An electric field assisted titanium alloy micro-gear extrusion die and method thereof

An electric field-assisted extrusion molding technology, which is applied to metal extrusion dies and other directions, can solve problems such as short life, complex mold structure, and uneven density distribution of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

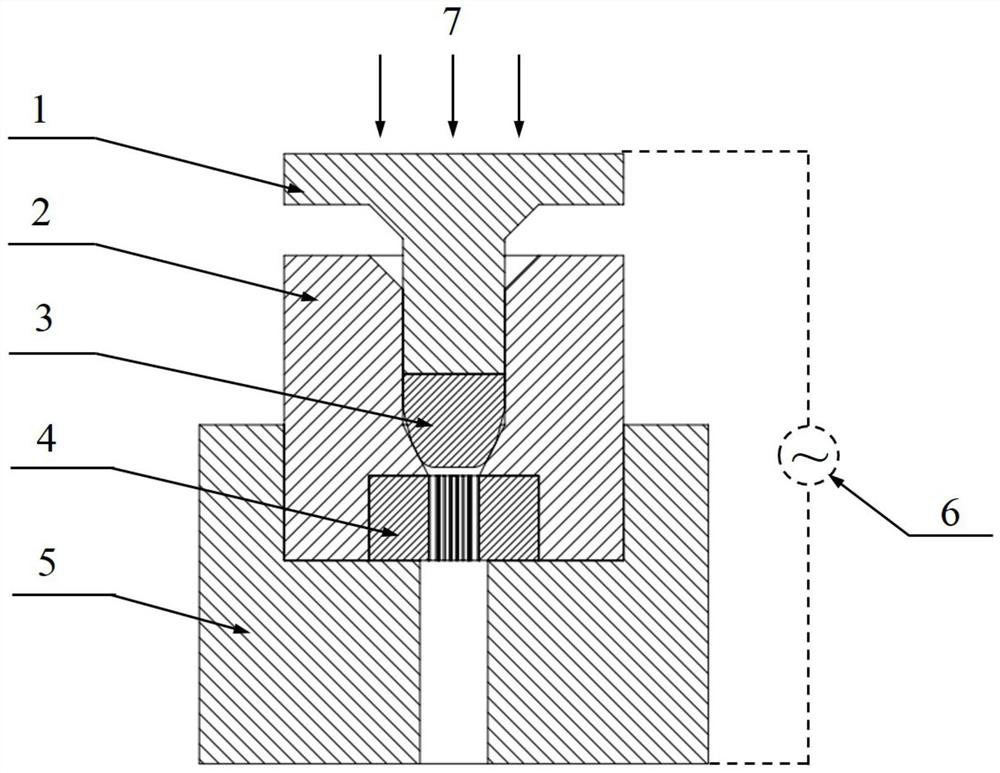

[0043] Embodiment 1, reference figure 1 , the electric field-assisted titanium alloy micro-gear extrusion molding die of this program includes a punch 1, an inner sleeve 2, a die 4 and a top die.

[0044] The upper end of the inner sleeve 2 is provided with a through hole for filling titanium alloy blanks. The conical surface at the upper end of the through hole matches the taper at the lower end of the punch 1; In the counterbore at the top of the top mold.

[0045] Among them, the punch 1 has a large chamfer at the sudden change in structure, which can enhance the strength of the punch 1 and reduce stress concentration.

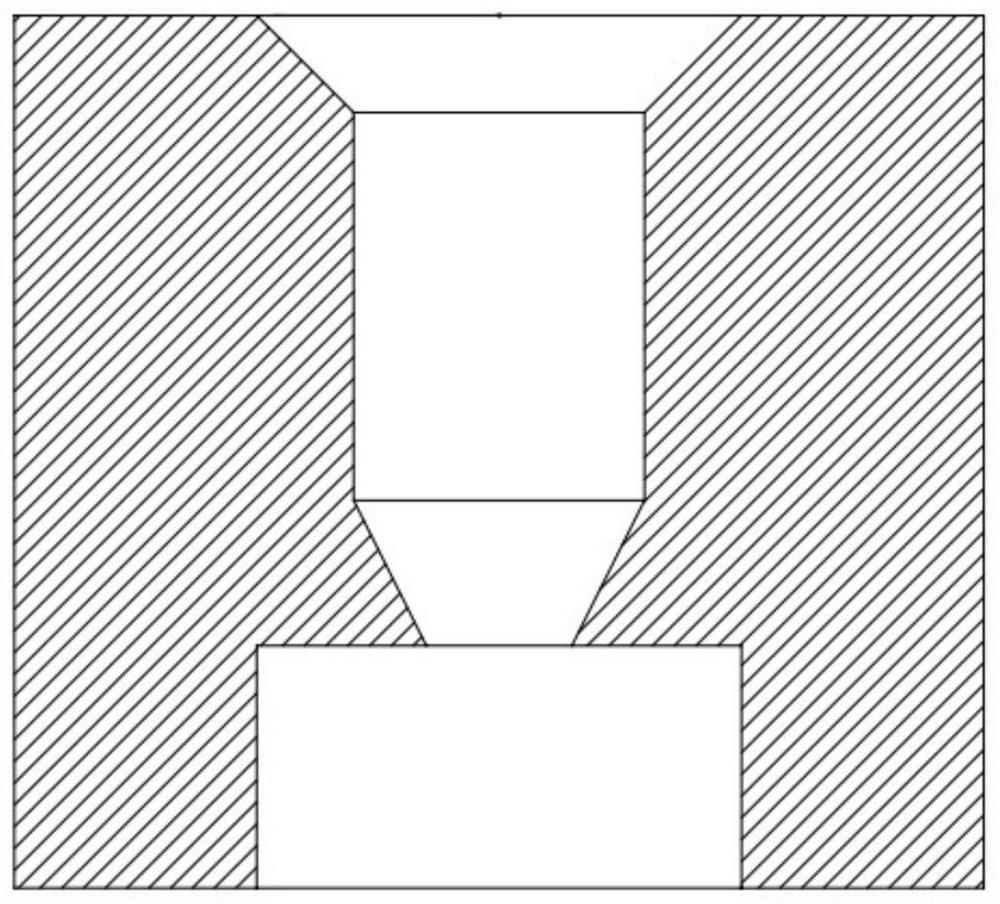

[0046] The large chamfer at the assembly end of the inner sleeve 2 and the punch 1 serves as a guiding structure, the lower end of the through hole where the inner sleeve 2 installs the titanium alloy blank 3 and the punch 1 is conical, and the other end is a counterbore structure.

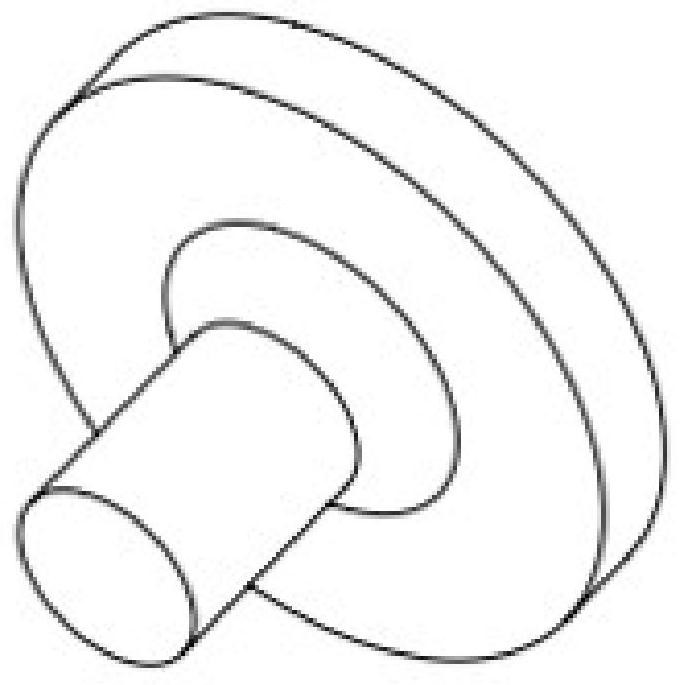

[0047] The cavity of die 4 is a through structure, and the modulus and ...

Embodiment 2

[0059] Embodiment 2, an electric field-assisted extrusion molding method of titanium alloy microgears, comprising:

[0060] S1. Under the pressure of 55MPa~70MPa, the titanium alloy billet is pre-extruded to reduce the porosity of the titanium alloy billet by 5%-9%, so as to increase the density of the original billet;

[0061] In traditional compression molding, whether it is one-way or two-way pressing, there will be uneven distribution of billet density and high residual porosity. However, the present invention adopts pre-extrusion before molding, and the relative density of the final formed microgear can be If it is increased by more than 10%, the porosity is relatively reduced by 7%.

[0062] S2. In a vacuum environment, at a heating rate of 25°C / s-40°C / s, heat the titanium alloy billet to 400°C-500°C, keep it warm for 0.5h, reduce the pressure to 0.01-0.03MPa, and degas the titanium alloy billet ;

[0063] Preheat the raw material of titanium alloy billet to reach a te...

Embodiment 3

[0075] Embodiment 3, verify the correctness of the process of the present invention:

[0076] S1. Pre-extruding the titanium alloy billet 3 under a pressure of 55MPa to 70MPa to reduce the porosity of the billet by 8%;

[0077] S2. In a vacuum environment, at a heating rate of 25°C / s-40°C / s, heat the titanium alloy blank 3 to 400°C-500°C, keep it warm for 0.5h, reduce the pressure to 0.01-0.03MPa, and carry out the titanium alloy blank 3 outgassing;

[0078] S3. Fill the titanium alloy blank 3 into the through hole of the inner sleeve 2, the punch 1 is assembled in the inner sleeve 2, the die 4 is assembled in the counterbore structure at the bottom of the inner sleeve 2, and then the inner sleeve 2 is assembled on the top In the counterbore structure at the upper end of the mold; then the mold containing the titanium alloy blank 3 is installed in the forming chamber;

[0079] S4. Install the mold containing the titanium alloy blank in a molding chamber with a vacuum degree ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com