High-sensitivity AlN piezoelectric hydrophone and preparation method thereof

A high-sensitivity, hydrophone technology, applied in the direction of instruments, using electrical devices, using electromagnetic means, etc., can solve the problem of low sensitivity and achieve the effects of increased sensitivity, good practical application value, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

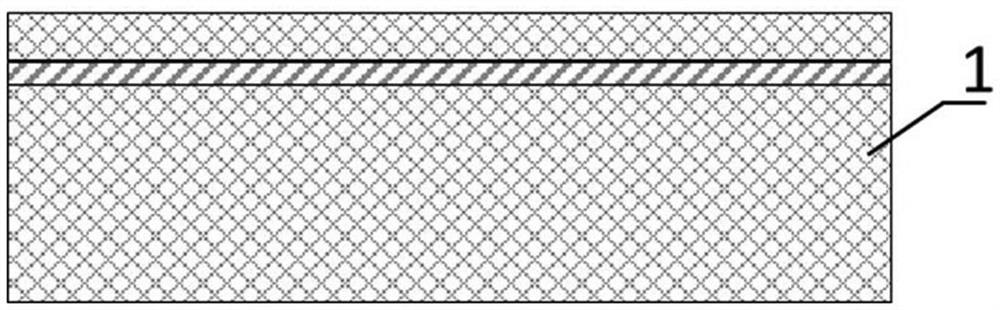

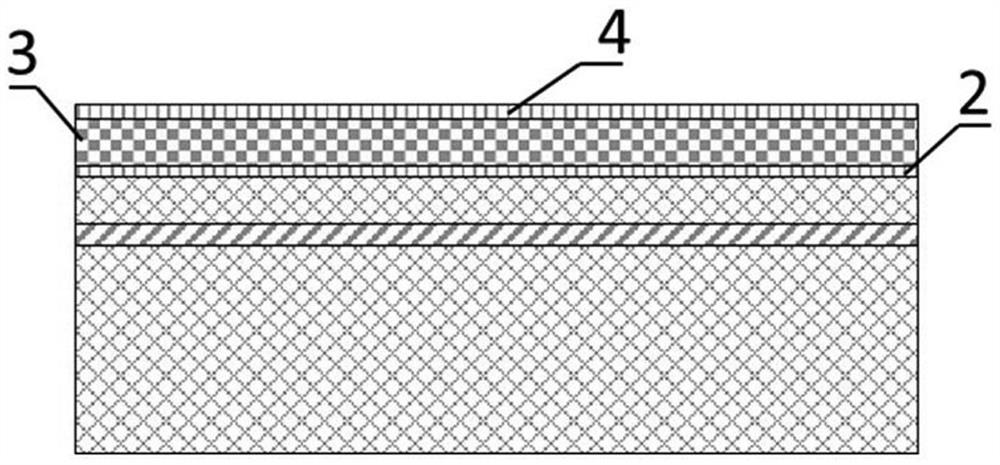

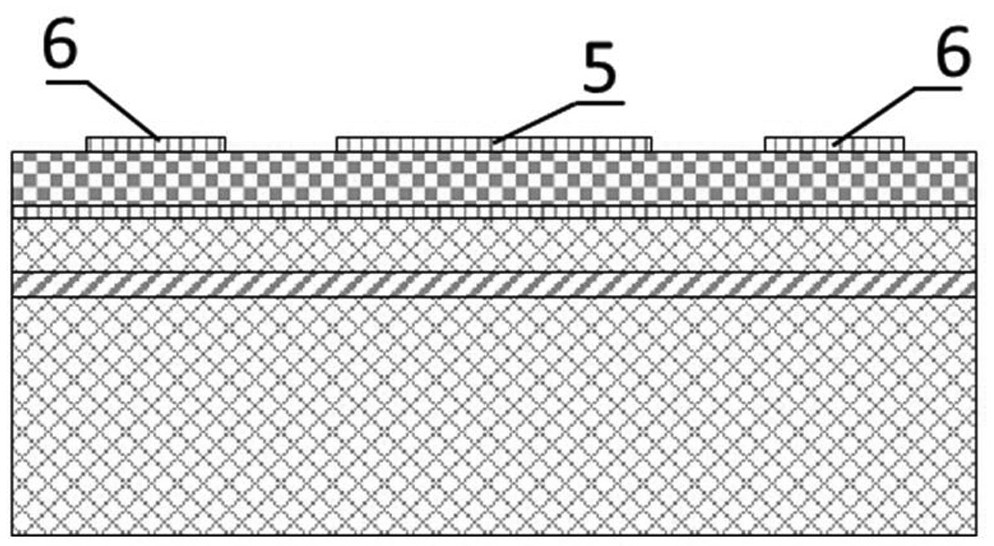

[0037] A high-sensitivity AlN piezoelectric hydrophone comprises an SOI substrate 1, a lower electrode layer 2, an AlN piezoelectric layer 3 and an upper electrode layer 4 are sequentially sputtered and deposited on the device silicon layer of the SOI substrate, and the upper electrode layer 4 is made of dry etched to form a patterned positive electrode 5 and a patterned negative electrode 6, and then use plasma-enhanced chemical vapor deposition to grow SiO 2 Protective layer 7, etch off the oxide layer on the patterned positive electrode 5 and the patterned negative electrode 6 afterwards, deposit the positive electrode pad 8 after metal stripping on the patterned positive electrode 5, in the pattern Deposit the metal-stripped negative electrode pad 9 on the negative electrode 6 after plating, etch the cavity 10 on the silicon substrate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com