Coal gangue imitation stone and preparation method thereof

A technology of coal gangue and stone imitation, which is applied in the field of coal gangue imitation stone and its preparation, can solve the problem that the compressive strength and flexural strength of coal gangue imitation stone are low, the visual effect of coal gangue imitation stone is not good, and the product does not meet the national standard. Standards and other issues to achieve the effect of improving compressive strength and flexural strength, compressive strength and flexural strength, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

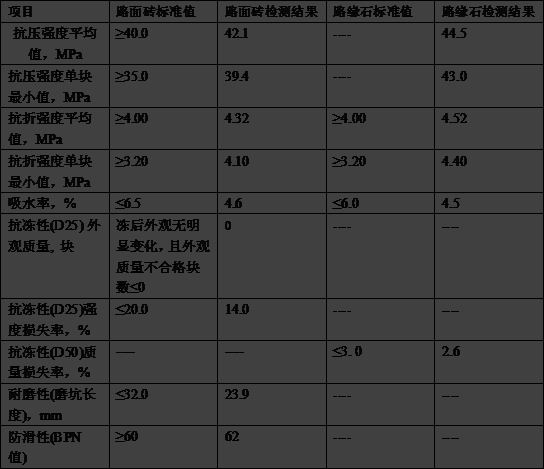

Examples

Embodiment 1

[0026] A coal gangue imitation stone, the coal gangue imitation stone is composed of the following components by weight: 13 parts of first coal gangue, 18 parts of second coal gangue, 23 parts of third coal gangue, 18 parts of cement, and 4 parts of bentonite , 1.5 parts of silicon powder, 0.15 parts of carbon fiber, 0.05 parts of rubber powder, 0.4 parts of reinforcing agent, 0.15 parts of anti-corrosion agent, 11 parts of water; the first coal gangue is coal gangue with a particle size of 4mm, the second coal gangue is The gangue is coal gangue with a particle size of 2.5mm, and the third coal gangue is a coal gangue with a particle size of 1.5mm; the reinforcing agent is used to enhance the compressive strength and flexural strength of the coal gangue imitation stone, so that the The compressive strength and flexural strength of the output coal gangue imitation stone conform to the national standard; the cement is Portland cement with a strength grade of 52.5, the reinforcin...

Embodiment 2

[0037] A coal gangue imitation stone, the coal gangue imitation stone is composed of the following components in parts by weight: 17 parts of the first coal gangue, 22 parts of the second coal gangue, 27 parts of the third coal gangue, 22 parts of cement, and 6 parts of bentonite , 2.5 parts of silicon powder, 0.25 parts of carbon fiber, 0.15 parts of rubber powder, 0.6 parts of reinforcing agent, 0.25 parts of anti-corrosion agent, and 13 parts of water; the first coal gangue is coal gangue with a particle size of 6mm, and the second coal gangue The gangue is coal gangue with a particle size of 3.5mm, and the third coal gangue is a coal gangue with a particle size of 2.2mm; the reinforcing agent is used to enhance the compressive strength and flexural strength of the coal gangue imitating stone, so that the The compressive strength and flexural strength of the output coal gangue imitation stone conform to the national standard; the cement is Portland cement with a strength gra...

Embodiment 3

[0048] A coal gangue imitation stone material, the coal gangue imitation stone material is composed of the following components by weight: 15 parts of the first coal gangue, 20 parts of the second coal gangue, 25 parts of the third coal gangue, 20 parts of cement, and 5 parts of bentonite , 2 parts of silicon powder, 0.2 part of carbon fiber, 0.1 part of rubber powder, 0.5 part of reinforcing agent, 0.2 part of anti-corrosion agent, 12 parts of water; the first coal gangue is a coal gangue whose particle size is 5mm, and the second coal gangue Gangue is coal gangue with a particle size of 3 mm, and the third gangue is coal gangue with a particle size of 2 mm; the reinforcing agent is used to enhance the compressive strength and flexural strength of the gangue imitation stone, so that the output The compressive strength and flexural strength of the coal gangue imitation stone meet the national standard; the cement is Portland cement with a strength grade of 52.5, the reinforcing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com