VOCs waste gas treatment system

一种废气处理、废气的技术,应用在气体处理、膜技术、弥散粒子分离等方向,能够解决运行成本高、去除率地下、实用性降低等问题,达到运行成本低、高效利用、装置简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Sampling and analysis of VOCs exhaust gas from a factory, its specific properties are as follows:

[0035] Among them, in the exhaust gas: benzene 106.3mg / m³; toluene 287.5mg / m³; xylene 627.5mg / m³.

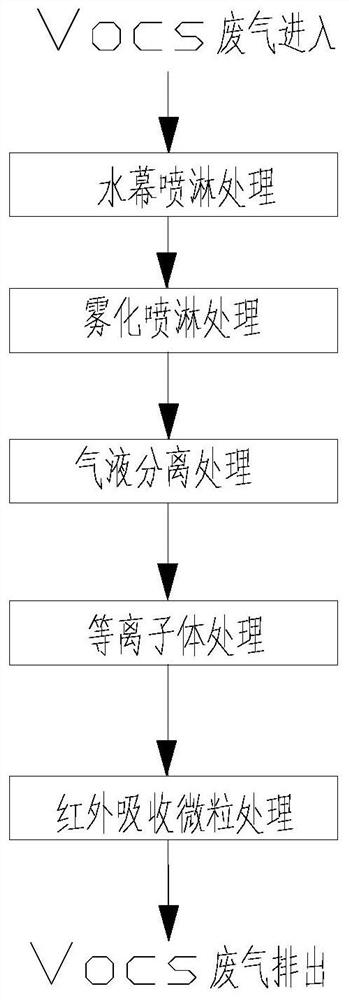

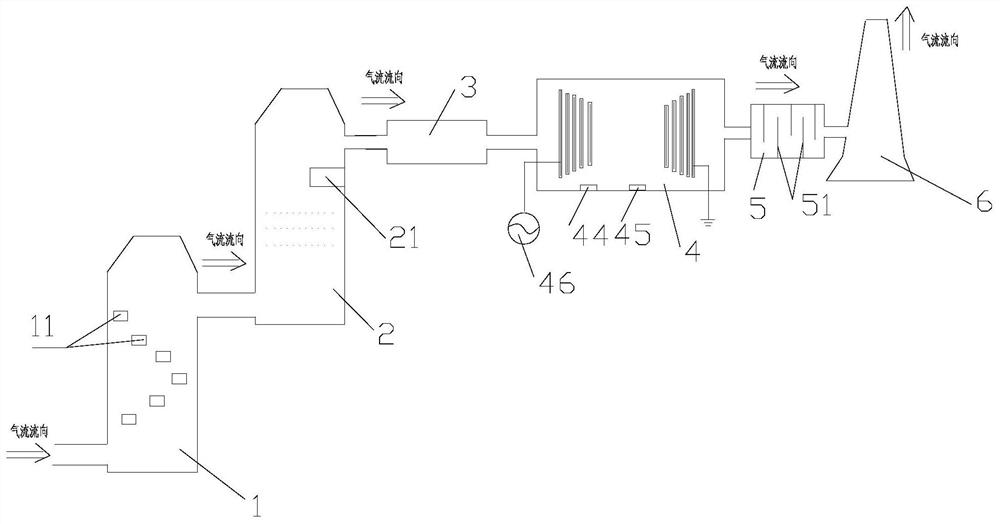

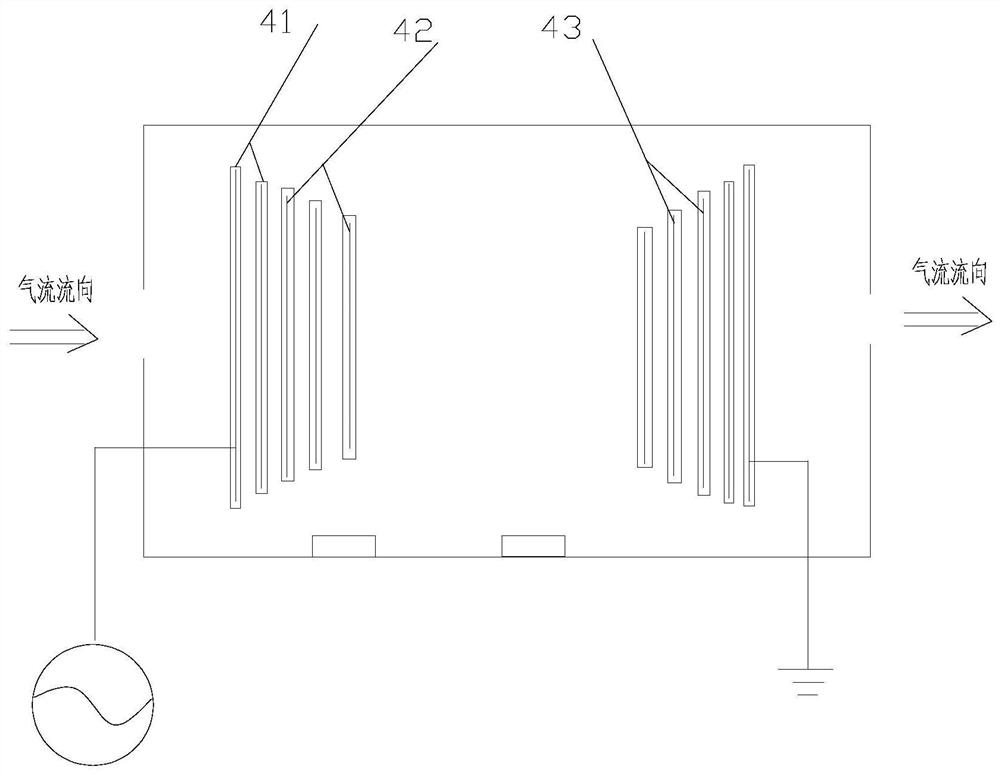

[0036] like Figure 1-4 As shown, the present embodiment provides a VOCs waste gas treatment method, comprising the following steps:

[0037] 1) Water curtain spray treatment

[0038] The VOCs waste gas is introduced from the bottom of the water curtain spray tower 1, and flows out from the upper part after being sprayed by the water curtain. The water curtain spray treatment method adopts annular spray, and the annular spray includes a plurality of spray parts 11, A plurality of the spray parts 11 are distributed in a spiral shape in the water curtain spray tower 1;

[0039] 2) Atomization spray treatment

[0040] Wherein, the spray liquid includes water liquid, and the water liquid is atomized by the atomizer 21 to form layers of water films, and the water films are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com