Methanol, condensate oil and high mineralized water resistant compound betaine foam scrubbing agent special for oil and gas fields and preparation method thereof

A technology for resistance to methanol and oil and gas fields, applied in the directions of chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in meeting drainage and gas production processes, and achieve the effect of improving resistance to high methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Prepare oil and gas field special anti-methanol, condensate oil, highly mineralized water compound betaine foaming agent according to the following method:

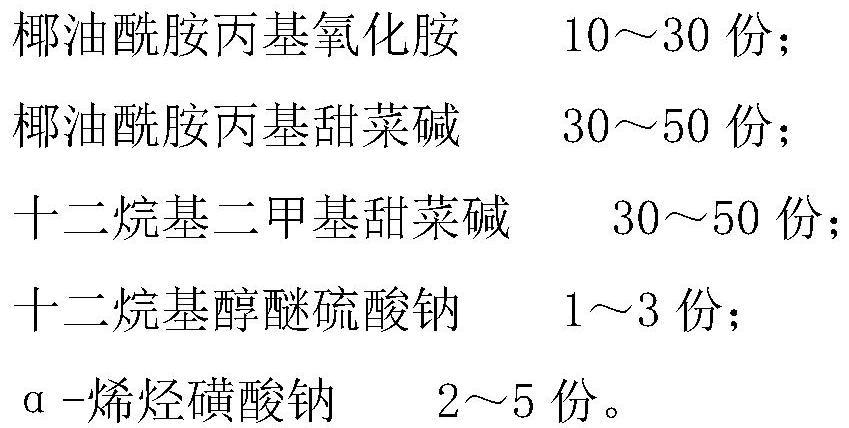

[0020] S1: Measure each component according to the mass ratio of raw materials for production as follows:

[0021]

[0022]

[0023] S2: Add the production raw materials into the mixing container, stir at 60°C for 30 minutes, and wait until the materials in the reaction container are fully mixed and uniform to obtain the foam discharge agent sample.

[0024] S3: Test the anti-foaming performance of the obtained foaming agent sample against high methanol, high condensate oil, and high mineralized water. The test results are shown in Table 1.

Embodiment 2

[0026] Prepare oil and gas field special anti-methanol, condensate oil, highly mineralized water compound betaine foaming agent according to the following method:

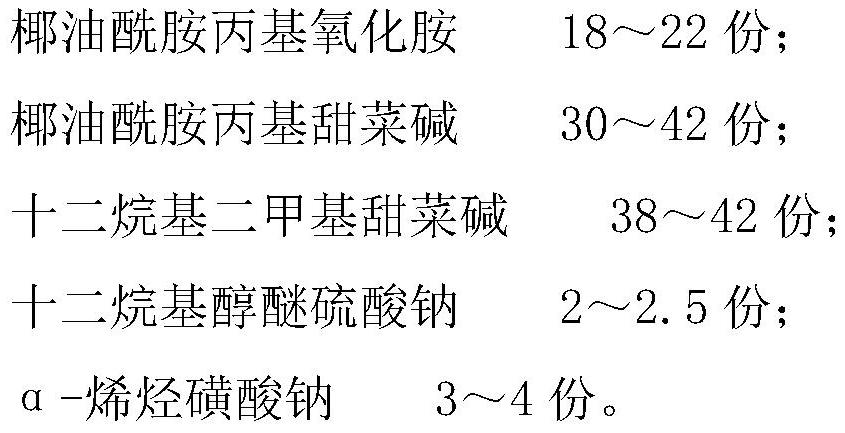

[0027] S1: Measure each component according to the mass ratio of raw materials for production as follows:

[0028]

[0029] S2: Add the production raw materials into the mixing container, stir at 60°C for 30 minutes, and wait until the materials in the reaction container are fully mixed and uniform to obtain the foam discharge agent sample.

[0030] S3: Test the anti-foaming performance of the obtained foaming agent sample against high methanol, high condensate oil, and high mineralized water. The test results are shown in Table 1.

Embodiment 3

[0032] Prepare oil and gas field special anti-methanol, condensate oil, highly mineralized water compound betaine foaming agent according to the following method:

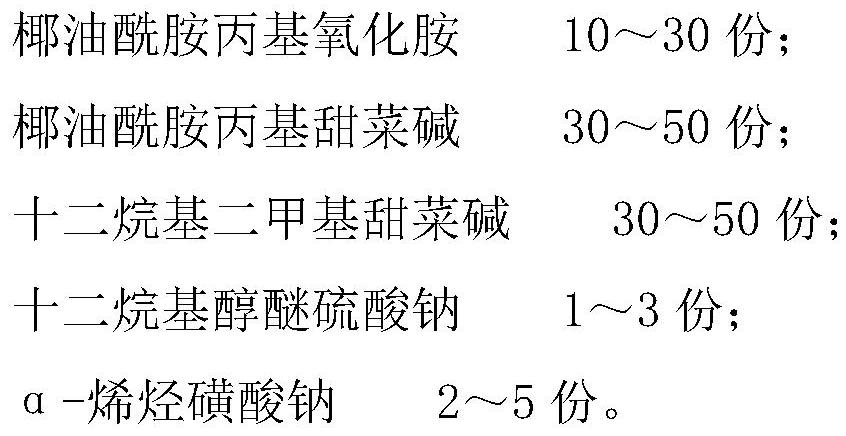

[0033] S1: Measure each component according to the mass ratio of raw materials for production as follows:

[0034]

[0035] S2: Add the production raw materials into the mixing container, stir at 60°C for 30 minutes, and wait until the materials in the reaction container are fully mixed and uniform to obtain the foam discharge agent sample.

[0036] S3: Test the anti-foaming performance of the obtained foaming agent sample against high methanol, high condensate oil, and high mineralized water. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com