Thermal performance assessment test correction calculation method for steam turbine with low-temperature economizer

A steam turbine performance test procedure and low-temperature economizer technology, applied in calculation, design optimization/simulation, computer-aided design, etc. Problems such as water flow and heat absorption are the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

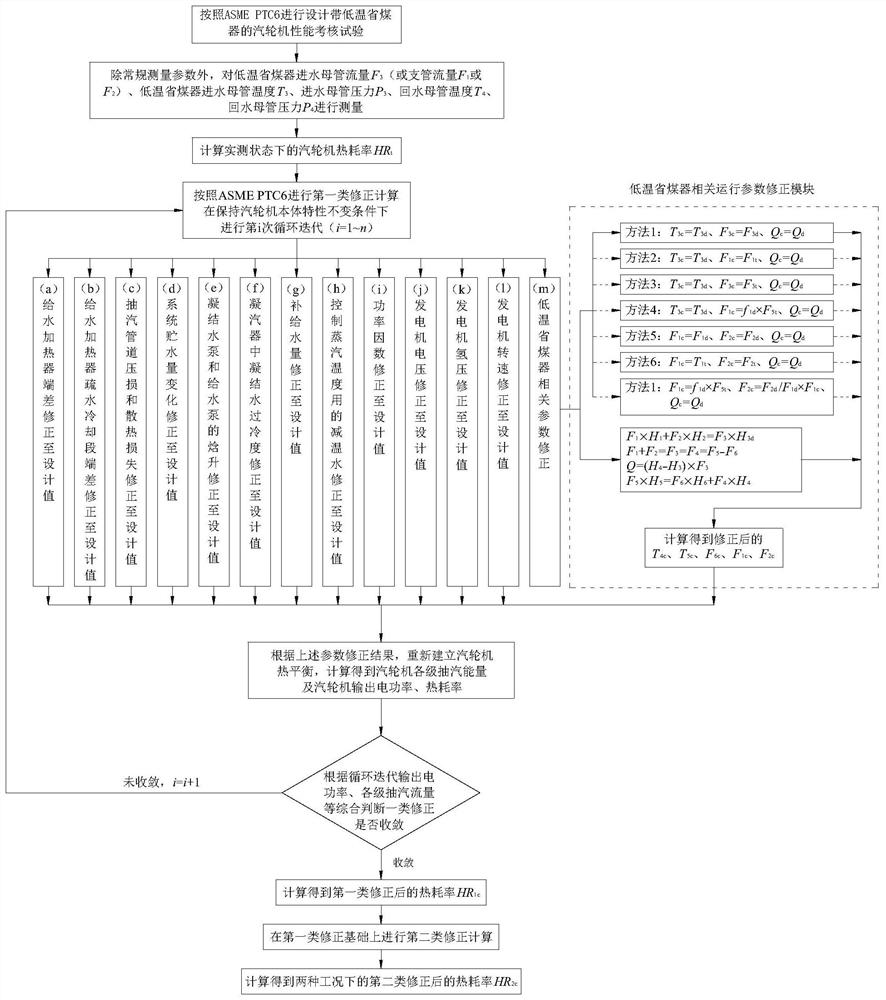

[0064] A further detailed description of the correction calculation method for the thermal performance assessment test of a steam turbine with a low-temperature economizer designed according to the present invention will be given below in conjunction with the accompanying drawings and examples.

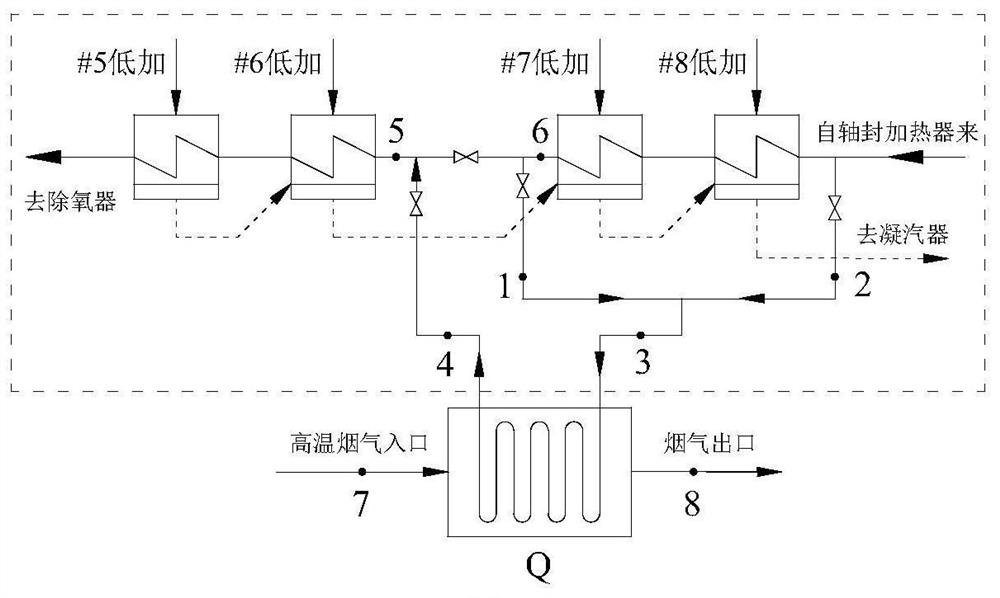

[0065] attached figure 1 It is a typical thermal system diagram of the low-pressure heater of a steam turbine designed with a low-temperature economizer. The thermal system of the low-pressure heater of the steam turbine includes a total of 4 low-pressure heaters, numbered #5, #6, #7, and #8. Condensed water from the shaft seal heater passes through #8 LP, #7 LP, #6 LP and #5 LP respectively, and finally flows to the deaerator. The low-pressure heater steam drains from #5 to #8 and flows gradually, and finally flows to the condenser. The low-temperature economizer has two water supply sources. The low-temperature water source takes water from the #8 low-fill inlet, and the high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com