Flame-retardant polyvinyl chloride insulation shielding control cable material

A polyvinyl chloride, insulation and shielding technology, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of low flame retardancy and unsafe ignition, and achieve enhanced weather resistance and chemical resistance The effect of high and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

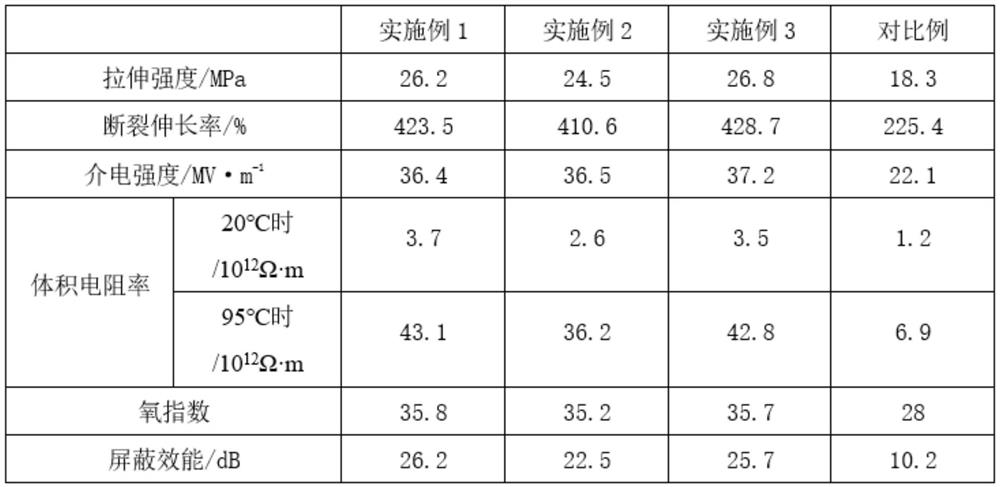

Embodiment 1

[0046] A flame-retardant polyvinyl chloride insulated and shielded control cable material, the cable material is composed of the following components in parts by weight:

[0047] 65 parts of modified polyvinyl chloride, 35 parts of chlorinated polyvinyl chloride, 18 parts of flame retardant, 25 parts of electromagnetic shielding material, 3 parts of lubricant and 0.2 part of antioxidant.

[0048]The preparation method of described modified polyvinyl chloride is:

[0049] S1. Weigh polyvinyl chloride powder and add it to N,N-dimethylformamide, stir evenly and then ultrasonically disperse for 1-2 hours to obtain polyvinyl chloride mixed liquid;

[0050] Wherein, the mass ratio of polyvinyl chloride powder to N,N-dimethylformamide is 1:4-6;

[0051] S2. Weigh 2,2-dimethoxypropane and add it dropwise to the polyvinyl chloride mixture, stir while adding dropwise, after the dropwise addition, add rhenium pentacarbonyl chloride, stir until completely dissolved, then heat up to 50-6...

Embodiment 2

[0080] A flame-retardant polyvinyl chloride insulated and shielded control cable material, the cable material is composed of the following components in parts by weight:

[0081] 55 parts of modified polyvinyl chloride, 25 parts of chlorinated polyvinyl chloride, 10 parts of flame retardant, 15 parts of electromagnetic shielding material, 1 part of lubricant and 0.05 part of antioxidant.

[0082] The preparation method of described modified polyvinyl chloride is:

[0083] S1. Weigh polyvinyl chloride powder and add it to N,N-dimethylformamide, stir evenly and then ultrasonically disperse for 1-2 hours to obtain polyvinyl chloride mixed liquid;

[0084] Wherein, the mass ratio of polyvinyl chloride powder to N,N-dimethylformamide is 1:4-6;

[0085] S2. Weigh 2,2-dimethoxypropane and add it dropwise to the polyvinyl chloride mixture, stir while adding dropwise, after the dropwise addition, add rhenium pentacarbonyl chloride, stir until completely dissolved, then heat up to 50-...

Embodiment 3

[0114] A flame-retardant polyvinyl chloride insulated and shielded control cable material, the cable material is composed of the following components in parts by weight:

[0115] 80 parts of modified polyvinyl chloride, 50 parts of chlorinated polyvinyl chloride, 20 parts of flame retardant, 30 parts of electromagnetic shielding material, 6 parts of lubricant and 0.5 part of antioxidant.

[0116] The preparation method of described modified polyvinyl chloride is:

[0117] S1. Weigh polyvinyl chloride powder and add it to N,N-dimethylformamide, stir evenly and then ultrasonically disperse for 1-2 hours to obtain polyvinyl chloride mixed liquid;

[0118] Wherein, the mass ratio of polyvinyl chloride powder to N,N-dimethylformamide is 1:4-6;

[0119] S2. Weigh 2,2-dimethoxypropane and add it dropwise to the polyvinyl chloride mixture, stir while adding dropwise, after the dropwise addition, add rhenium pentacarbonyl chloride, stir until completely dissolved, then heat up to 50-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com