High-density spherical particle composite weighting agent for well drilling or well cementation as well as preparation method of high-density spherical particle composite weighting agent

A technology of spherical particles and weighting agents, applied in wellbore/well components, drilling compositions, chemical instruments and methods, etc., can solve the problems of poor rheology of drilling fluid and increased drilling difficulty, and achieve acid tolerance Good, good fluidity, low bleeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

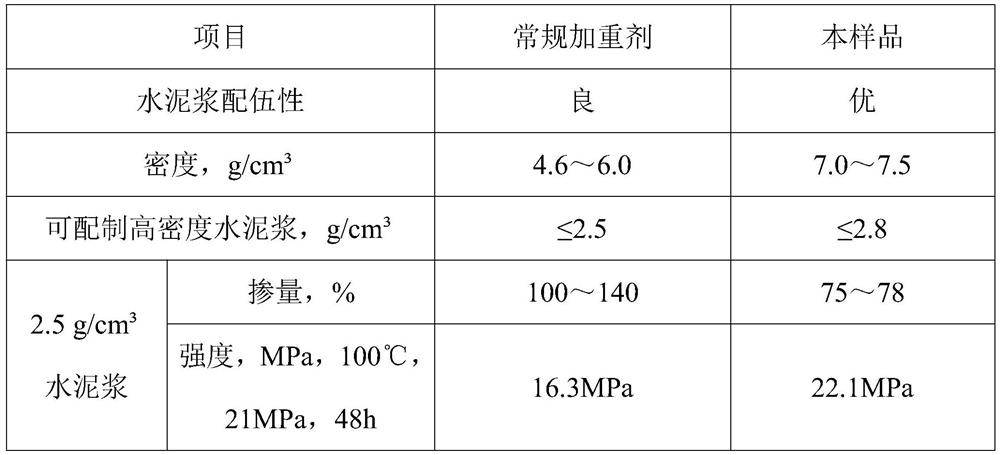

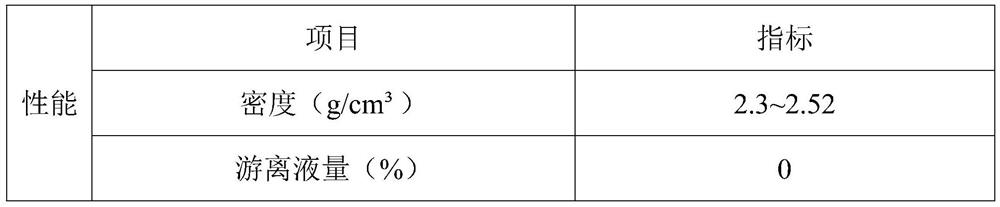

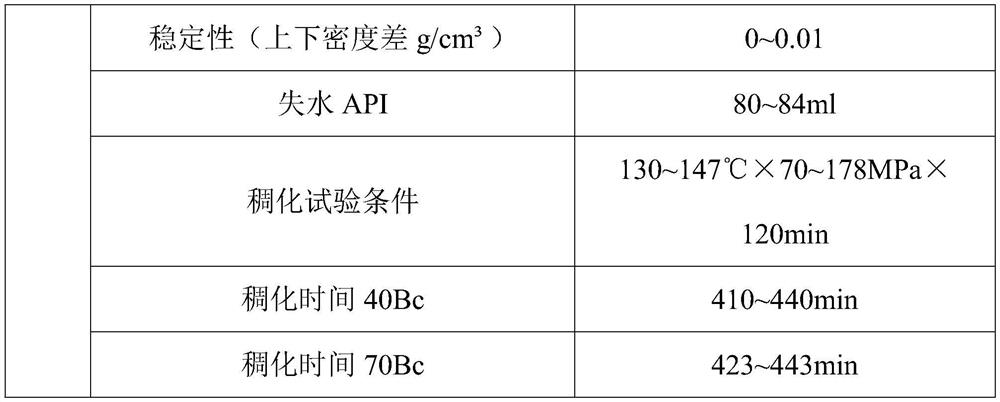

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments.

[0024] Prepare spherical particle composite weighting agent according to the process as follows:

[0025] 1) Selection of raw materials: low-carbon steel alloys are used as raw materials, and the composition of raw materials is analyzed and determined;

[0026] 2) Raw material selection and impurity removal: use magnetic separation method and sedimentation static method to remove dust, sand and impurities;

[0027] 3) Oxidation-reduction impurity removal: oxidation-reduction at 700-900°C removes various harmful impurities, removes oil stains or other volatile and decomposed organic minerals in raw materials at high temperature, and oxidizes and removes sulfur, phosphorus, silicon, and magnesium in raw materials and other impurities, liquid ammonia removes excess oxygen and carbon in the raw materials; after the above three steps, further detection and analysis of the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com