Mesoporous material composite thermal insulation adhesive and preparation method thereof

A mesoporous material and composite thermal insulation technology, applied in the field of materials, can solve the problems of the thermal insulation effect of the thermal insulation system, no thermal insulation, etc., and achieve the effect of improving the thermal insulation effect and reducing the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

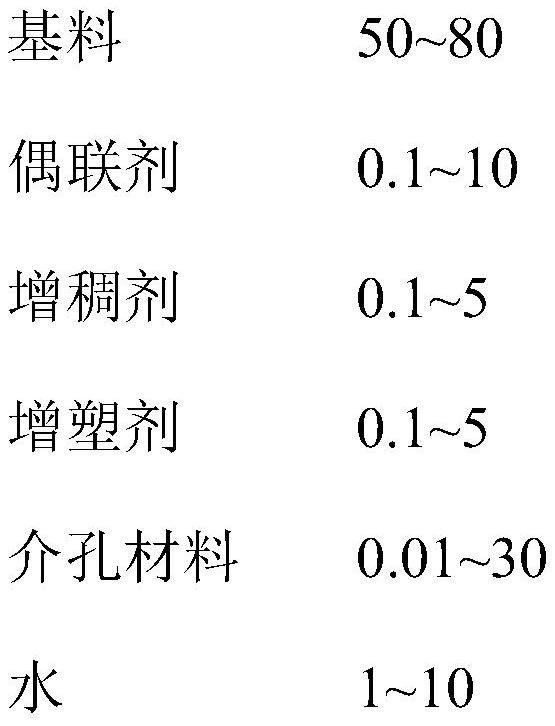

Method used

Image

Examples

Embodiment 1

[0014] Take 80 parts of water-based polyurethane, 10 parts of KH550 silane coupling agent, 2 parts of polyvinyl alcohol, 3 parts of dibutyl phthalate, 0.01 part of 200-mesh mesoporous material, and 5 parts of water, and mix them evenly to prepare a mesoporous material composite Insulation adhesive.

[0015] Cut the 10mm thick glass fiber mat into two pieces of 300*300mm size, stack them together, and test the thermal conductivity on the German NETZSCH thermal conductivity tester, which is 0.03402W / (m.k).

[0016] Coat the prepared composite thermal insulation adhesive on one of the glass fiber mats, attach the two glass fiber mats, and dry at 105°C. The thermal conductivity was measured to be 0.03761 W / (m.k).

Embodiment 2

[0018] Take 50 parts of water-based polyurethane, 5 parts of KH550 silane coupling agent, 2 parts of polyvinyl alcohol, 3 parts of dibutyl phthalate, 30 parts of 200-mesh mesoporous material, and 10 parts of water, and mix them evenly to prepare a composite mesoporous material. Insulation adhesive.

[0019] Cut the 10mm thick glass fiber mat into two pieces of 300*300mm size, stack them together, and test the thermal conductivity on the German NETZSCH thermal conductivity tester, which is 0.03402W / (m.k).

[0020] Coat the prepared composite thermal insulation adhesive on one of the glass fiber mats, attach the two glass fiber mats, and dry at 105°C. The thermal conductivity was measured to be 0.03282 W / (m.k).

Embodiment 3

[0022] Take 60 parts of water-based polyurethane, 1 part of KH550 silane coupling agent, 1 part of polyvinyl alcohol, 3 parts of dibutyl phthalate, 30 parts of 200-mesh mesoporous material, and 10 parts of water, and mix them evenly to prepare a composite mesoporous material. Insulation adhesive.

[0023] Cut the 10mm thick glass fiber mat into two pieces of 300*300mm size, stack them together, and test the thermal conductivity on the German NETZSCH thermal conductivity tester, which is 0.03388W / (m.k).

[0024] Coat the prepared composite thermal insulation adhesive on one of the glass fiber mats, attach the two glass fiber mats, and dry at 105°C. The thermal conductivity was measured to be 0.03276 W / (m.k).

[0025] The mesoporous material can also be directly compounded with various finished adhesives, which can improve the thermal insulation effect of the adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap