Preparation method for potassium nitrate

A technology of potassium nitrate and nitrate, applied in directions such as the preparation of alkali metal nitrate, can solve the problems of high raw material cost, increased process cost, complicated process, etc., and achieves the effects of reducing process energy consumption, reducing preparation cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

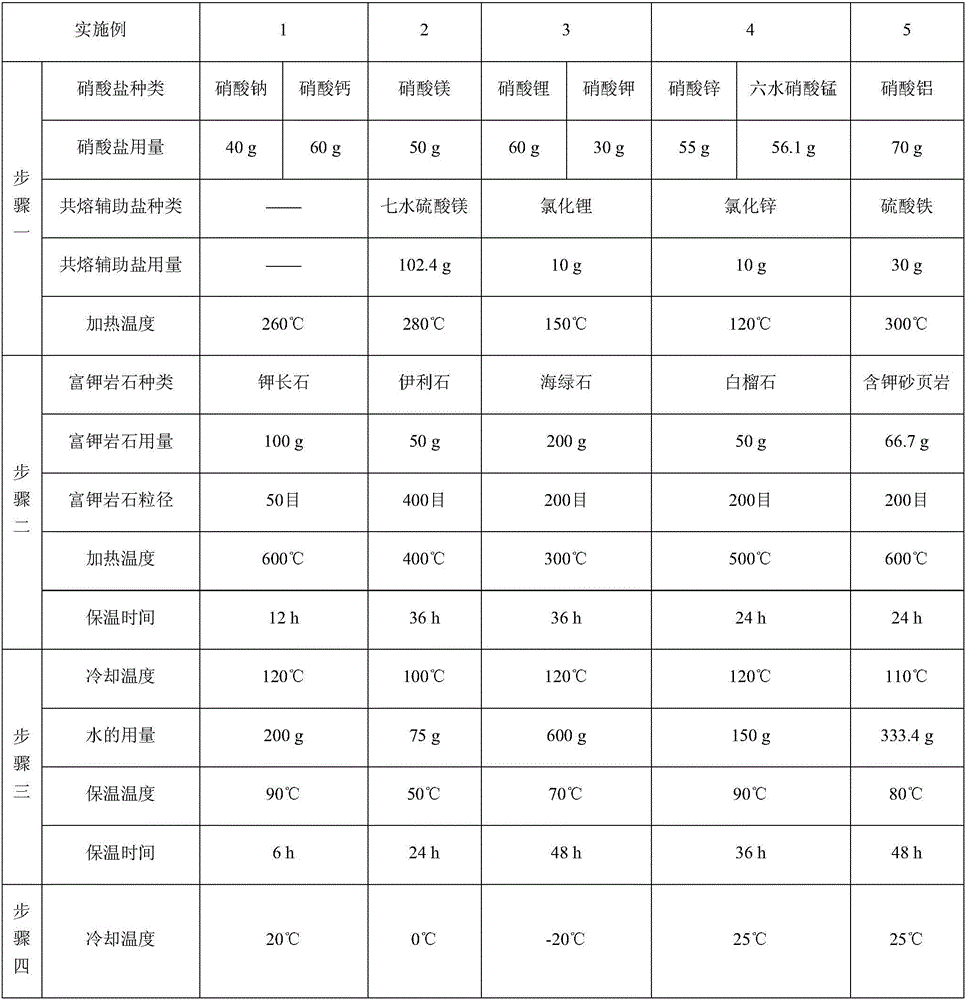

Examples

preparation example Construction

[0023] The preparation method of described a kind of potassium nitrate comprises the steps:

[0024] In the first step, the nitrate is heated to no more than 300° C. for melting to obtain a first melt.

[0025] Preferably, the eutectic auxiliary salt can be mixed with the nitrate, and then heated to no more than 300°C; wherein, the mass ratio of the nitrate to the eutectic auxiliary salt is not lower than 1:1.

[0026] Specifically, the nitrate is selected from sodium nitrate, potassium nitrate, lithium nitrate, magnesium nitrate, calcium nitrate, strontium nitrate, barium nitrate, lanthanum nitrate, cerium nitrate, manganese nitrate, niobium nitrate, iron nitrate, cobalt nitrate, nickel nitrate , copper nitrate, zinc nitrate, cadmium nitrate, aluminum nitrate, lead nitrate, bismuth nitrate, tin nitrate, gallium nitrate, molybdenum nitrate; preferably, the nitrate is selected from sodium nitrate, potassium nitrate, lithium nitrate, nitric acid At least one of magnesium, calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com