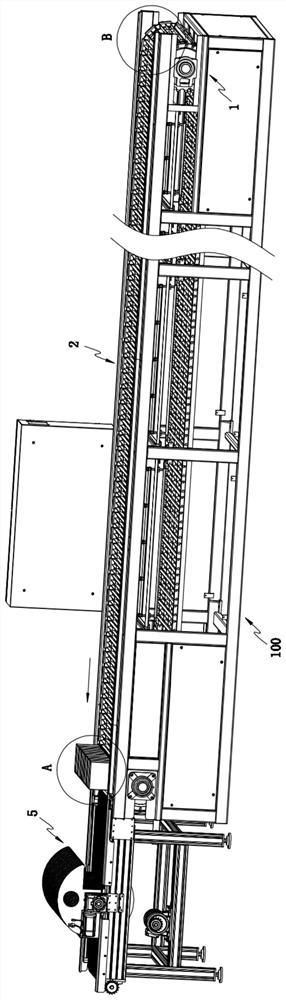

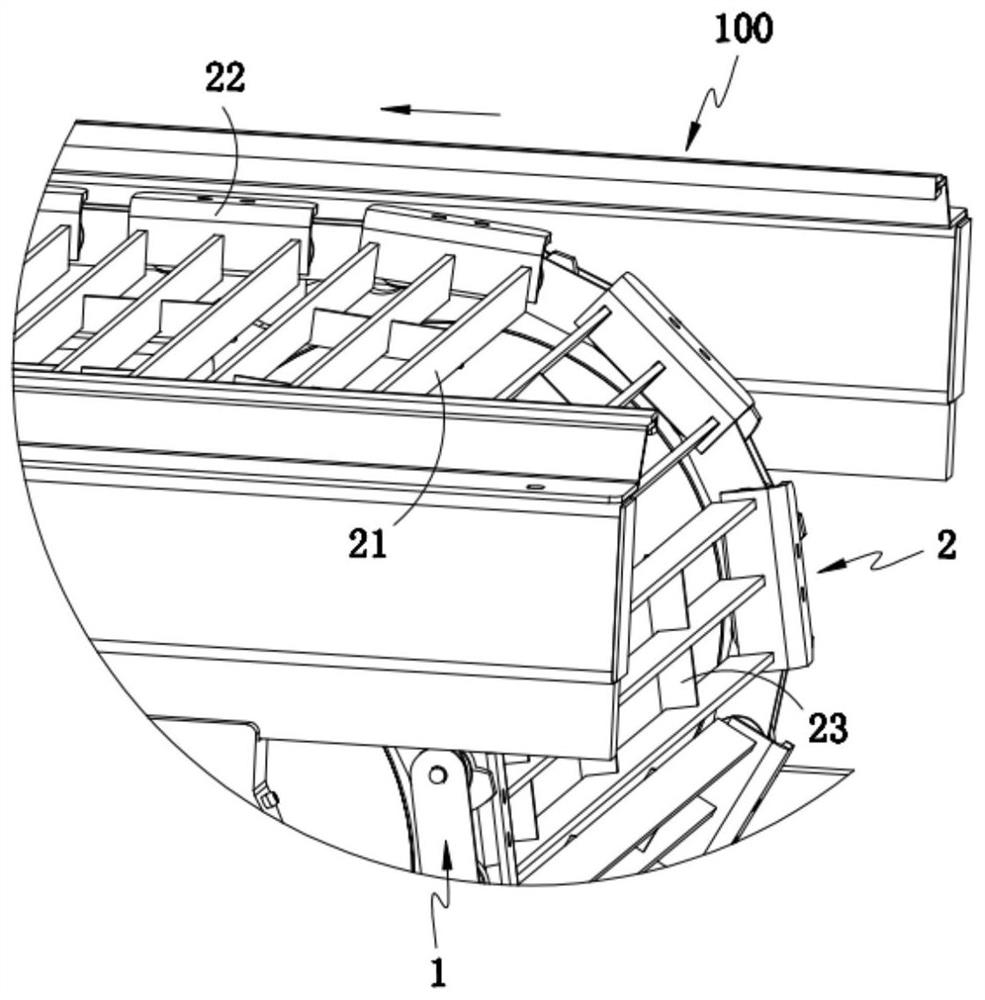

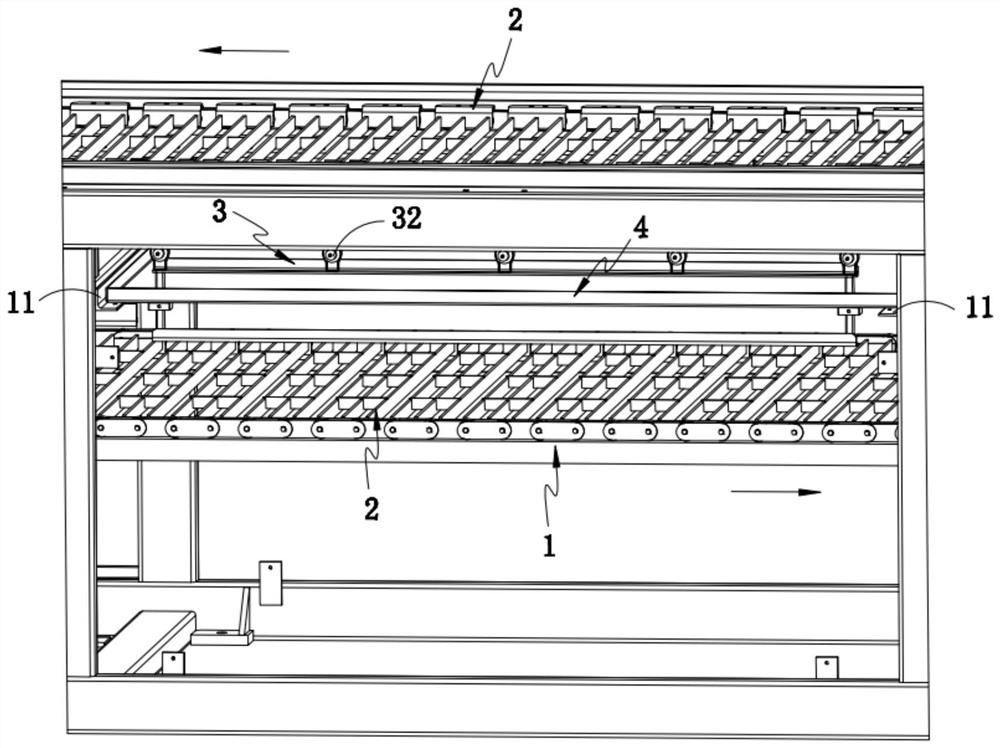

[0041] Such as Figure 1-3As shown, the battery dispensing and curing production line includes a frame 100 and a rotary conveying mechanism 1 installed on the frame 100, and also includes a hollow chain plate mechanism 2 evenly distributed on the rotary conveying mechanism 1, and is arranged on The radiation heating mechanism 3 and the heat reflection mechanism 4 in the middle space of the rotary conveying mechanism 1, such as Figure 4-5 As shown, the battery packs 10 that are glued and arranged one by one are stuck upside down on the hollow chain plate mechanism 2. During the transmission process, the heat radiated outward by the radiation heating mechanism 3 is reflected upward by the heat reflection mechanism 4. And through the hollow chain plate mechanism 2, the dispensing on the cover of the battery pack 10 is heated intensively.

[0042] In this implementation, by setting the hollow chain plate mechanism 2 to limit the transmission of the battery packs 10 that are arra...

Embodiment 2

[0055] For the sake of brevity, only the difference between Embodiment 2 and Embodiment 1 is described below; the difference between Embodiment 2 and Embodiment 1 is:

[0056] Further, such as image 3 As shown, the frame 100 is provided with several slide rails 11 corresponding to each heat reflection mechanism 4, and the bottoms at both ends of the heat reflection mechanism 4 can be erected on the slide rails 11 respectively, and drive the radiation heating Mechanism 3 slides in or out sideways.

[0057] Further, the bracket 31 is vertically penetrated and slidably installed on the heat reflection mechanism 4 , and a lifting adjustment block 30 is arranged on the bracket 31 below the heat reflection mechanism 4 .

[0058] In this embodiment, the radiation heating mechanism 3 and the heat reflection mechanism 4 are set as a one-piece structure. Specifically, the four corners of the bracket 31 penetrate longitudinally and are slidably arranged at the four corners of the botto...

Embodiment 3

[0063] For the sake of brevity, only the differences between Embodiment 3 and Embodiment 1 are described below; the differences between Embodiment 3 and Embodiment 1 are:

[0064] Further, such as figure 1 and Figure 7 As shown, it also includes a transmission overturning mechanism 5 arranged at the transmission end of the rotary conveyor mechanism 1, and the transmission overturning mechanism 5 includes a transmission component 51 transitionally connected with the rotary conveyor mechanism 1 and interlaced with the transmission component 51 The reversing assembly 52, the inverted battery pack 10 is transferred to the transmission assembly 51 and locked in the reversing assembly 52, driven by the reversing assembly 52 to turn over 180° and output in an upright state.

[0065] In this embodiment, by transitionally setting the transmission overturning mechanism 5 at the transmission end of the curing transmission production line, the inverted battery pack 10 after curing can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com