Manufacturing method of elliptical core polarization maintaining optical fiber

A polarization-maintaining optical fiber and manufacturing method technology, applied in the direction of manufacturing tools, glass manufacturing equipment, glass fiber products, etc., can solve the problems of difficult processing, poor stability, complex process, etc., and achieve strong anti-interference ability and stable temperature performance , The effect of reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

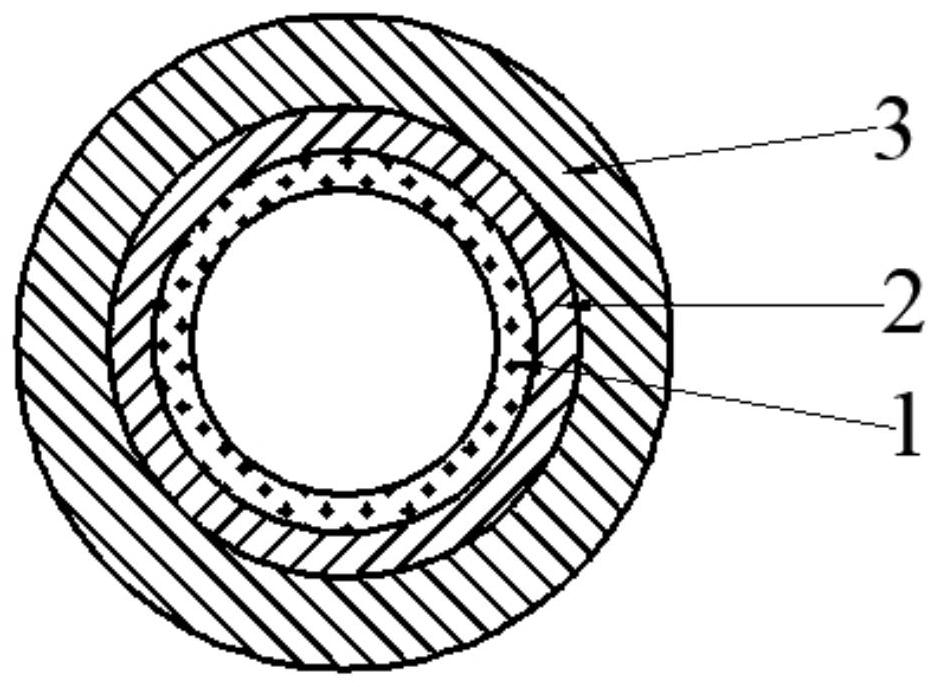

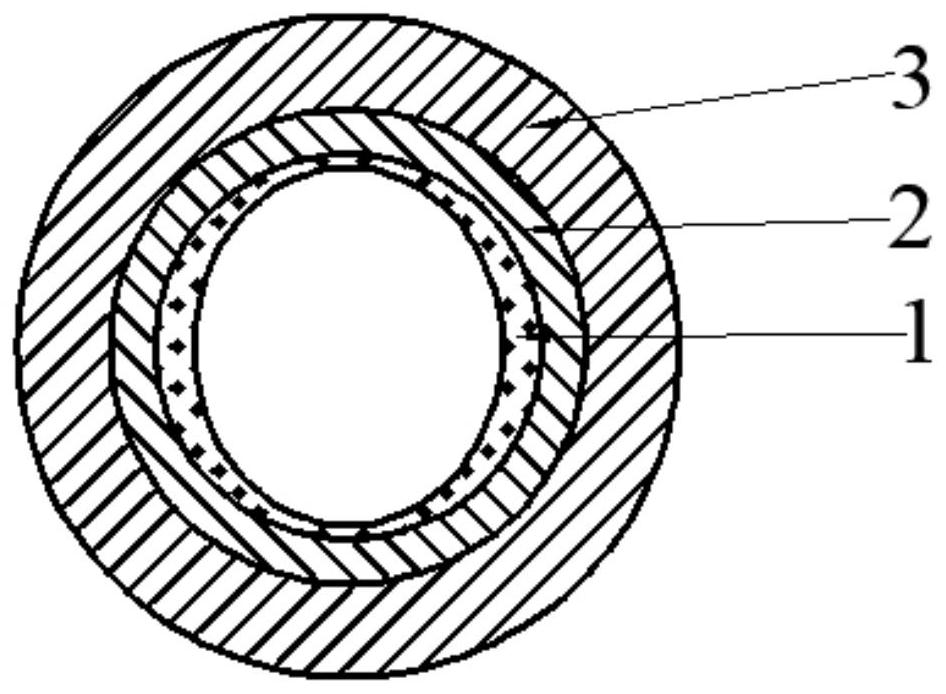

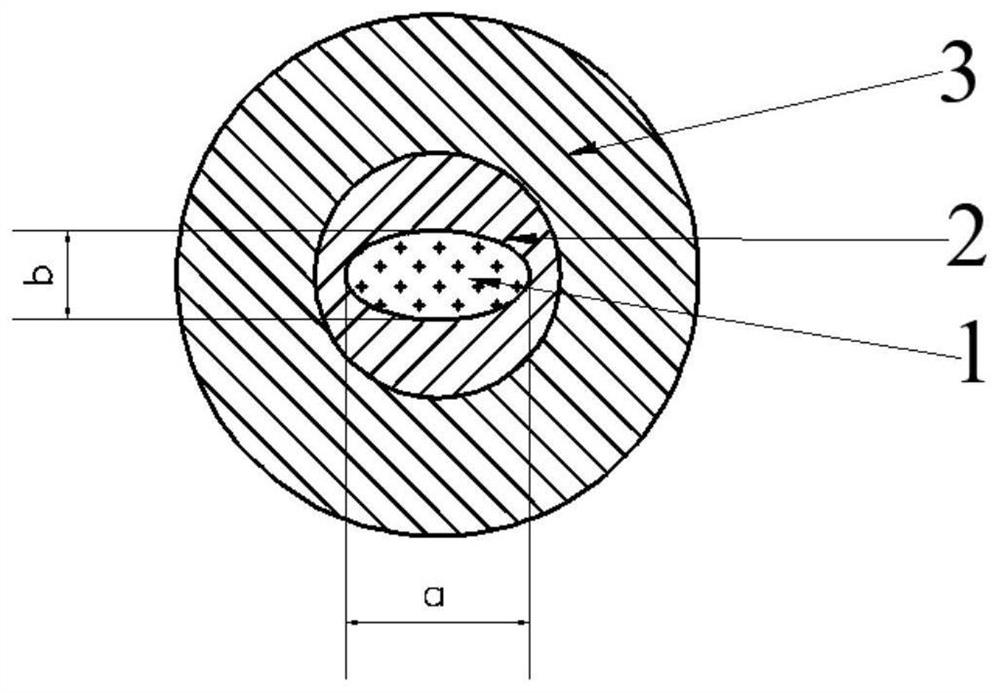

[0025] Embodiment 1, firstly carry out substrate tube 3 pretreatment on MCVD lathe by chemical vapor deposition method, then deposit core rod: first deposit the inner cladding layer 2 doped with fluorine, then deposit the core layer 1 co-doped with germanium and phosphorus, the deposited structure is as follows figure 1 As shown; then carry out directional etching, introduce sulfur hexafluoride corrosive gas, use a fire head outside the substrate tube to move back and forth along the substrate tube axis for etching, and control the heating time according to the etching size, and finally the germanium-phosphorus co- The doped core layer 1 is etched into an ellipse, and the result after etching is as follows figure 2 shown; followed by the forward collapse and reverse collapse processes to obtain an elliptical core light rod, such as image 3 As shown; then the elliptical core optical rod is sleeved, and the sleeve 4 is pure silica glass, which is combined to form an elliptical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com