A q420c-grade hot-rolled angle steel and its preparation method based on machine learning

A machine learning, angle steel technology, applied in the field of angle steel manufacturing, can solve the problems of low yield strength and angle steel specifications, poor use effect of large sample data, low yield strength angle steel specifications, etc., to reduce production costs, good precipitation strengthening effect, reduce The effect of adding

- Summary

- Abstract

- Description

- Claims

- Application Information

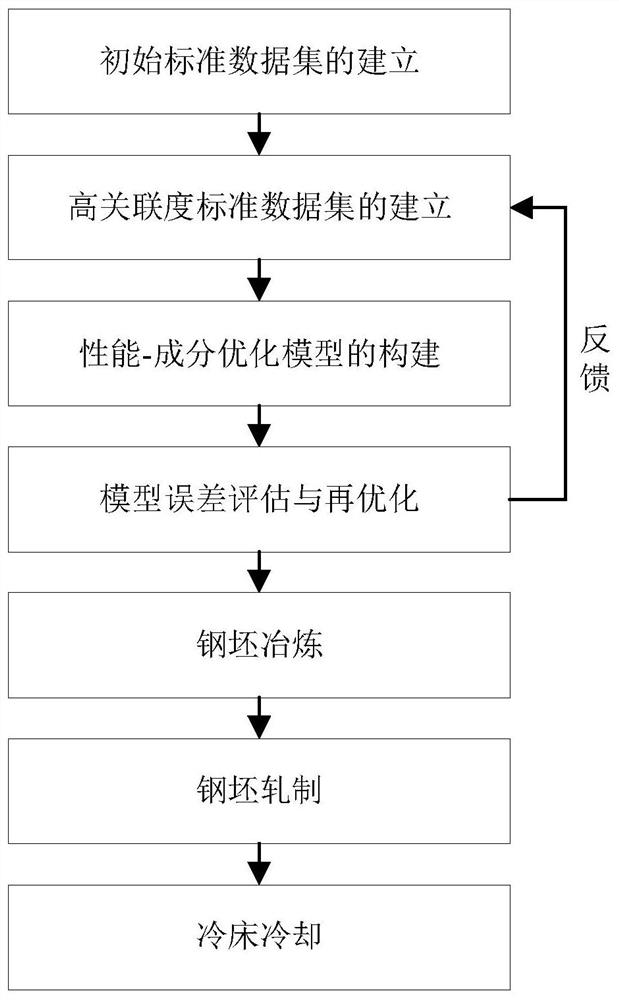

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1: After using the GRA-ELM model to optimize the elemental composition of Q420C hot-rolled angle steel, smelting and casting according to the above composition range to obtain a continuous casting billet with a cross-section of 250×350 mm, and then detecting the composition of the billet, see Table 1.

[0056] Composition (wt.%) of billet of table 1

[0057]

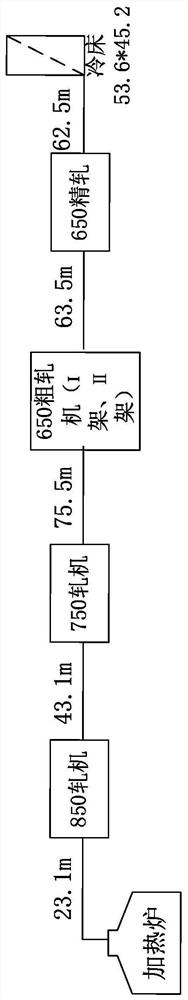

[0058] Rolling is carried out in accordance with the sequence of 850 / 750 / 650I / 650Ⅱ / 650 finishing mills, and the rolling passes are 5 / 3 / 2 / 1 / 1 respectively. After rolling, the angle steel with the specification of ∠220*∠220*20 is obtained. The properties are shown in Table 2.

[0059] Table 2 Mechanical Properties

[0060]

Embodiment 2

[0061] Example 2: After using the GRA-ELM model to optimize the element composition of Q420C large-scale hot-rolled angle steel, smelting and casting according to the above-mentioned composition range to obtain a billet with a cross-section of 250×350mm, and then detecting the composition of the billet, see Table 3.

[0062] Composition (wt.%) of billet of table 3

[0063]

[0064] Rolling is carried out in accordance with the sequence of 850 / 750 / 650I / 650Ⅱ / 650 finishing mills, and the rolling passes are 5 / 3 / 2 / 1 / 1 respectively. After rolling, the angle steel with the specification of ∠250*∠250*24 is obtained. The properties are shown in Table 4.

[0065] Table 4 mechanical properties

[0066]

Embodiment 3

[0067] Example 3: After using the GRA-ELM model to optimize the element composition of Q420 large-scale hot-rolled equilateral angle steel, smelting and casting according to the above-mentioned composition range to obtain a steel billet with a cross-section of 250×350 mm, and then detecting the composition of the steel billet, See Table 5.

[0068] Composition (wt.%) of billet of table 5

[0069]

[0070] Rolling is carried out in accordance with the sequence of 850 / 750 / 650I / 650Ⅱ / 650 finishing mills, and the rolling passes are 5 / 3 / 2 / 1 / 1 respectively. After rolling, the angle steel with the specification of ∠220*∠220*24 is obtained. The properties are shown in Table 6.

[0071] Table 6 mechanical properties

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com