Method for estimating the deformability of metal material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

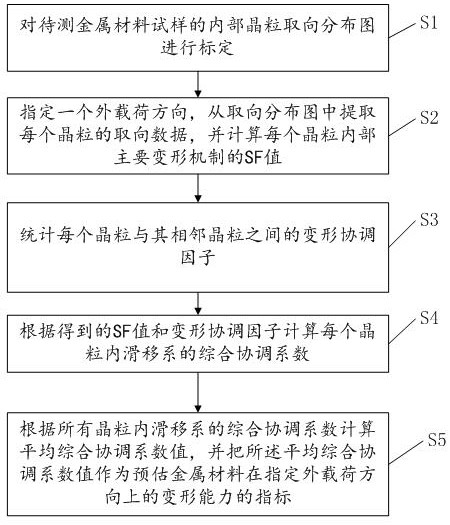

Method used

Image

Examples

Embodiment 1

[0090] The metal material sample to be tested in this embodiment is a rolled AZ31 magnesium alloy plate.

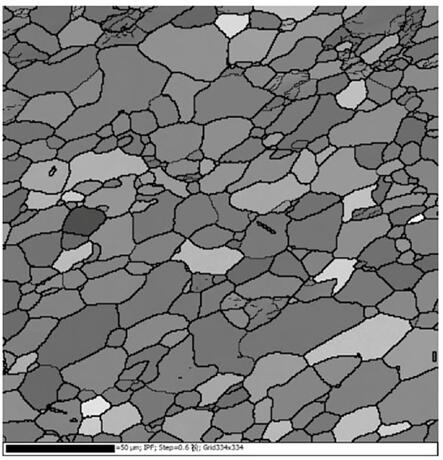

[0091] The grain orientation distribution diagram obtained by calibration in step S1 is shown in figure 2 , it can be seen from the figure that most of the grains in the plate show the same color, that is, the orientation of the internal grains tends to be preferred, which is a typical basal texture orientation phenomenon of magnesium alloys.

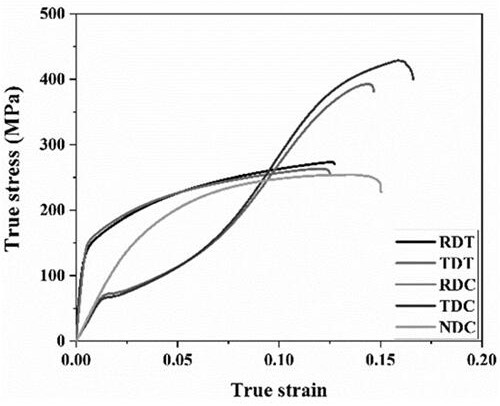

[0092] image 3 is the true stress-strain curve of the sample obtained through experiments, where RDT is the tensile true stress-strain curve along the rolling direction, RDC is the compressive true stress-strain curve along the rolling direction, and TDT is the tensile true stress-strain curve along the width direction True stress-strain curve, TDC is the compressive true stress-strain curve along the width direction, and NDC is the compressive true stress-strain curve along the thickness direction; this figure shows that the dena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com