Method for stripping Bi3O4Cl by using cell disintegrator and application of method in aspect of photocatalytic reduction of CO2

A pulverizer, photocatalytic technology, applied in catalyst activation/preparation, physical/chemical process catalyst, carbon monoxide, etc., can solve the problem of low photocatalytic efficiency, achieve high separation efficiency, fast migration rate, good photocatalytic reduction of CO2 performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

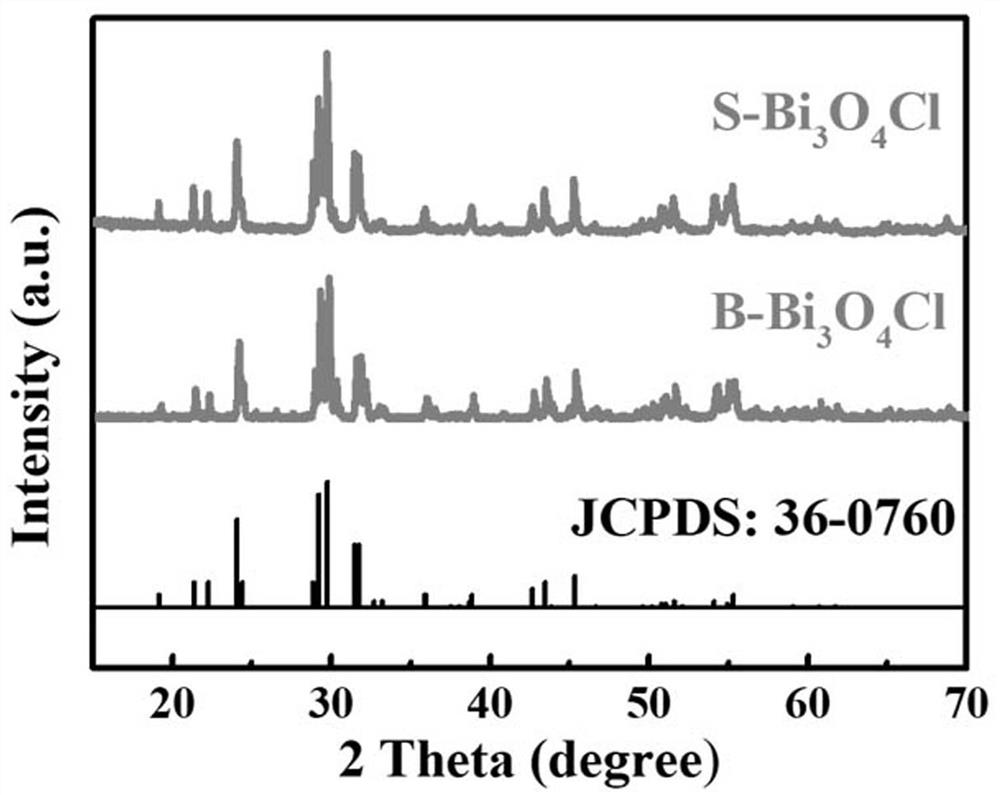

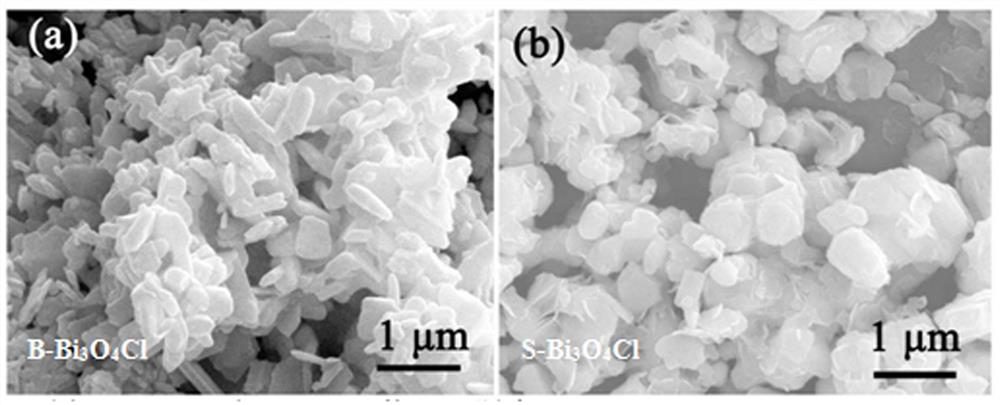

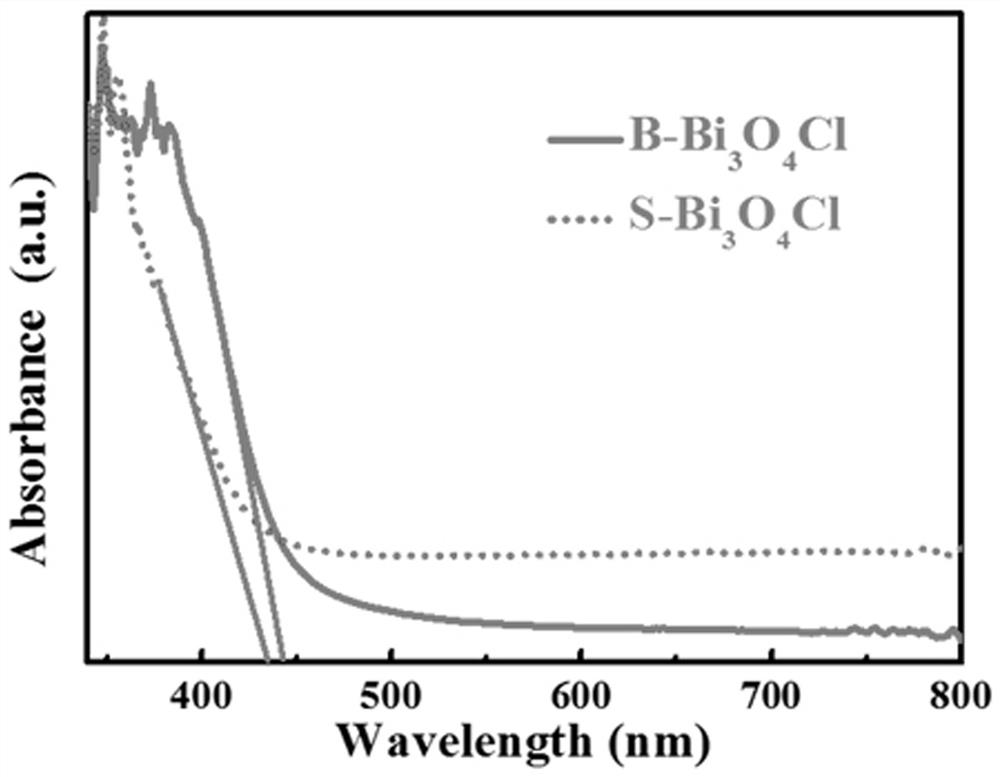

[0021] The present invention uses a cell pulverizer to peel off Bi 3 o 4 The method embodiment 1 of Cl, its method step is:

[0022] ⑴. Weigh 1 g Bi(NO 3 ) 3 ·5H 2O was fully stirred and dissolved in 35 ml of deionized water, then 0.5 g of tetracycline hydrochloride was added, stirred for 30 min, the mixture was transferred to a 40 ml polytetrafluoroethylene-lined stainless steel kettle, and reacted at 160 °C for 16 h. The samples after the hydrothermal reaction were taken out and centrifuged at 10,000 r / min for 10 min each time using a centrifuge. The centrifuged precipitate was washed several times with distilled water and ethanol, and finally dried in an oven at 80 °C for 24 h to obtain a black Bi-O-Cl complex precursor. Weigh 0.2 g of the dried precursor and put it into a muffle furnace for sintering at 550 °C for 3 h at a heating rate of 5 °C / min. After cooling down to room temperature naturally, collect the sample to obtain the bulk Bi 3 o 4 Cl photocatalyst;

[...

Embodiment 2

[0024] The present invention uses a cell pulverizer to peel off Bi 3 o 4 The method embodiment 2 of Cl, its method step is:

[0025] ⑴. Weigh 0.8 g Bi(NO 3 ) 3 ·5H 2 O was fully stirred and dissolved in 33 ml of deionized water, then 0.35 g of tetracycline hydrochloride was added, stirred for 40 min, the mixture was transferred to a 40 ml polytetrafluoroethylene-lined stainless steel kettle, and reacted at 180 °C for 16 h. The samples after the hydrothermal reaction were taken out and centrifuged at 10,000 r / min for 8 min each time using a centrifuge, and the centrifuged precipitates were washed several times with distilled water and ethanol respectively, and finally dried in an oven at 60 °C for 18 h to obtain black Bi- O-Cl complex precursor. Weigh 0.2 g of the dried precursor and put it into a muffle furnace for sintering at 500 °C for 5 h at a heating rate of 2 °C / min, and collect the sample after naturally cooling down to room temperature to obtain the bulk Bi 3 o ...

Embodiment 3

[0027] The present invention uses a cell pulverizer to peel off Bi 3 o 4 The method embodiment 3 of Cl, its method step is:

[0028] ⑴. Weigh 0.5 g Bi(NO 3 ) 3 ·5H 2 O was fully stirred and dissolved in 33 ml of deionized water, then 0.28 g of tetracycline hydrochloride was added, stirred for 30 min, the mixture was transferred to a 40 ml polytetrafluoroethylene-lined stainless steel kettle, and reacted at 180 °C for 24 h. The samples after the hydrothermal reaction were taken out and centrifuged at 10,000 r / min for 8 min each time using a centrifuge, and the centrifuged precipitates were washed several times with distilled water and ethanol respectively, and finally dried in an oven at 60 °C for 18 h to obtain black Bi- O-Cl complex precursor. Weigh 0.2 g of the dried precursor into a muffle furnace and sinter at 450 °C for 5 h with a heating rate of 1 °C / min, and collect samples after naturally cooling down to room temperature to obtain the bulk Bi 3 o 4 Cl photocatal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com