Ridge holing device

A technology of working device and driving device, which is applied in agriculture, planting methods, excavation/covering of trenches, etc. Hole effect, the effect of avoiding soil backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

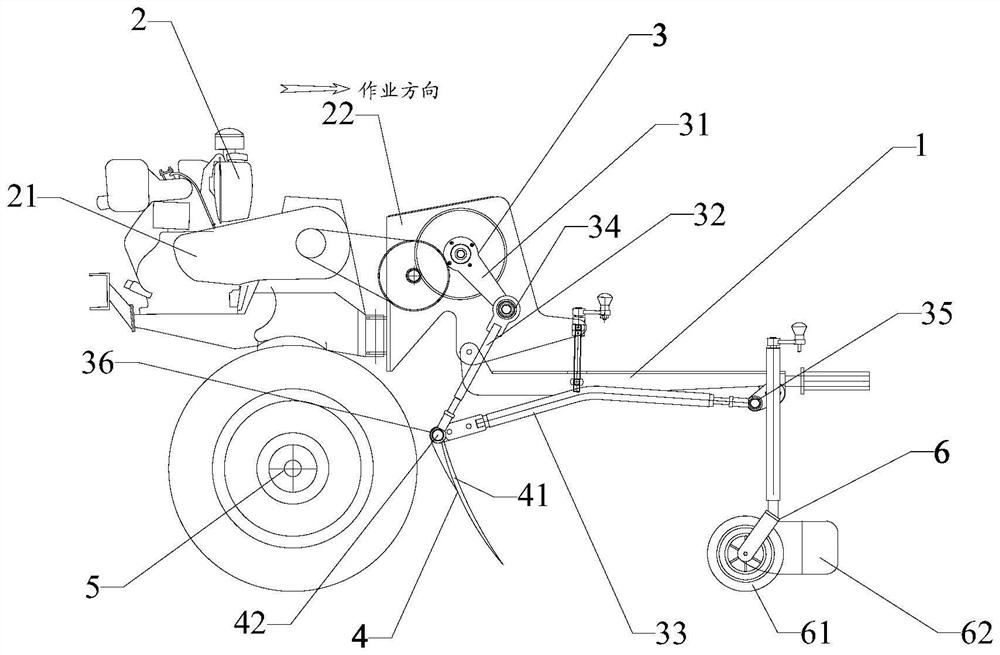

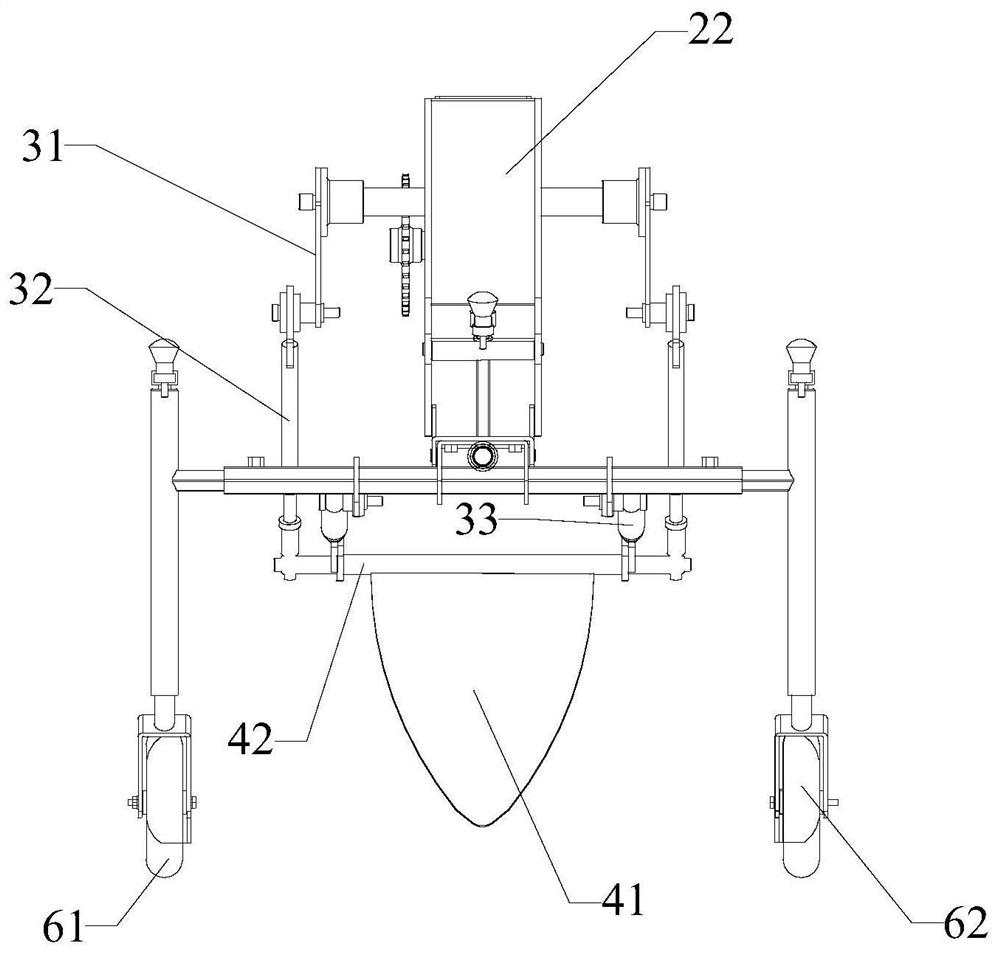

[0043] A ground ridge punching operation device, comprising a frame 1, a driving device 2, a transmission assembly 3, a hole punching shovel mechanism 4 and a driving wheel 5; the driving device 2 is connected to the frame 1, and the driving wheel 5 is connected to Frame 1, the drive wheel 5 is in transmission connection with the drive device 2, and the frame 1 advances along the working direction driven by the drive device 2; the transmission assembly 3 includes a crank 31, a connecting rod 32 and a rocker 33, One end of the crank 31 is in transmission connection with the driving device 2, and the crank 31 rotates under the drive of the driving device 2, and one end of the connecting rod 32 is hinged to the other end of the crank 31 through the first articulated bearing 34; The shovel mechanism 4 is fixedly connected with the connecting rod 32, one end of the rocking lever 33 is hinged to the frame 1 through the second hinged bearing 35, and the other end is hinged to the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com