Sterilization line cleaning method and sterilization line

A technology for processing lines and cleaning liquids, applied in chemical instruments and methods, liquid processing, cleaning methods and utensils, etc., can solve the problems of expensive equipment investment, increased number of valves, complex valve structure, etc. The valve structure is simplified, the effect of lightening the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

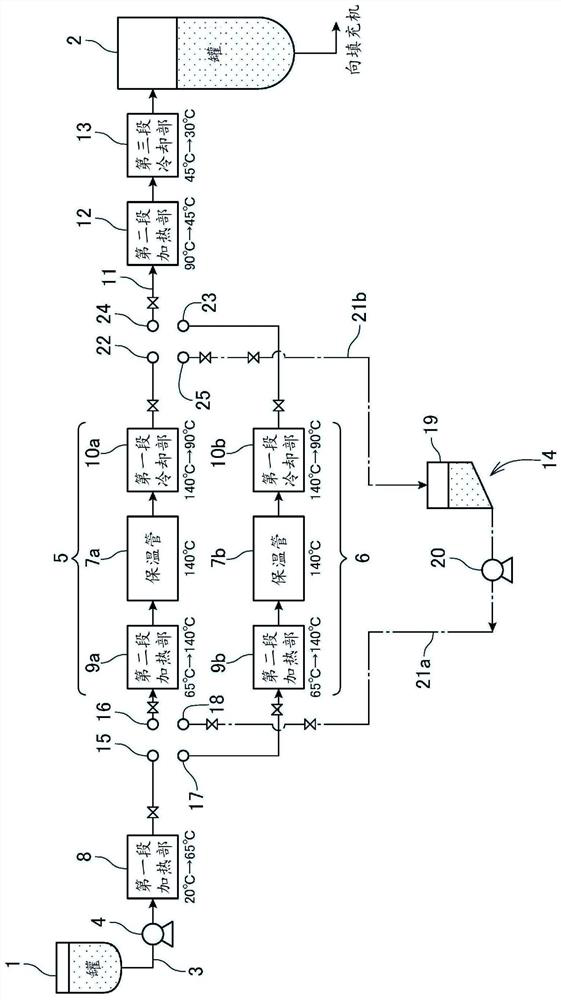

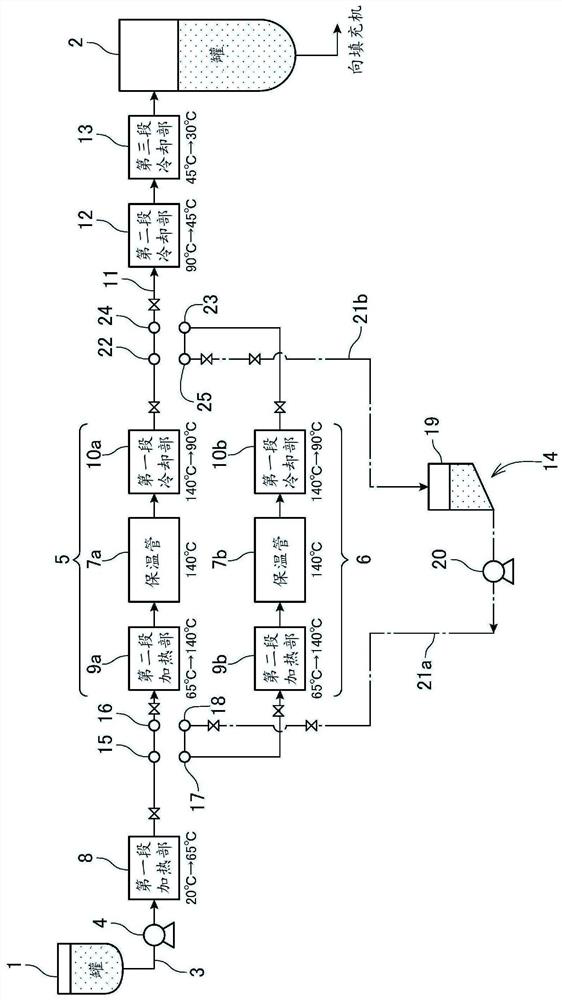

[0042] Installed in the piping system of the aseptic filling machine that handles large-capacity beverages and other product liquids figure 1 Sterilization treatment line as shown.

[0043] exist figure 1 In the figure, reference numeral 1 indicates an upstream side tank for storing a product liquid such as a prepared unsterilized beverage, and reference number 2 indicates a downstream side tank for temporarily storing the sterilized product liquid before supplying it to a filling machine not shown in the figure. .

[0044] The upstream side tank 1 and the downstream side tank 2 can each store a large-capacity product liquid, for example, each has a volume capable of storing several tons to a dozen tons of the product liquid. In addition, the upstream tank 1 keeps the product liquid before sterilization at normal temperature, for example, about 20°C, and the downstream tank 2 keeps the product liquid after sterilization at normal temperature, for example, about 30°C.

[004...

Embodiment approach 2

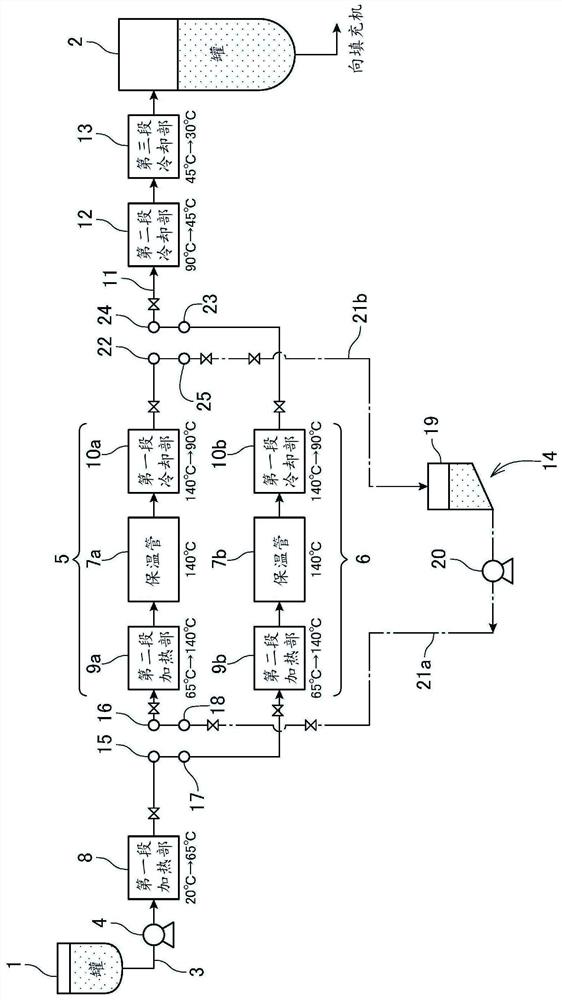

[0070] In Embodiment 2, instead of performing only CIP in the intermediate piping system as in Embodiment 1 for the intermediate piping system on standby, SIP is performed after CIP, and positive pressure processing is further performed. By performing SIP in the intermediate piping system, positive pressure processing is performed and the standby is performed. Therefore, after the flow path is switched, SIP is not performed on the intermediate piping system, the downstream side pipe 11, and the downstream side tank 2, and the previous product liquid After removal, a new product liquid can be supplied immediately, and compared with the case of Embodiment 1, switching time can be shortened significantly, and productivity can be improved.

[0071] Such as Figure 5 As shown, in addition to the sterilization treatment line of Embodiment 1, the sterilization treatment line of Embodiment 2 is provided with a SIP device 27 that performs SIP to sterilize the interior of the intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com