Integrated auxiliary machine SCR reactor platform

An SCR reactor, an integrated technology, applied in chemical instruments and methods, ships, dispersed particle separation, etc., can solve problems such as affecting the efficiency of ship loading, and achieve the effect of reducing resonance, ensuring the strength of the base, and reducing the adjustment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

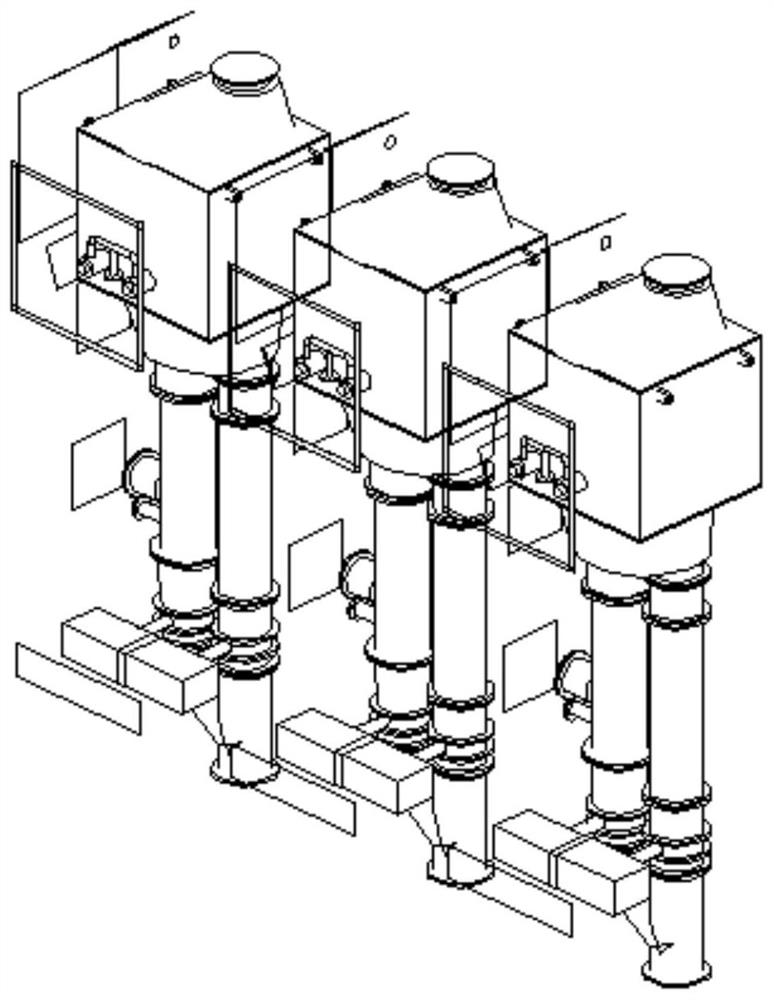

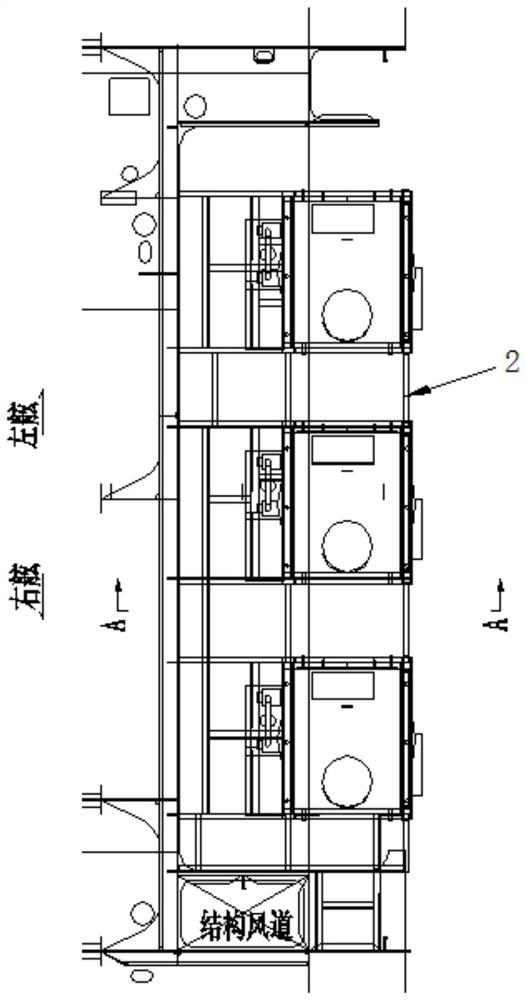

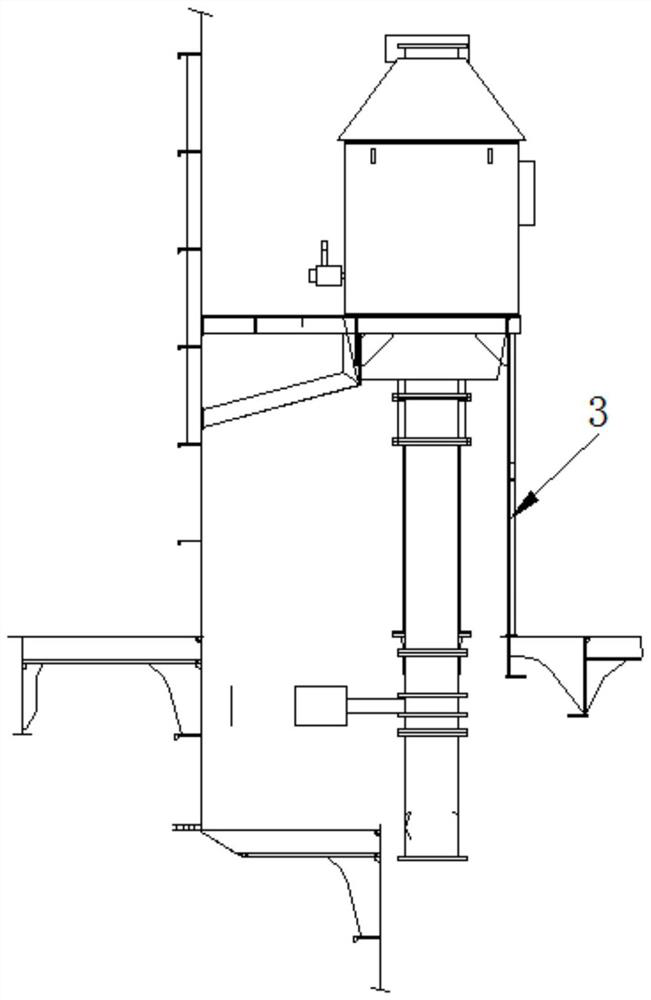

[0032] Such as Figure 1 to Figure 13 shown (for ease of illustration, Figure 1 to Figure 10 The safety rope storage box, the prompt identification layer, the button hole and the digital identification layer are not shown), the present invention is an integrated auxiliary machine SCR reactor platform, including an integrated platform in a frame structure, on which there are at least three An opening 1 for placing the SCR reactor of the auxiliary machine. The platform is fixed by several angle steels or flat steels or channel steels. The opening 1 is set on the top of the platform, and the side of the platform is provided with a common base inspection platform with a frame structure. The public base maintenance platform is welded by angle steel, flat steel or channel steel, each public base maintenance platform includes a top beam 2 as the top side of the platform, and each public base maintenance platform also includes two welded top beams 2 The handrails 3 are vertically ar...

Embodiment 2

[0034] Such as Figure 14 As shown, including the reactor body, three SCR reactors are placed side by side in the reactor body 9, an air inlet 10 and an air outlet 11 are arranged on the reactor body, and several SCR reactors are arranged between the reactor body and the exhaust gas discharge port 12. A general pipeline composed of several modules 13, the modules are provided with a plurality of tunnels 14, which are respectively horizontal holes, longitudinal holes and oblique holes, and the tunnels between adjacent modules are connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com