Friction layer for improving electrical properties of nano-generator by utilizing composite interlayer and preparation method thereof

A technology of nanogenerator and friction layer, which is applied in the direction of tribogenerator and coating, can solve the problems that the tribogenerator needs to be further improved, and achieve the effect of improving output performance, realizing output performance and high output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

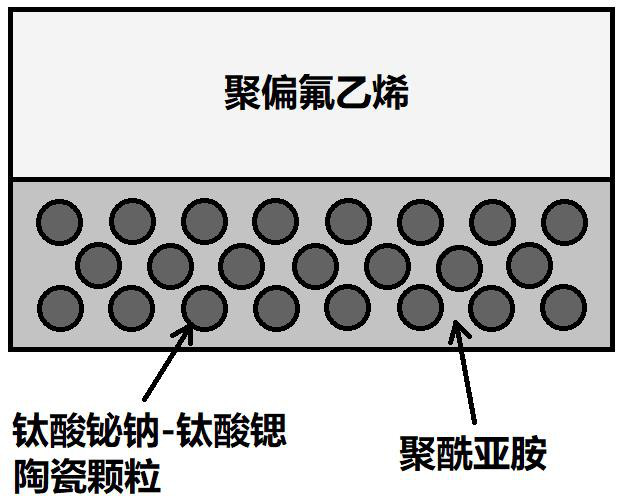

[0017] A method for preparing a friction layer using a composite interlayer to improve the electrical performance of a nanogenerator, comprising the steps of:

[0018] 1) Dissolve 1g of diaminodiphenyl ether and 1.09g of pyromellitic anhydride in 25ml of dimethylformamide, add a certain mass fraction of sodium bismuth titanate-strontium titanate micron ceramic particles, and stir for 12 hours to obtain titanium-containing Sodium bismuth acid-strontium titanate ceramic particles and a solid-liquid mixture of polyimide precursors;

[0019] 2) Electrostatically atomize the solid-liquid mixture obtained in step 1), apply a voltage of 10kV~20kV, and receive a distance of 8cm to obtain a composite film precursor;

[0020] 3) The composite film precursor obtained in step 2) was hot-pressed at 60MPa and 80°C for 2h, kept at 100°C for 1h, kept at 150°C for 1h, kept at 200°C for 2h, kept at 250°C for 2h, and finally kept at 300°C 2h, polyimide@sodium bismuth titanate-strontium titanate...

Embodiment 1

[0023] 1) Dissolve 1g of diaminodiphenyl ether and 1.09g of pyromellitic anhydride in 25ml of dimethylformamide, add a certain mass fraction of sodium bismuth titanate-strontium titanate micron ceramic particles, and stir for 12 hours to obtain titanium-containing Sodium bismuth acid-strontium titanate ceramic particles and a solid-liquid mixture of polyimide precursors;

[0024] 2) Electrostatically atomize the solid-liquid mixture obtained in step 1), apply a voltage of 15kV, and receive a distance of 8cm to obtain a composite film precursor;

[0025] 3) The composite film precursor obtained in step 2) was hot-pressed at 60MPa and 80°C for 2h, kept at 100°C for 1h, kept at 150°C for 1h, kept at 200°C for 2h, kept at 250°C for 2h, and finally kept at 300°C 2h, polyimide@bismuth sodium titanate-strontium titanate composite interlayer was obtained, and the mass fraction of bismuth sodium titanate-strontium titanate micron ceramic particles in the composite interlayer was 60%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com