Electrostatic adsorption particle catcher with external insulated electrode

A particle trap, electrostatic adsorption technology, applied in the field of exhaust gas post-treatment and air purification, can solve problems such as creepage, difficult disassembly and cleaning, damage to high-voltage insulation components, etc., to improve the capture effect, save labor costs, increase The effect of the attached area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

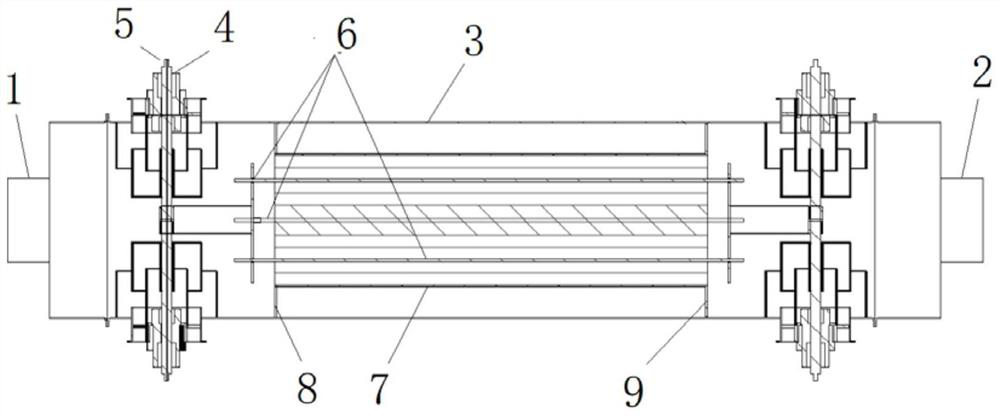

[0022] Referring to the accompanying drawings, the embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

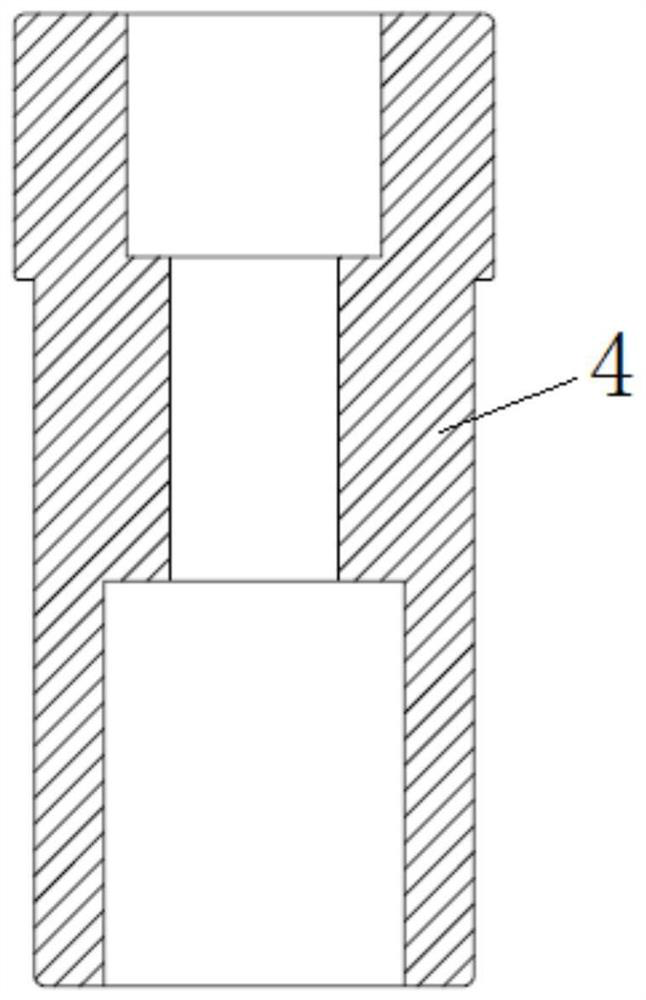

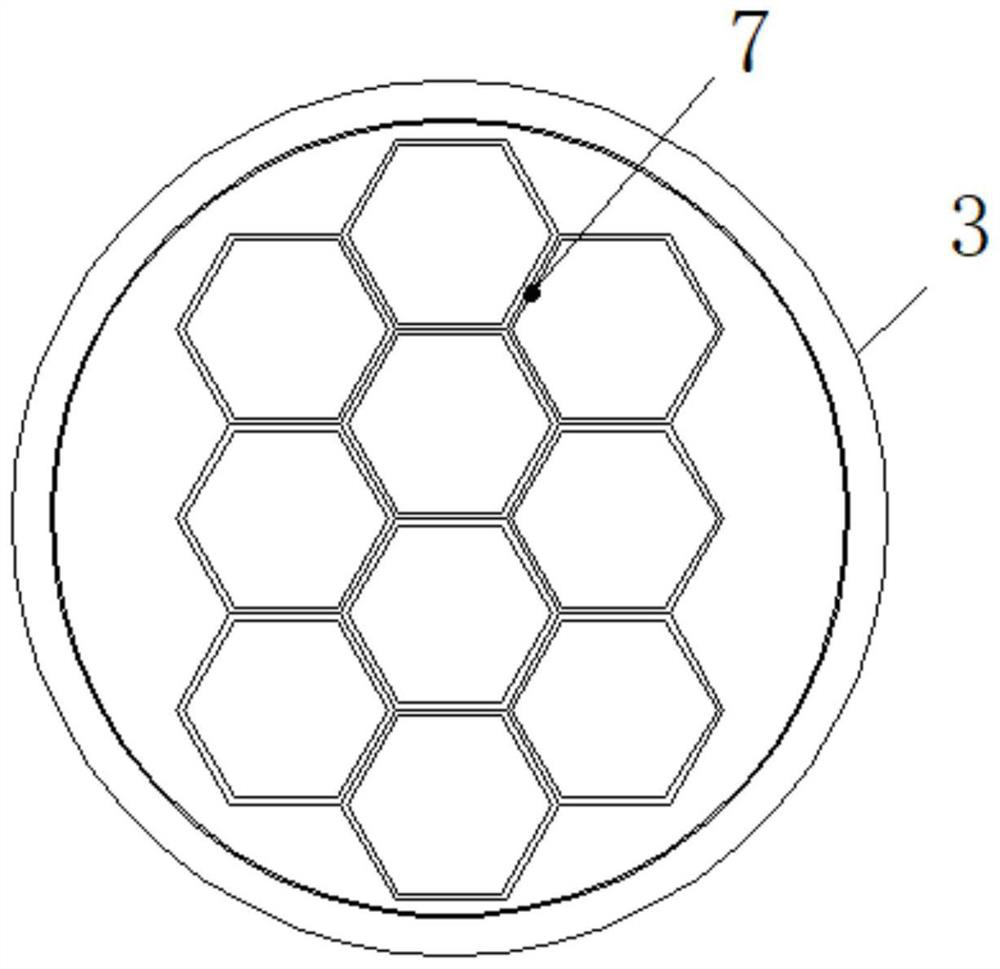

[0023] The electrode insulation external electrostatic adsorption particle collector includes a conductive dust collection tube 2, the two ends of the dust collection tube 2 are respectively equipped with an air inlet pipe 1 and an air outlet pipe 2, and the outer walls of the dust collection cylinder 3 are respectively installed with insulating supports at the inlet and outlet ends Part 4 also includes a high-voltage power supply terminal 5, the high-voltage power supply terminal 5 runs through the dust collection cylinder 3, the two ends of the high-voltage power supply terminal 5 pass through the insulating support 4 and are fixed by its support, the high-voltage power supply terminal 5 and the dust collection cylinder 3 Insulation without contact; corona wires 6 are electrically connected between the high-volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com