Thermotechnical design method suitable for sodium water once-through steam generator

A technology of steam generator and thermal engineering design, applied in the primary side of steam generator, computer-aided design, design optimization/simulation, etc., can solve problems such as only applicable, and achieve the effect of wide application and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, the present invention is described in further detail:

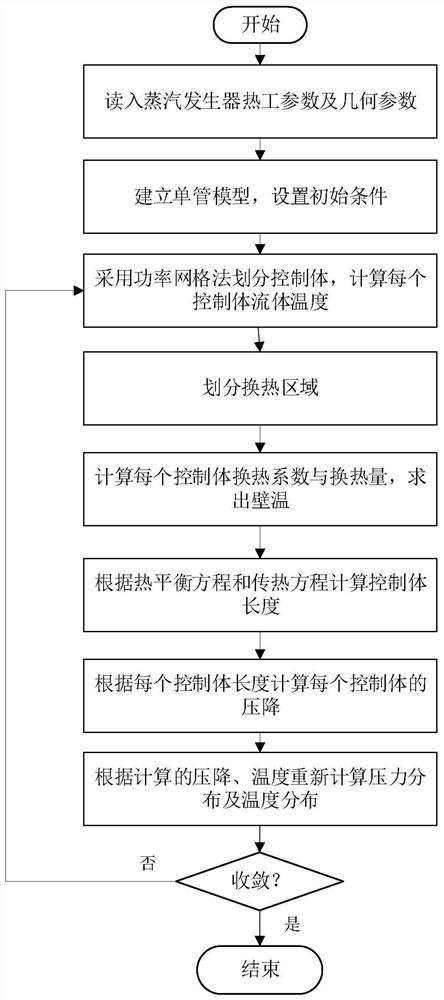

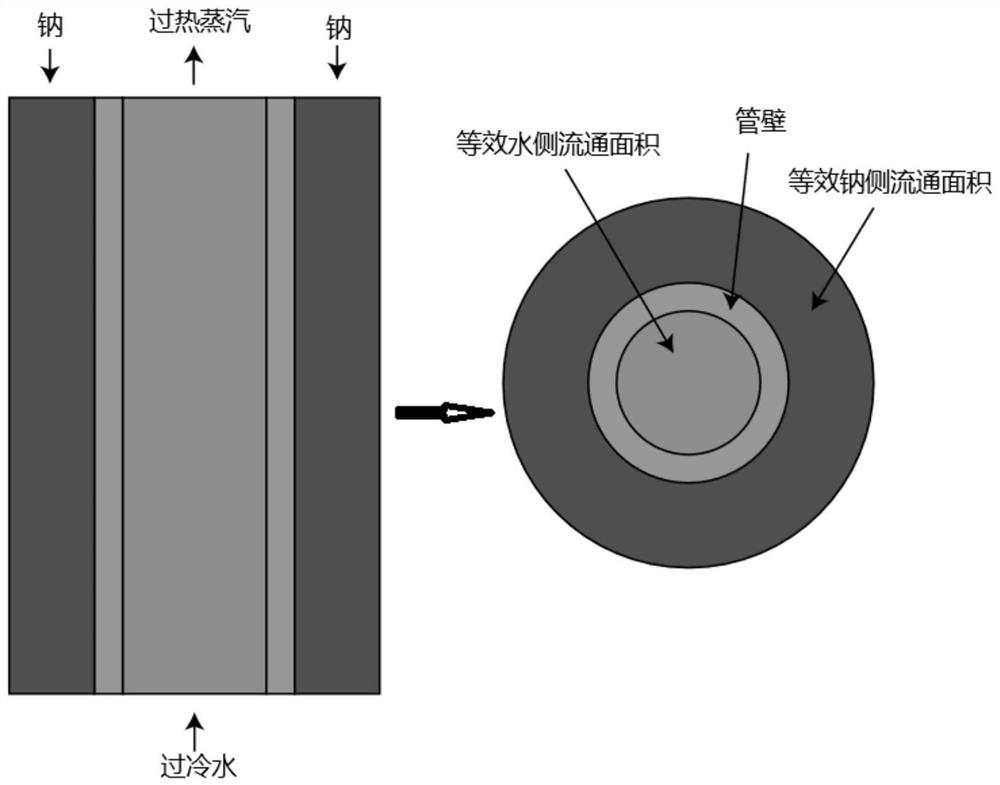

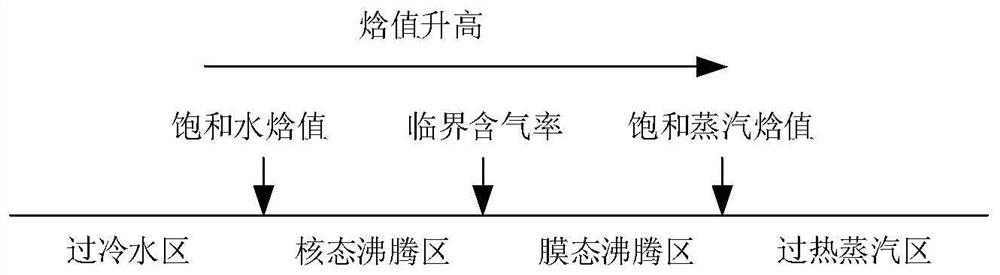

[0055] Such as figure 1 Shown, a kind of thermal engineering design method that the present invention is applicable to sodium-water once-through steam generator comprises the following steps:

[0056] Step 1: The input variables read include sodium-water direct-flow steam generator sodium-side outlet temperature and water-side inlet temperature, sodium-water direct-flow steam generator heat transfer power, sodium-side and water-side outlet pressure, sodium-water direct-flow steam generator transmission The inner diameter and outer diameter of the heat pipe, the number of heat transfer tubes, the number of control bodies along the length of the heat transfer tube of the sodium-water direct-flow steam generator, and the calculation accuracy.

[0057]The purpose of the thermal design calculation is to calculate the heat transfer area of the steam generator required un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com