Flexible lithium ion battery and preparation method thereof

A lithium-ion battery, flexible technology, applied in the direction of battery electrodes, secondary batteries, battery components, etc., can solve the problems of poor bending performance, low capacity of flexible lithium-ion batteries, etc., to relieve stress, improve electrochemical performance, Improved stability and security effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

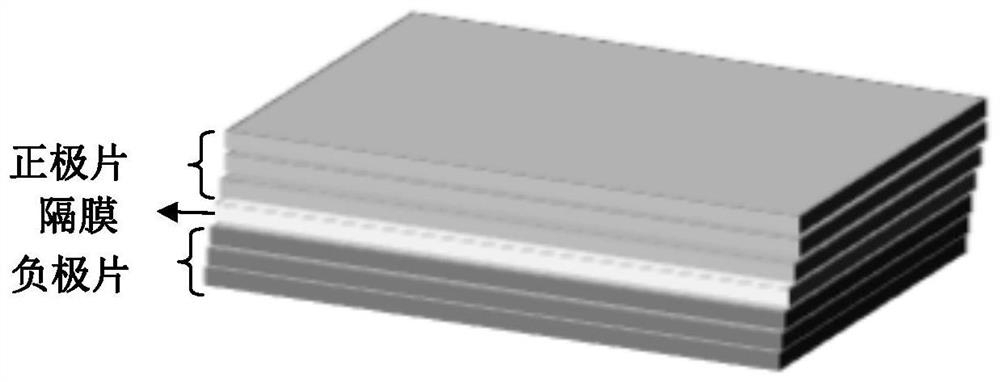

[0061] Accordingly, an embodiment of the present invention provides a method for preparing a flexible lithium-ion battery, including the following preparation steps:

[0062] S10. Obtain a positive electrode slurry comprising a positive electrode active material, a positive electrode binder, a positive electrode conductive agent, and a positive electrode solvent, deposit the positive electrode slurry on a substrate, and dry and separate to obtain a positive electrode film;

[0063] S20. Obtain a negative electrode slurry comprising a negative electrode active material, a negative electrode binder, a negative electrode conductive agent, and a negative electrode solvent, deposit the negative electrode slurry on a substrate, and dry and separate to obtain a negative electrode film;

[0064] S30. Laminating and pressing the multi-layer positive electrode film to obtain the positive electrode sheet;

[0065] S40. laminating and pressing the multi-layer negative electrode film to ob...

Embodiment 1

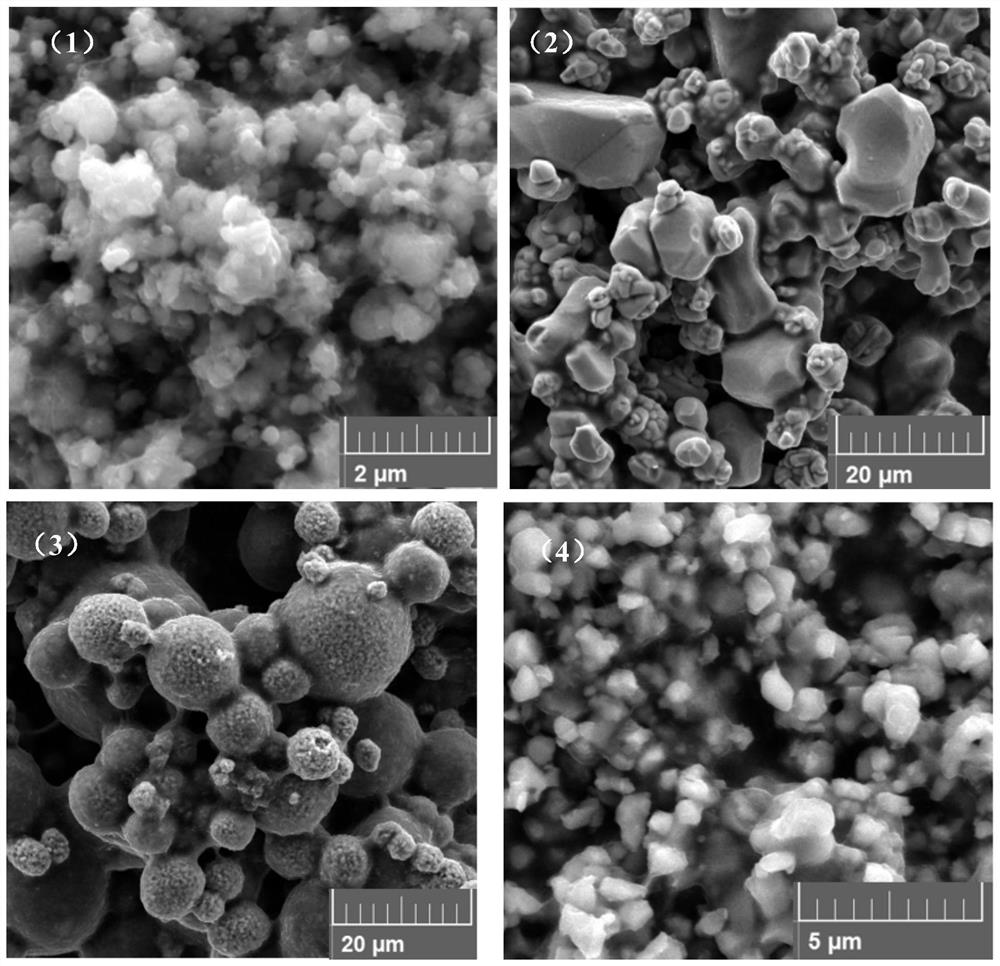

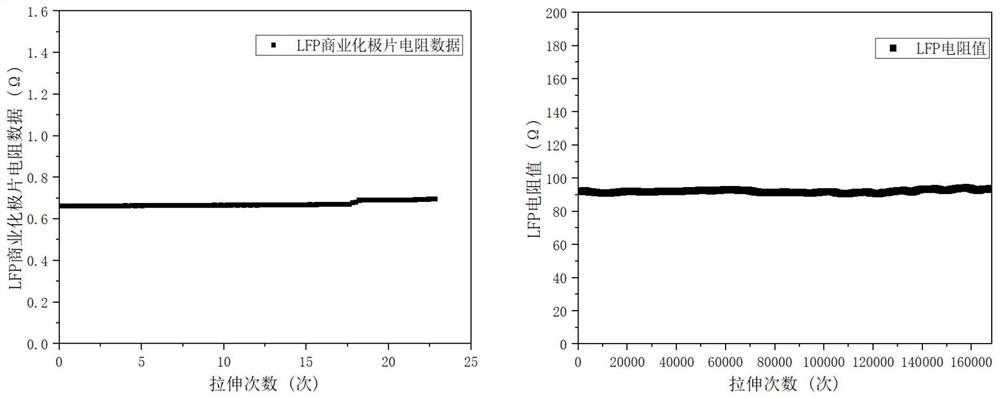

[0092] A kind of lithium iron phosphate (LFP) is active material and prepares multilayer LFP pole piece, and preparation method is as follows:

[0093] 1. Mix PVDF and NMP solution with a purity of 99.9% in a mass ratio of 8:92, and use magnetic stirring for 12 hours to fully stir to prepare an 8% PVDF solution;

[0094] 2. Weigh 1.54g of LFP powder and 0.14g of Super P respectively, grind them with a mortar for 0.5h after mixing, and then place them in a blast oven for 30min;

[0095] 3. Add the raw materials obtained in step (2), 0.5g LB117-NMP carbon nanotubes (solid content is 4%), 0.85g NMP solution with a purity of 99.9%, and 3.75g PVDF obtained in step (1) in the bottle at one time Solution, placed on a magnetic stirrer, the speed is 150r min -1 , the mixing time is 12h;

[0096] 4. Coat the slurry obtained in step (3) with a thickness of 400 μm on the front side of the aluminum foil, and then place it in a vacuum oven at 80° C. for 8 hours;

[0097] 5. Remove the po...

Embodiment 2

[0099] A kind of lithium cobaltate (LCO) is active material and prepares multi-layer LCO pole piece, and preparation method is as follows:

[0100] 1. Mix PVDF and NMP solution with a purity of 99.9% in a mass ratio of 8:92, and use magnetic stirring for 12 hours to fully stir to prepare an 8% PVDF solution;

[0101] 2. Weigh 1.66g of LCO powder and 0.14g of Super P respectively, grind them with a mortar for 0.5h after mixing, and then place them in a blast oven for 30min;

[0102] 3. Add the raw materials obtained in step (2), 0.5g of LB117-NMP carbon nanotubes, 0.5g of NMP solution with a purity of 99.9%, and 2.5g of the PVDF solution obtained in step (1) into the bottle, and place them on a magnetic stirrer , the speed is 120r min -1 , the mixing time is 12h;

[0103] 4. Coat the slurry obtained in step (3) with a thickness of 400 μm on the front side of the aluminum foil, and then place it in a vacuum oven at 80° C. for 8 hours;

[0104] 5. Remove the pole piece obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap