Resonance device and resonance device manufacturing method

A technology of a resonant device and a manufacturing method, which is applied in the directions of manufacturing tools, microstructure devices, and manufacturing microstructure devices, etc., can solve the problems of dislocation of eutectic composition, reduction of vacuum degree, inability to heat treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described below. In the following description of the drawings, the same or similar structural elements are denoted by the same or similar reference numerals. The drawings are illustrative, and the dimensions and shapes of each part are schematic, and should not be interpreted as limiting the technical scope of the present invention to this embodiment.

[0022]

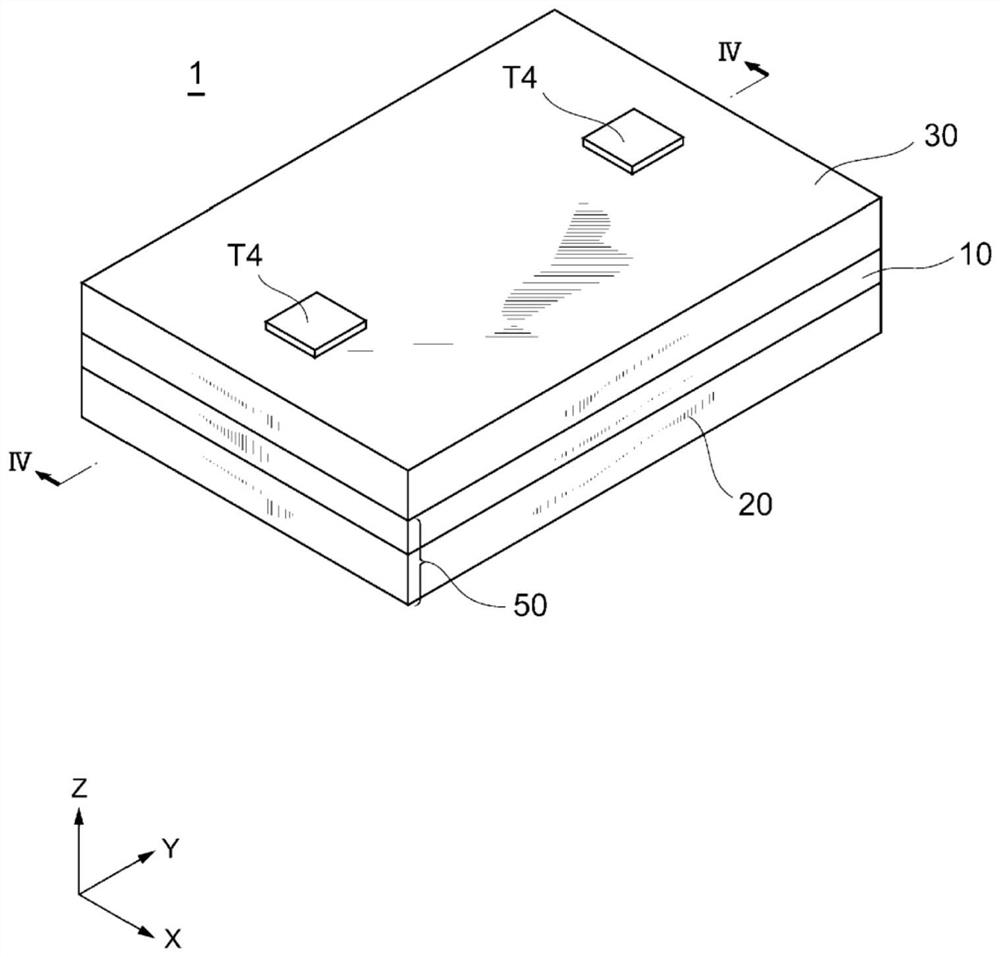

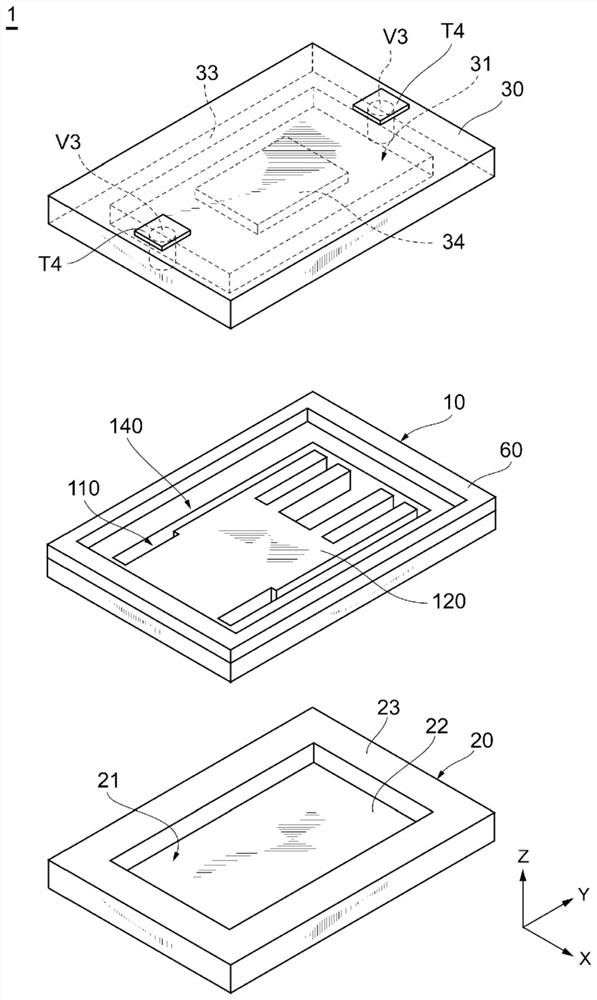

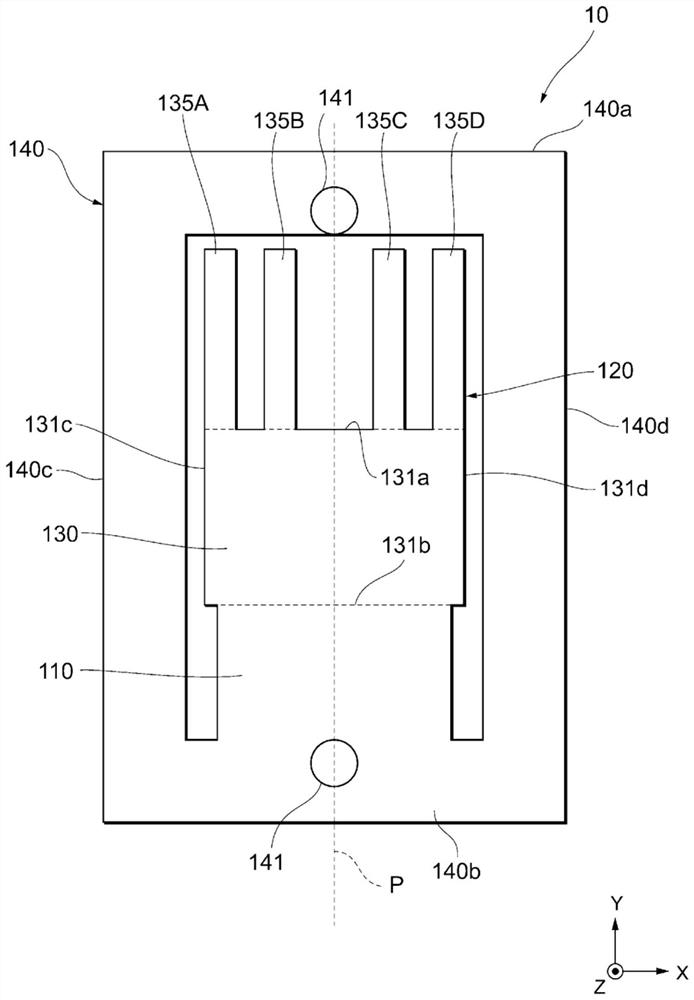

[0023] First, refer to figure 1 and figure 2 , the schematic configuration of the resonator device 1 according to one embodiment of the present invention will be described. figure 1 It is a perspective view schematically showing the appearance of the resonator device 1 according to one embodiment of the present invention. in addition, figure 2 It is an exploded perspective view schematically showing the structure of the resonator device 1 according to one embodiment of the present invention.

[0024] The resonator device 1 includes a lower cover 20 , a resona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com