Device and method for preparing nanocrystalline structure of Al-Cu-Mg alloy

A technology of alloy nanocrystals, al-cu-mg, applied in the field of metal material processing, to achieve the effect of uniform grain structure, promoting recrystallization, promoting uniformity and refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

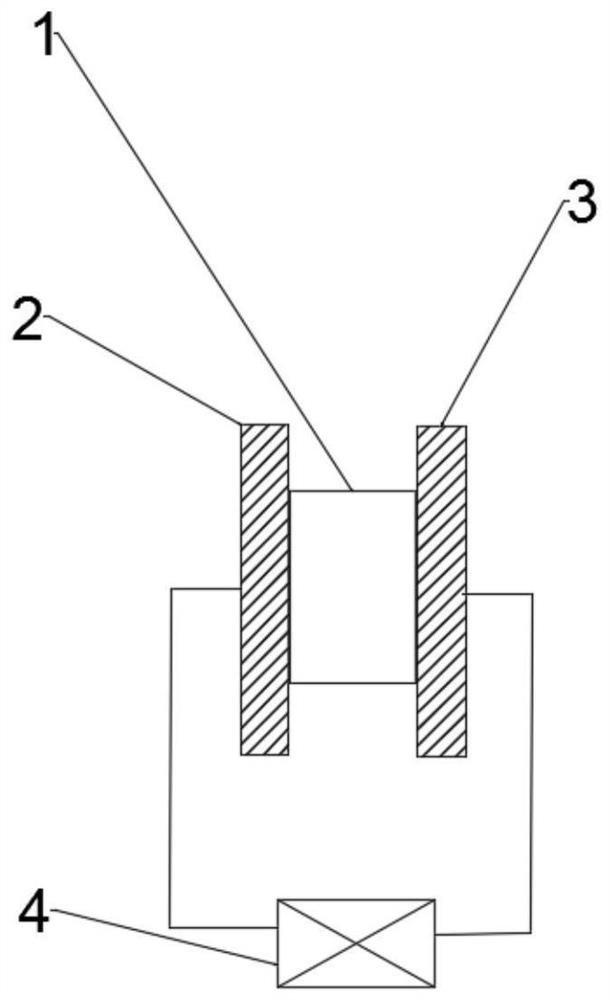

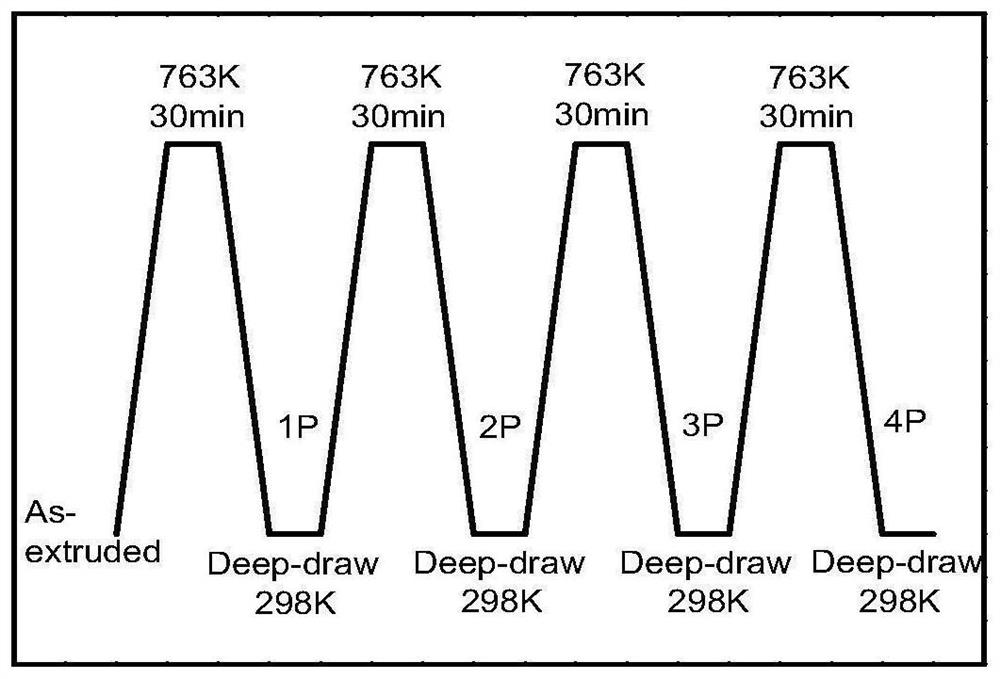

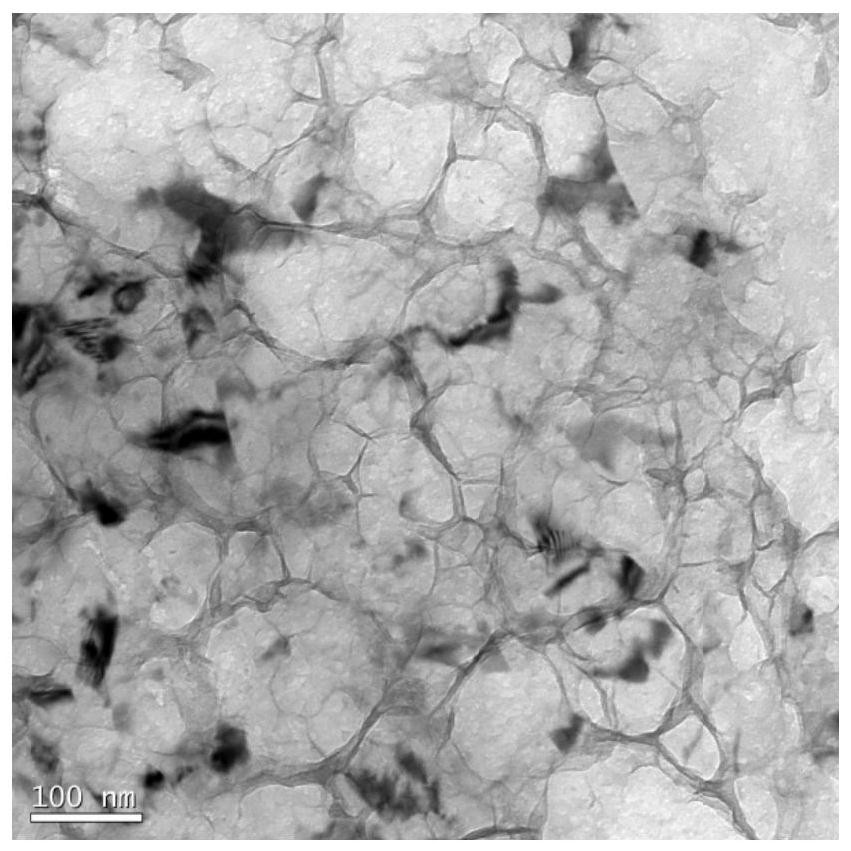

[0034] This embodiment provides a method for preparing Al-Cu-Mg alloy nano grain structure, the elemental composition of Al-Cu-Mg alloy in this embodiment is: Cu: 4.51wt.%, Mg: 1.46wt.%, Mn : 0.56wt.%, Si: 0.02wt.%, Fe: 0.01wt.%, the balance Al; the preparation method of the alloy is as follows: take pure aluminum with a purity of 99.98% and place it in a graphite crucible melting furnace, at 840 ° C , heated until all become molten; add the master alloy in sequence, lower the temperature to 720°C, stir thoroughly, and let it stand for 15-25 minutes; 30min; add the slagging agent to the surface of the molten aluminum, the slagging agent used in this embodiment is JY-D1, added at 0.1% to 0.2% of the aluminum alloy melt, the main components are chloride salts and fluorine salts, After standing still for 15-25 minutes, the slag is removed to obtain the alloy melt; the alloy melt is spray-formed with aluminum alloy spray-forming equipment, the pressure of the nitrogen gas is 1.0-2...

Embodiment 2

[0038] Referring to Example 1, this example provides a method for preparing Al-Cu-Mg alloy nanograin structure. The difference from Example 1 is that this example adopts four-pass recrystallization annealing process and four-pass high-speed The above-mentioned Al-Cu-Mg alloy materials were treated alternately by shearing process to prepare nano-grain structure; the temperature of the first recrystallization annealing process was 800K, the heating rate was 620K / min, and the holding time was 20min. The shear rate of the shear plate in the first high-speed shearing process is 95mm / s; the temperature of the second recrystallization annealing process is 800K, the heating rate is 620K / min, and the holding time is 20min. In the first high-speed shearing process, the shear rate of the shear plate was 90mm / s; the temperature of the third recrystallization annealing process was 800K, the heating rate was 620K / min, and the holding time was 20min. The shear rate of the shear plate in the hi...

Embodiment 3

[0040] Referring to Example 1, this example provides a method for preparing Al-Cu-Mg alloy nanograin structure. The difference from Example 1 is that this example adopts four-pass recrystallization annealing process and four-pass high-speed The above-mentioned Al-Cu-Mg alloy materials were treated alternately by shearing process to prepare nano-grain structure; the temperature of the first recrystallization annealing process was 750K, the heating rate was 640K / min, and the holding time was 40min. The shear rate of the shear plate in the first high-speed shearing process is 98mm / s; the temperature of the second recrystallization annealing process is 750K, the heating rate is 640K / min, and the holding time is 40min. In the first high-speed shearing process, the shear rate of the shear plate was 95mm / s; the temperature of the third recrystallization annealing process was 750K, the heating rate was 640K / min, and the holding time was 40min. During the high-speed shearing process, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com