Oil-gas separation type variable oil hole combined crash-resistant buffer

A separate buffer technology, applied in the direction of gas-hydraulic shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of poor flexibility, limited stroke, and the impact of the total energy absorption of the buffer, so as to improve the buffering efficiency , Improve the bearing capacity, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

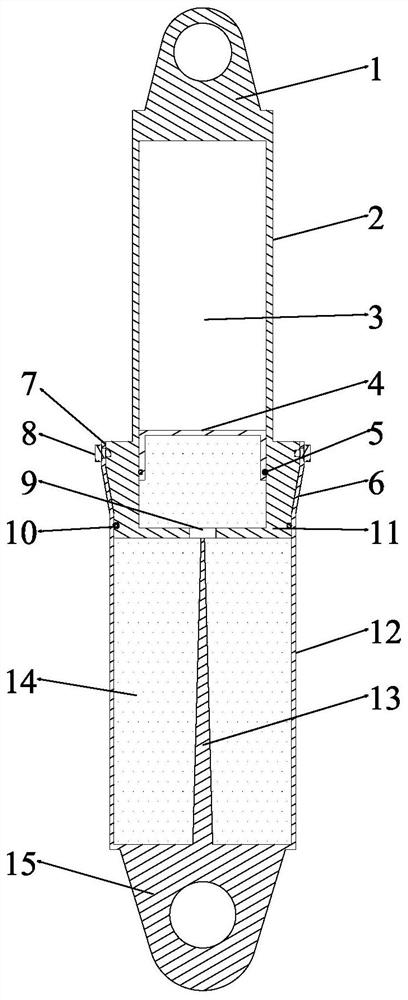

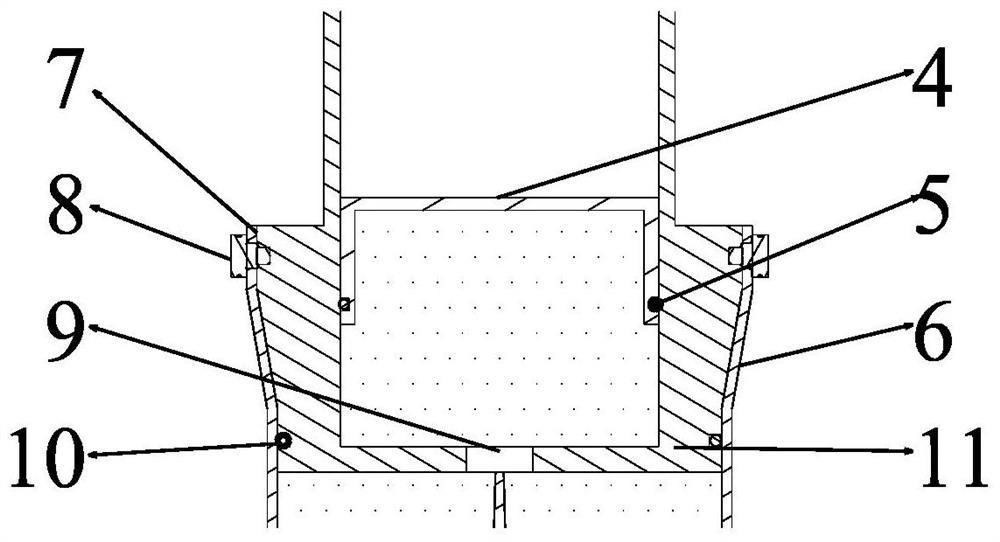

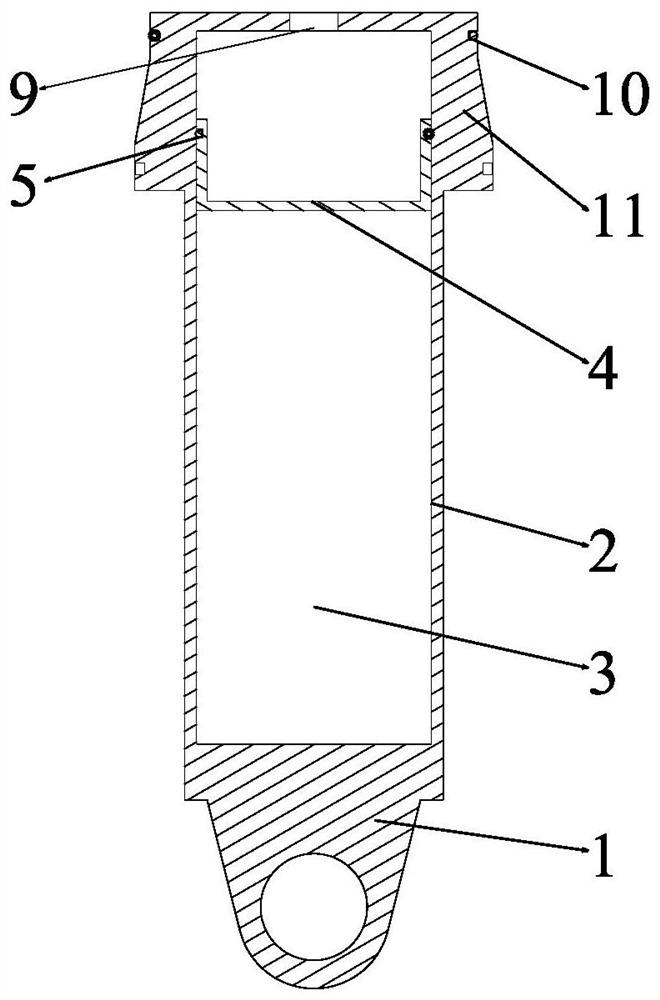

[0023] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] Such as Figure 1-3 As shown, the present invention has designed an oil-air separation type variable oil hole composite anti-crash buffer, including a piston rod assembly and a metal expansion cylinder. The piston rod assembly includes a piston rod 2 , a floating piston 4 and a conical head 11 . The lower end of the piston rod 2 is in contact with the cone head 11 and fixed by the screw 8. The space formed by the piston rod 2 and the cone head 11 is used as the air chamber 3. The floating piston 4 is placed in the air chamber 3 and can float up and down. The cone head There is an oil hole 9 at the center of the bottom of 11, and the oil hole 9 can be scaled according to the force. The metal expansion cylinder includes a sizing guide belt 7, a diameter reducing belt 6 and an expansion cylinder body 12, and the sizing guide belt 7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com