A kind of preparation method and battery device of aluminum-air battery cathode catalyst

A cathode catalyst and aluminum-air battery technology, applied in fuel cell half-cells and primary battery half-cells, battery electrodes, circuits, etc., can solve problems such as inability to achieve synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

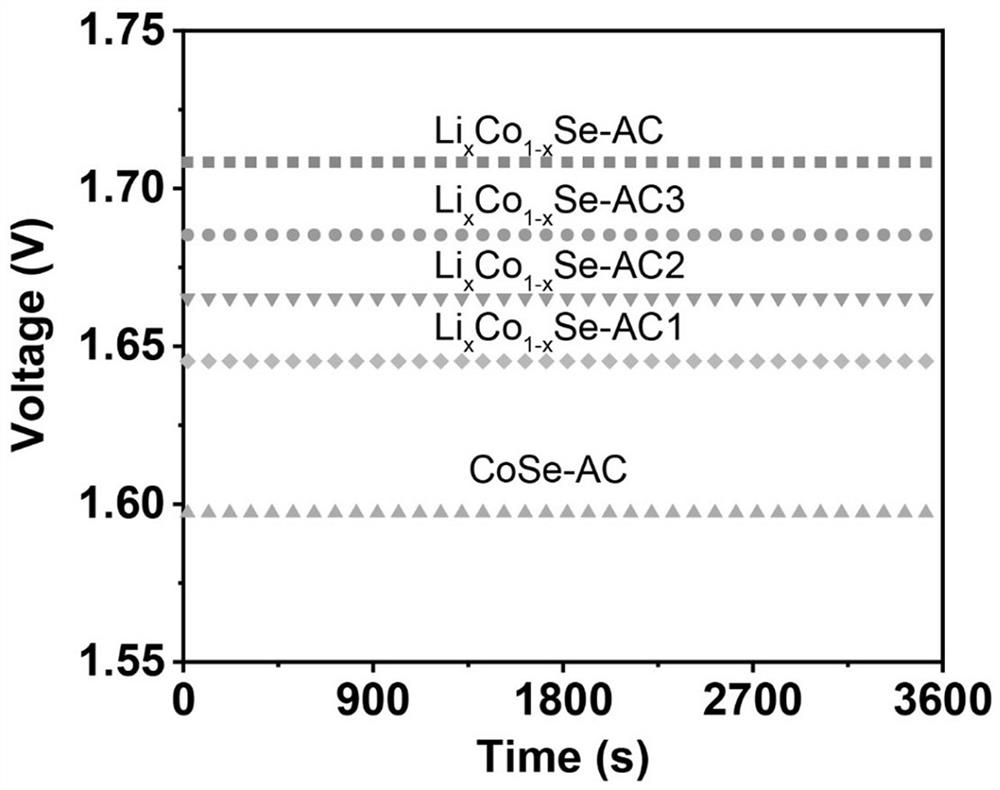

Embodiment 1

[0025] An aluminum-air battery cathode catalyst, the preparation method of which comprises the following steps:

[0026] (1) Weigh 150 mg of acetylene black, 1.5 mmol of cobalt chloride hexahydrate, 0.03 mmol of lithium chloride and 1.53 mmol of sodium selenite, add them to 60 mL of deionized water and sonicate for 0.5 h to make them uniformly dispersed, and then add 8 50% hydrazine hydrazine solution, continue to be sonicated for 0.5 h, then transferred to the reaction kettle, and placed in an oven for a hydrothermal reaction with a reaction temperature of 140 °C and a reaction time of 16 h. Washed with ionized water, then dried in an oven at 50°C overnight;

[0027] (2) Transfer the dried sample in step (1) to a corundum porcelain boat, and then in a nitrogen protective atmosphere at 5 ℃ min -1 The heating rate was increased to 600 °C and maintained for 1 h for heat treatment to obtain the aluminum-air battery cathode catalyst, which was marked as Li x Co 1-x Se-AC.

Embodiment 2

[0029] In step (1), 0.01 mmol lithium chloride and 1.51 mmol sodium selenite were added; other preparation process and parameters were the same as in Example 1; marked as Li x Co 1-x Se-AC1.

Embodiment 3

[0031] In step (1), 0.02 mmol lithium chloride and 1.52 mmol sodium selenite were added; other preparation process and parameters were the same as in Example 1; marked as Li x Co 1-x Se-AC2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com