A preparation method of lithium ion imprinted nanocomposite film with high adsorption capacity

A nano-composite, lithium-ion technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low lithium ion adsorption capacity and poor lithium ion selective adsorption effect, and achieve obvious selectivity effect , performance improvement, and the effect of increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

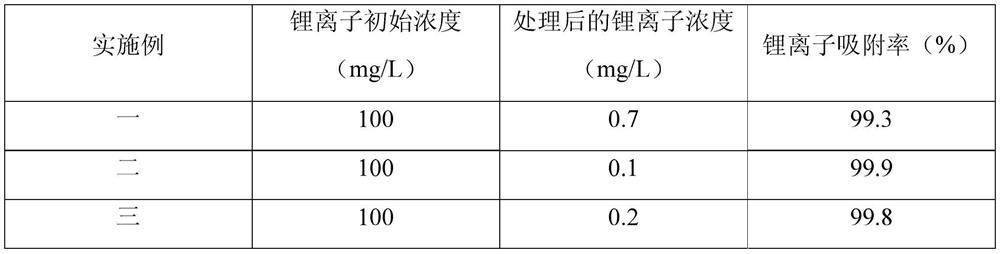

Examples

specific Embodiment approach 1

[0012] Specific implementation mode 1: In this implementation mode, a method for preparing a lithium ion imprinted nanocomposite membrane with high adsorption capacity is completed according to the following steps:

[0013] 1. Preparation of acidified MWCNTs: Add multi-walled carbon nanotubes to hydrochloric acid solution, ultrasonically treat for 15min-20min, then stir in a water bath at 25°C-30°C at a speed of 60r / min-80r / min for 24h, and dry. Obtain acidified MWCNTs;

[0014] 2. Preparation of MWCNTs@PDA@PVDF membrane: Add PDA@PVDF membrane and acidified MWCNTs to methanol solution, stir in a water bath at 25°C-30°C for 3h-4h at a speed of 60r / min-80r / min, and use Washing with deionized water and drying to obtain MWCNTs@PDA@PVDF membrane, the quality of the PDA@PVDF membrane, the quality of acidified MWCNTs and the volume ratio of methanol solution is 0.25g: (1g ~ 2g): (60mL ~ 80mL);

[0015] 3. Preparation of lithium-ion imprinted nanocomposite membrane with high adsorpt...

specific Embodiment approach 2

[0019] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the ratio of the mass of multi-walled carbon nanotubes described in step one to the volume of hydrochloric acid solution is (1.5g~3g): (80mL~100mL), The concentration of hydrochloric acid solution is 0.1mol / L.

[0020] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, acidified MWCNTs are obtained by drying at 80° C. to 100° C. for 4 hours to 6 hours.

[0022] Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com