Preparation method of m-phenoxy benzaldehyde

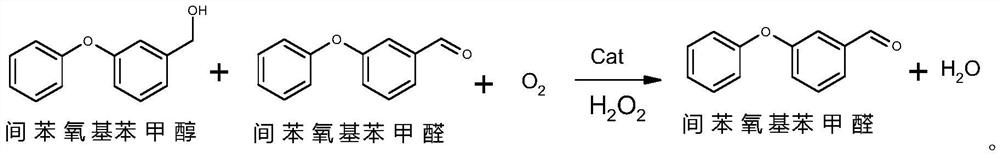

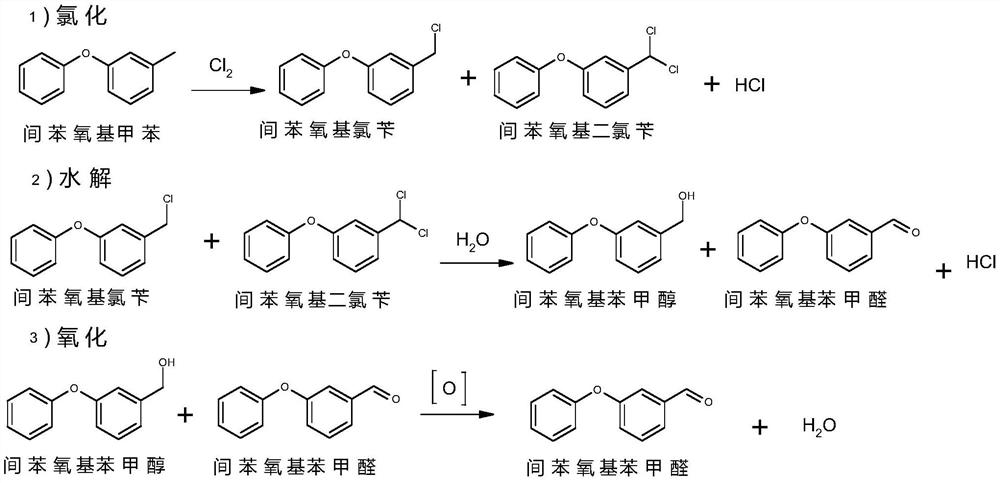

A technology of m-phenoxybenzaldehyde and m-phenoxybenzyl alcohol, applied in the field of preparation of m-phenoxybenzaldehyde, can solve the problems of inapplicability to industrial production, high production cost, difficult treatment of waste water and waste residue, etc., and achieve reaction The effect of short cycle, high yield and stable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

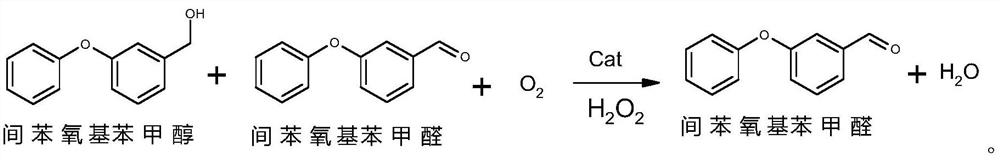

Method used

Image

Examples

Embodiment 1

[0033] In the 1500L reactor, drop into 1000Kg of the mixture of ether aldehyde and ether alcohol (containing ether alcohol 35%), add 20Kg water, 5kg hydrogen peroxide, 0.5Kg ferrous sulfate, 0.4Kg gac (specific surface area is 800m 2 / g), stir and heat up to 45-55 degrees, feed oxygen (content 99%) for 2hr, the content of ether alcohol in the central control reactant is 0.11%, stop oxygen feeding, filter the reaction solution through a pressure filter tank, and let the filtrate stand Add 0.1Kg hydrochloric acid (mass fraction 30%) to adjust pH=6, let stand for 1hr to separate layers, the oil layer is 999.5Kg of crude ether aldehyde, the content is 98.32% (containing ether alcohol 0.08%, containing m-phenoxybenzoic acid 0.09%) , the oxidation yield was 98.6%. The oil layer is simply evaporated to obtain refined ether aldehyde with a content of 99.2%.

Embodiment 2

[0035] In the 1500L reactor, drop into 1000Kg of the mixture of ether aldehyde and ether alcohol (containing ether alcohol 65%), add 20Kg water, 5kg hydrogen peroxide, 0.5Kg ferrous sulfate, 0.4Kg gac (specific surface area is 800m 2 / g), stir and heat up to 45-55 degrees, feed oxygen (content 99%) for 2.5hr, the content of ether alcohol in the central control reactant is 0.20%, stop oxygen feeding, the reaction solution is filtered through the pressure filter tank, and the filtrate is static Add 0.12Kg hydrochloric acid (mass fraction 30%) to adjust pH=6, let stand for 1hr to separate layers, and the oil layer is 996Kg of crude ether aldehyde, with a content of 98.9% (containing 0.05% ether alcohol and 0.05% m-phenoxybenzoic acid) , the oxidation yield was 99.15%. The oil layer is simply evaporated to obtain refined ether aldehyde with a content of 99.35%.

Embodiment 3

[0037] Put 1000Kg of the mixture of ether aldehyde and ether alcohol into the 1500L reactor (containing ether alcohol 65%), add 10Kg water, 2kg hydrogen peroxide, 0.35Kg ferrous sulfate, 0.2Kg activated carbon (the specific surface area is 800m 2 / g), stir and heat up to 45~50 degrees, pass into oxygen (content 99%) 3.0hr, the ether alcohol content in the control reactant is 0.15%, stop the oxygen flow, the reaction solution is filtered through the pressure filter cylinder, the filtrate is static Add 0.12Kg hydrochloric acid (mass fraction 30%) to adjust pH=6, let stand for 1hr to separate layers, the oil layer is 994Kg of crude ether aldehyde, the content is 98.5% (containing ether alcohol 0.07%, containing m-phenoxybenzoic acid 0.08%) , the oxidation yield was 98.55%. The oil layer is simply evaporated to obtain refined ether aldehyde with a content of 99.22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com