Water-based sponge spray adhesive as well as preparation method and application thereof

A water-based, sponge technology, used in adhesives, adhesive types, adhesive additives, etc., can solve the problems of complex preparation, unsuitable for wide application, etc., and achieve the effects of simple preparation method, broad market application prospects, and low raw material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In this example, the water-based environmentally friendly spray glue is prepared through the following steps.

[0043] (1) the tapioca dextrin of quality 0.3kg is dissolved in 0.7kg water, adds 0.05kg graphene, is warming up to 90 ℃, stirs through 30min, obtains solution A;

[0044] (2) cooling the solution A obtained in step (1) to 30° C., adding 7g sodium benzoate, and 4.0g chitin, and stirring for 10min to obtain starch solution B;

[0045] (3) 0.25kg of neoprene emulsion was added to the solution B obtained in step (2), and stirred for 20min to obtain water-based sponge spray glue.

Embodiment 2

[0047]In this example, the water-based environmentally friendly spray glue is prepared through the following steps.

[0048] (1) the cornstarch of quality 0.2kg is dissolved in 0.8kg water, adds 0.1kg graphene, is warming up to 95 ℃, stirs through 50min, obtains solution A;

[0049] (2) cooling the solution A obtained in the step (1) to 40° C., adding 10 g of sodium benzoate, and 8.0 g of chitin, and stirring for 25 min to obtain a starch solution B;

[0050] (3) Add 0.75kg of neoprene emulsion to the solution B obtained in step (2), and stir to obtain water-based sponge spray glue for 30min.

Embodiment 3

[0052] In this example, the water-based environmentally friendly spray glue is prepared through the following steps.

[0053] (1) the potato starch of quality 0.4kg is dissolved in 0.6kg water, adds 0.08kg graphene, is warming up to 80 ℃, stirs through 15min, obtains solution A;

[0054] (2) cooling the solution A obtained in the step (1) to 20° C., adding 5g sodium benzoate, and 5g chitin, and stirring for 5min to obtain starch solution B;

[0055] (3) Add 0.3 kg of neoprene emulsion to the solution B obtained in step (2), and stir to obtain water-based sponge spray glue for 10 min.

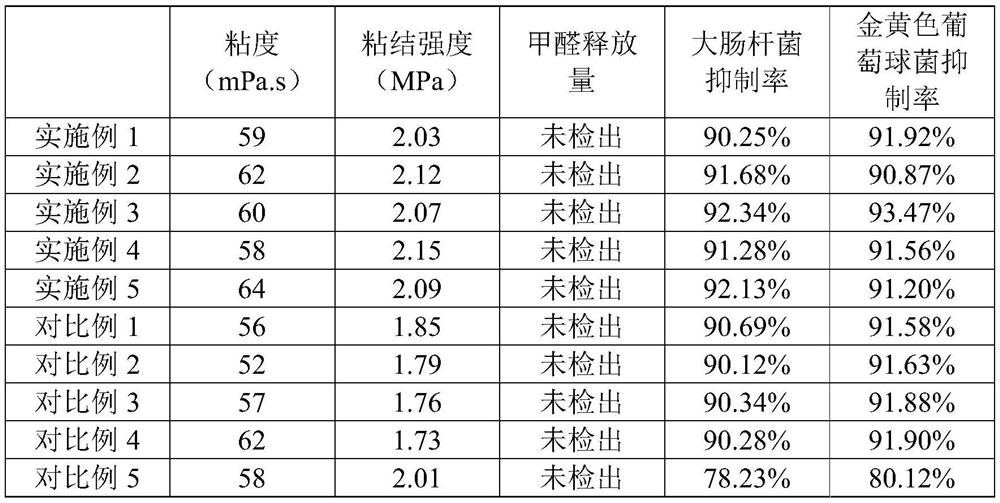

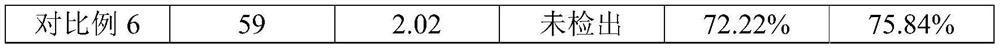

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap