A positive electrode for high specific energy and rapid activation of seawater battery and its preparation method

A seawater battery and cathode technology, which is applied in the field of high specific energy and rapid activation of seawater batteries, can solve the problems of low specific energy, low activation performance at discharge rate, and difficulty in meeting market demands, and achieves shortened activation time, improved specific energy, and improved activation. fast time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

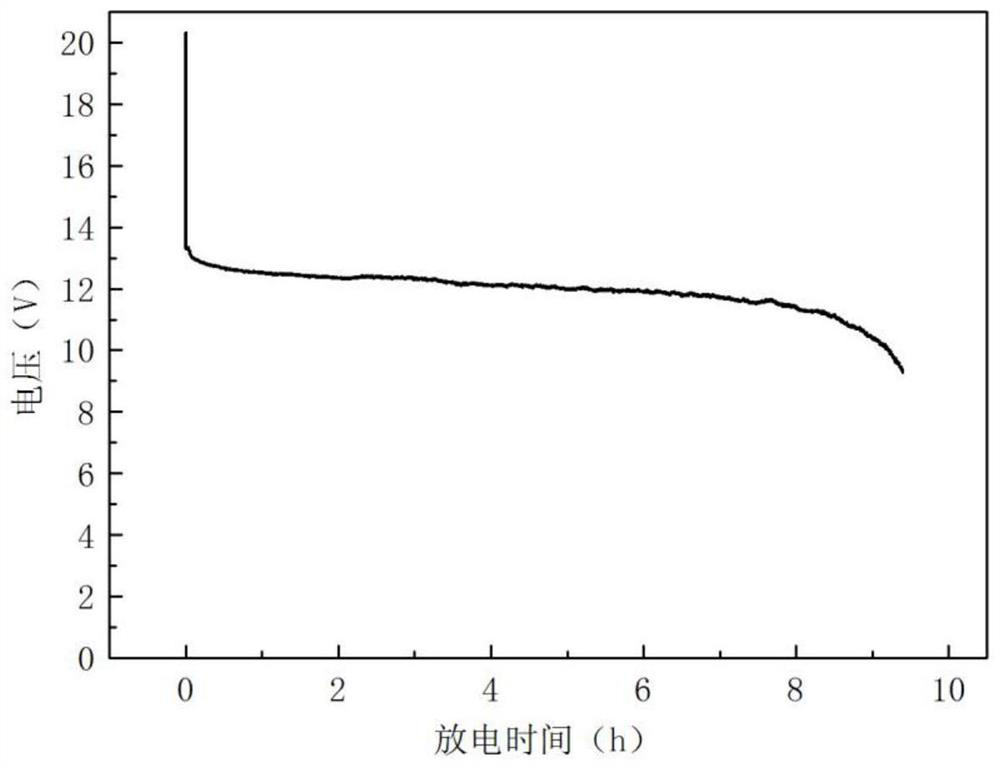

[0034] Example 1: Put lead chloride in a ball mill tank, control the ball-to-material ratio between 0.6:1 and 2:1, ball mill for 2 hours, and sieve. Take 30.67g of ground lead chloride, add carbon nanotubes and silver-plated copper powder in a ratio of 1:4, ball mill evenly, then add the binder polytetrafluoroethylene, and stir evenly. Put the mixed positive electrode powder into the mold, adjust the parameters of the press, press and form the positive electrode powder cake, wrap the positive electrode powder cake with copper mesh, put it into the customized mold, adjust the press parameters, and press and form the positive electrode sheet. The positive electrode sheet was baked at 70°C for 21 hours to obtain the positive electrode sheet described in this patent with good specific energy and activation performance. The pole piece and the magnesium plate form a seawater battery, and the positive and negative leads are welded for battery testing. The formula battery is discharg...

Embodiment 2

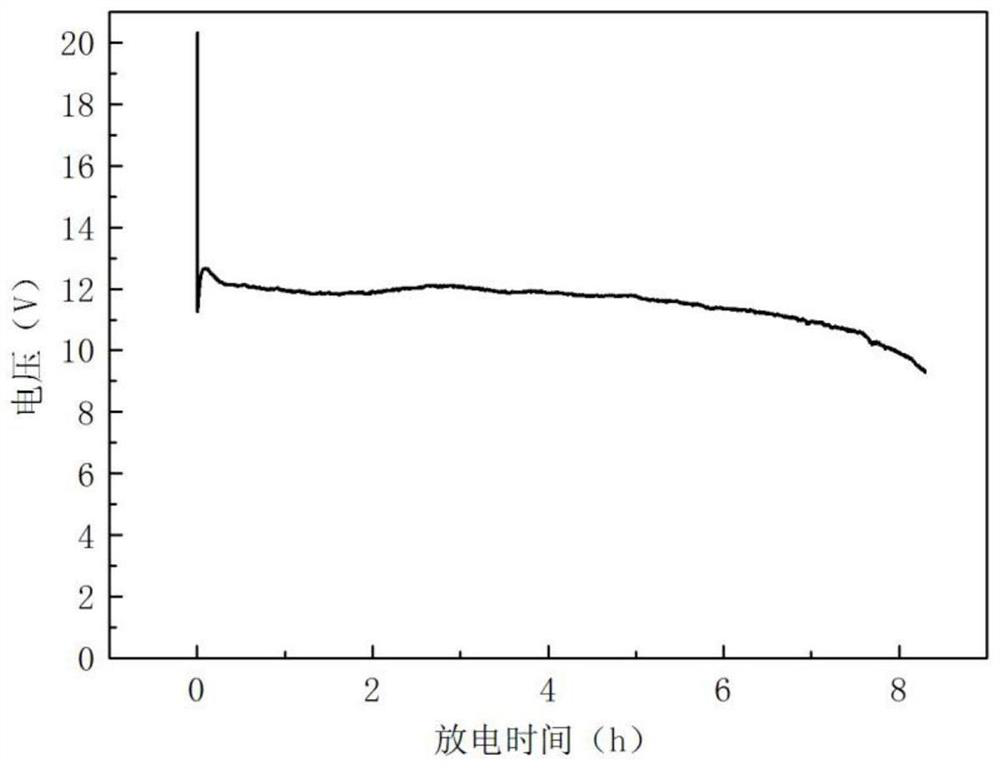

[0035] Example 2: Put lead chloride in a ball mill tank, control the ball-to-material ratio between 0.6:1 and 2:1, ball mill for 2 hours, and sieve. Take 30.67g of ground lead chloride, add carbon nanotubes and silver-plated copper powder in a ratio of 1:3, ball mill evenly, then add the binder polytetrafluoroethylene, and stir evenly. Put the mixed positive electrode powder into the mold, adjust the parameters of the press, press and form the positive electrode powder cake, wrap the positive electrode powder cake with copper mesh, put it into the customized mold, adjust the press parameters, and press and form the positive electrode sheet. The positive electrode sheet was baked at 70°C for 21 hours to obtain the positive electrode sheet described in this patent with good specific energy and activation performance. The pole piece and the magnesium plate form a seawater battery, and the positive and negative leads are welded for battery testing. The formula battery is discharg...

Embodiment 3

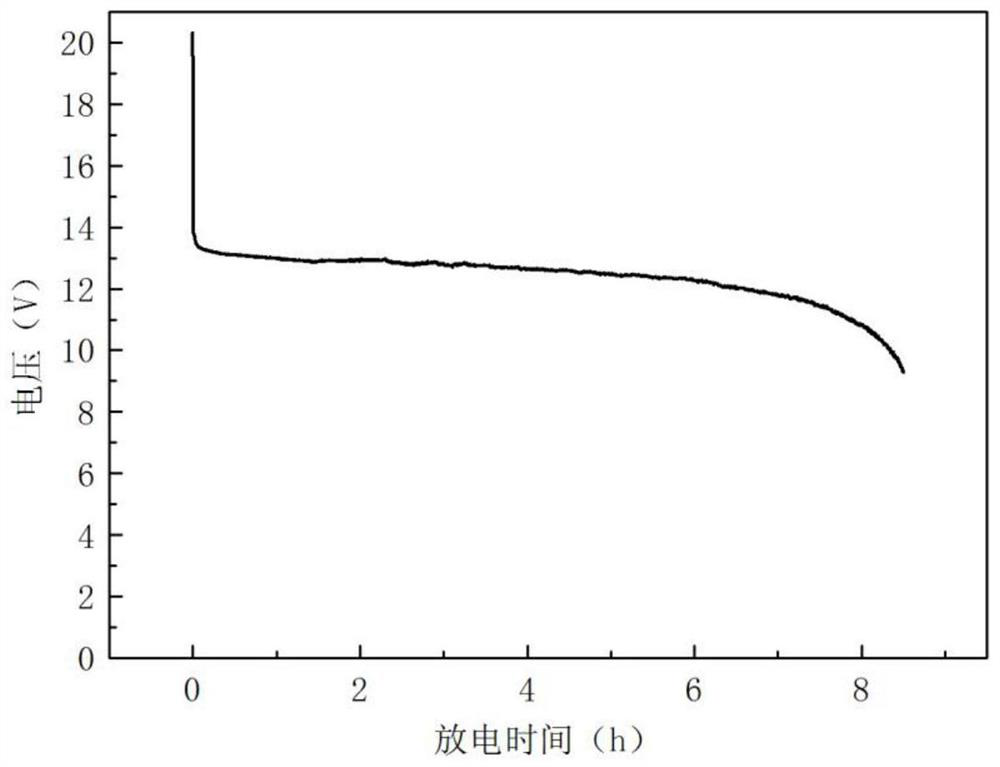

[0036] Example 3: Put lead chloride in a ball mill tank, control the ball-to-material ratio between 0.6:1 and 2:1, ball mill for 2 hours, and sieve. Take 33.47g of ground lead chloride, add 0.9g of carbon nanotubes, ball mill evenly, then add binder polytetrafluoroethylene, and stir evenly. Put the mixed positive electrode powder into the mold, adjust the parameters of the press, press and form the positive electrode powder cake, wrap the positive electrode powder cake with copper mesh, put it into the customized mold, adjust the press parameters, and press and form the positive electrode sheet. The positive electrode sheet was baked at 70°C for 21 hours to obtain the positive electrode sheet described in this patent with good specific energy and activation performance. The pole piece and the magnesium plate form a seawater battery, and the positive and negative leads are welded for battery testing. The formula battery is discharged at room temperature, the activation time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com