Pulverized coal circulation pyrolysis reactor

A technology of pyrolysis reactor and pyrolysis reaction, which is applied in special forms of dry distillation, petroleum industry, coking oven, etc., and can solve the problems of secondary cracking of pyrolysis oil and gas, short residence time of pulverized coal, and low yield of pyrolysis products, etc. , to achieve the effect of reducing the residence time, weakening the secondary cracking reaction and rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0028] Example.

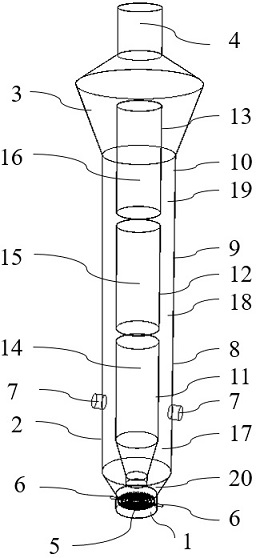

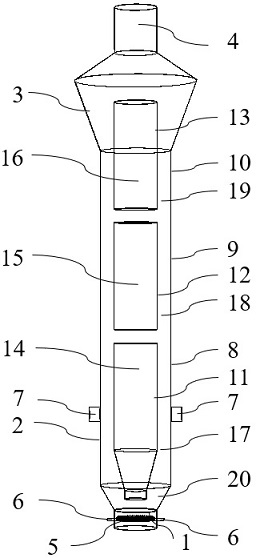

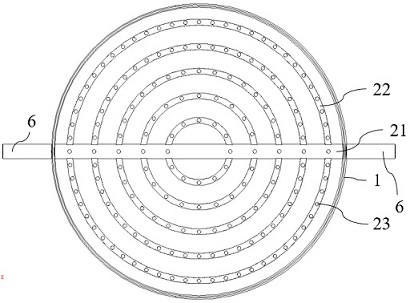

[0029] see Figure 1 to Figure 3 , in this embodiment, a pulverized coal circulating pyrolysis reactor, including a pyrolysis product delivery section 4, a reactant and product separation section 3, a circulating pyrolysis reaction section 2 and a heat carrier gas inlet arranged in sequence from top to bottom segment 1.

[0030]The pyrolysis product delivery section 4 is used to quickly lead the pyrolysis oil and gas products out of the pulverized coal pyrolysis reactor, and weaken the secondary cracking reaction of the pyrolysis oil and gas.

[0031] The reactant and product separation section 3 is used to reduce the superficial gas velocity, efficiently and quickly separate the pyrolysis produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com