Method for producing potassium phosphate from phosphoric acid and potassium chloride

A technology of potassium phosphate and potassium chloride, which is applied in the field of phosphorus chemical industry, can solve problems such as incomplete removal of chloride ions, and achieve the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

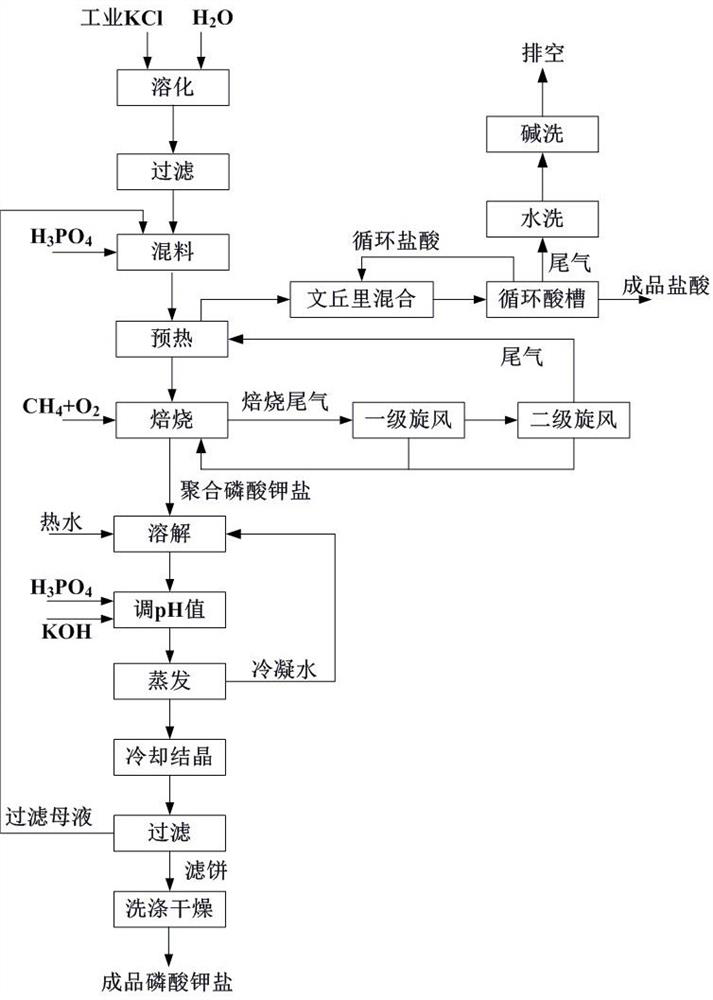

Image

Examples

Embodiment 1

[0014] Example 1: Add 100kg of industrial potassium chloride (98.28% KCl content) and 350kg of water produced by a mining company in Qinghai into a raw material dissolving tank, raise the temperature to 85°C and stir for 1 hour to completely dissolve potassium chloride, and separate it by filtration After removing the insoluble matter, transfer the potassium chloride solution into the mixing tank, and weigh 155kg of thermal phosphoric acid (H 3 PO 4 Content 85%) into the mixing tank, keep the temperature not lower than 80 ℃ and stir for 2 hours. At the same time, open the natural gas and air valves of the hot blast stove, and gradually open and adjust the natural gas and air valves after confirming that the ignition is successful, so that the temperature of the hot air entering the roaster from the hot blast stove is 550~600°C.

[0015] Mix the phosphoric acid and potassium chloride mixture evenly and transfer it to the preheater, heat it with the exhaust gas of the roaster t...

Embodiment 2

[0016] Example 2: Add 100kg of industrial potassium chloride (KCl content 98.46%) imported from Canada and 350kg of water into the raw material dissolving tank, raise the temperature to 85°C and stir for 1 hour to completely dissolve potassium chloride, and filter and separate the insoluble matter therein Finally, potassium chloride solution is transferred in the mixing tank, and 94kg thermal phosphoric acid (H 3 PO 4 Content 85%) into the mixing tank, keep the temperature not lower than 80 ℃ and stir for 2 hours. At the same time, open the natural gas and air valves of the hot blast stove, and gradually open and adjust the natural gas and air valves after confirming that the ignition is successful, so that the temperature of the hot air entering the roaster from the hot blast stove is 450~500°C.

[0017] Mix the phosphoric acid and potassium chloride mixture evenly and transfer it to the preheater, heat it with the exhaust gas of the roaster to above 120°C, and then inject i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap