Synthesis method and application of dimercaptothiadiazole sodium salt

A technology of sodium dimercaptothiadiazole, synthesis method, applied in chemical instruments and methods, water/sludge/sewage treatment, organic chemistry, etc., can solve the problem of multiple wastes and pollutants, excessive carbon disulfide, and long reaction time and other problems, to achieve the effect of simple reaction operation, reduced production amount, and strong catalytic reaction ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: the synthesis of dimercaptothiadiazole sodium salt

[0043] 1. Prepare raw materials. After measuring 65Kg of raw material 80% hydrazine hydrate, vacuum inhale the low-temperature reactor and start stirring; Guanidine 195g and triisopropylamine 796g are measured respectively and added to the low-temperature reactor; carbon disulfide is pressed into the carbon disulfide metering tank from the storage tank with compressed air (it must be ensured that the height of the liquid seal water in the metering tank is not less than 15mm), and the amount of carbon disulfide is 159.5 mm. Kg;

[0044] 2. Dropping reaction Feed freezing liquid into the jacket of the low-temperature reaction kettle, wait until the temperature in the kettle drops to 10°C, start adding carbon disulfide dropwise, control the dropping speed, and maintain the reaction temperature at 22°C. Carbon disulfide was added dropwise within 52 minutes;

[0045] 3. Insulation reaction After the additio...

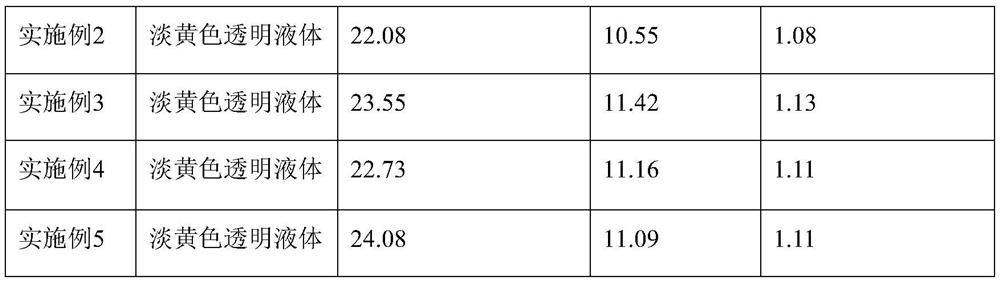

Embodiment 2

[0047] Embodiment 2: the synthesis of dimercaptothiadiazole sodium salt

[0048] 1. Prepare raw materials. After measuring 65Kg of raw material 80% hydrazine hydrate, vacuum inhale the low-temperature reactor and start stirring; 325g of guanidine and 1170g of triisopropylamine are measured respectively and added to the low-temperature reaction kettle; carbon disulfide is pressed from the storage tank into the carbon disulfide metering tank with compressed air (it must be ensured that the height of the liquid seal water in the metering tank is not less than 15mm), and the amount of carbon disulfide is 160Kg ;

[0049] 2. Dropping reaction Feed freezing liquid into the jacket of the low-temperature reaction kettle, wait until the temperature in the kettle drops to 12°C, start adding carbon disulfide dropwise, control the dropping speed, and maintain the reaction temperature at 32°C. Carbon disulfide was added dropwise within 72 minutes;

[0050] 3. Insulation reaction After th...

Embodiment 3

[0052] Embodiment 3: the synthesis of dimercaptothiadiazole sodium salt

[0053] 1. Prepare raw materials. After measuring 65Kg of raw material 80% hydrazine hydrate, vacuum inhale the low-temperature reactor, and start stirring; Measure 450g of guanidine and 650g of triisopropylamine respectively and add them to the low-temperature reaction kettle; use compressed air to press carbon disulfide from the storage tank into the carbon disulfide metering tank (it must be ensured that the height of the liquid seal water in the metering tank is not less than 15mm), and the amount of carbon disulfide is 160Kg ;

[0054] 2. Dropping reaction Feed freezing liquid into the jacket of the low-temperature reaction kettle, wait until the temperature in the kettle drops to 15°C, start adding carbon disulfide dropwise, control the dropping speed, and keep the reaction temperature at 28°C. Carbon disulfide was added dropwise within 60 minutes;

[0055]3. Insulation reaction After the addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com