Aluminum-air battery electrolyte as well as preparation method and application thereof

An aluminum-air battery and electrolyte technology, which is applied in the directions of alkaline electrolyte, aqueous electrolyte, fuel cell-type half-cell and primary battery-type half-cell, etc. Widespread and other problems, to achieve the effect of delaying hydrogen evolution corrosion and high open circuit potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

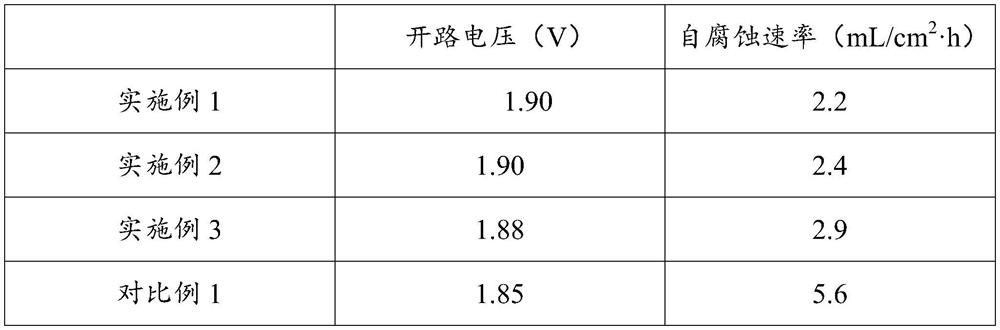

Embodiment 1

[0017] Prepare 4mol / L potassium hydroxide aqueous solution, add 0.2g / L sodium stannate, ultrasonically dissolve, add 0.2g / L potassium oleate, stir to dissolve, then add 0.2g / L lauryl glucoside, heat up to 45°C , stir to dissolve, cool to room temperature, finally add zinc oxide 0.08g / L, stir to dissolve, and make an electrolyte.

Embodiment 2

[0019] Prepare 4mol / L potassium hydroxide aqueous solution, add sodium stannate 0.2g / L, ultrasonically dissolve, add potassium oleate 0.3g / L, stir to dissolve, then add lauryl glucoside 0.3g / L, heat up to 45°C , stir to dissolve, cool to room temperature, finally add zinc oxide 0.05g / L, stir to dissolve, and make an electrolyte.

Embodiment 3

[0021] Prepare 4mol / L potassium hydroxide aqueous solution, add 0.1g / L sodium stannate, ultrasonically dissolve, add 0.1g / L potassium oleate, stir to dissolve, then add 0.2g / L lauryl glucoside, heat up to 45°C , stir to dissolve, cool to room temperature, finally add zinc oxide 0.05g / L, stir to dissolve, and make an electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com