Selective hydrogenation method of conjugated diene latex

A conjugated diene and selective technology, which is applied in the field of selective hydrogenation of conjugated diene latex to achieve the effects of low usage, rapid industrialization, and less severe hydrogenation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

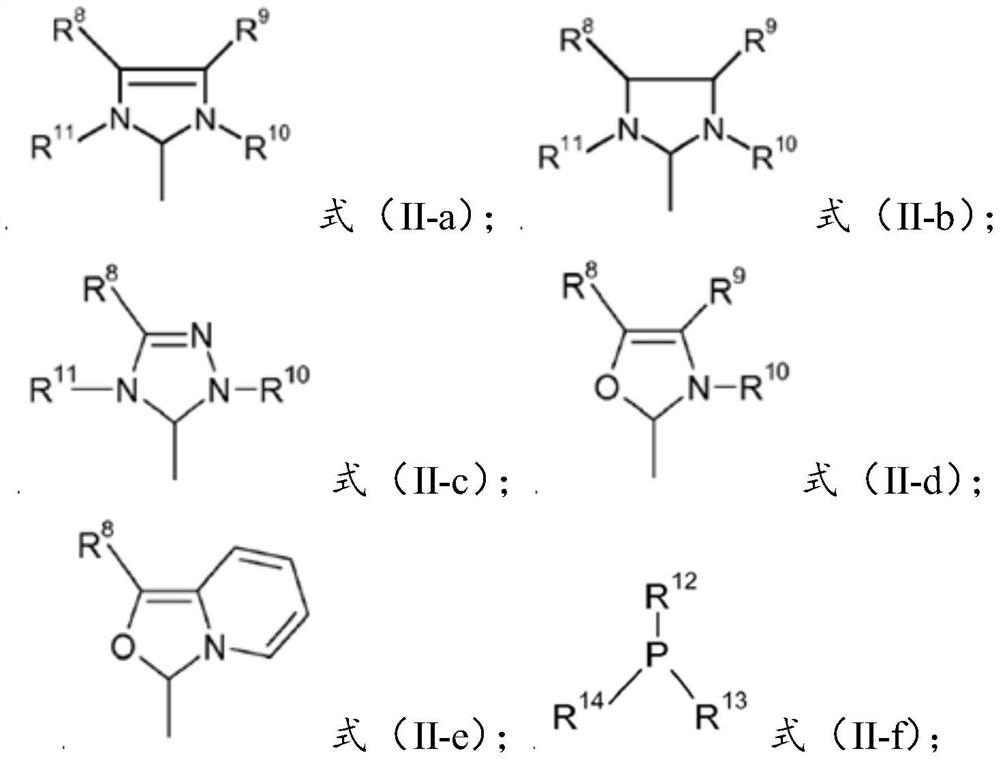

Method used

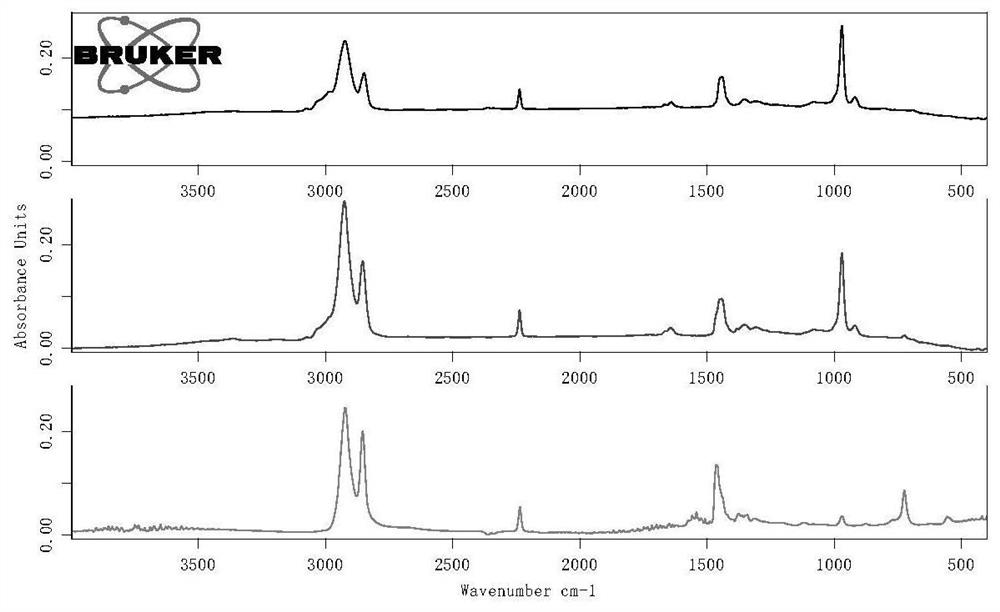

Image

Examples

Embodiment 1

[0150] Catalyst using hydrogen degassing process

[0151] A 300 mL stainless steel high pressure reactor (Parr Instruments) with temperature control, stirrer and hydrogen addition point was used. A smooth butadiene-acrylonitrile polymer latex with a limited acrylonitrile content of about 33% by weight and a Mooney viscosity (ML1+4 @ 100°C) of about 55 was used. The solids content of the latex was 23.6% by weight. The average diameter of the polymer particles in the latex is about 88 nm. 100 ml of this latex, 0.000236 g of Hevida-Grubbs II catalyst were charged to the reactor. Then feed hydrogen to keep the system pressure at 2 MPa, and bubble at room temperature for 60 minutes to degas the latex. The temperature was raised to 110°C and the hydrogen pressure was increased to 1100 psi (7.58 MPa). After reacting for 8 hours, after the reaction, the hydrogenated NBR latex was coagulated with ethanol to obtain a HNBR copolymer. The condensate was then dissolved in MEK to analy...

Embodiment 2

[0154] Catalyst using hydrogen degassing process 2

[0155] A 300 mL stainless steel high pressure reactor (Parr Instruments) with temperature control, stirrer and hydrogen addition point was used. A smooth butadiene-acrylonitrile polymer latex with a limited acrylonitrile content of about 33% by weight and a Mooney viscosity (ML1+4 @ 100°C) of about 55 was used. The solids content of the latex was 23.6% by weight. The average diameter of the polymer particles in the latex is about 88 nm. 100 ml of this latex, 0.000236 g of Hevida-Grubbs II catalyst were charged to the reactor. Then, hydrogen was introduced to keep the system pressure at 2MPa, and the latex was degassed by bubbling at room temperature for 30 minutes. The temperature was raised to 110°C and the hydrogen pressure was increased to 1100 psi (7.58 MPa). After reacting for 8 hours, after the reaction, the hydrogenated NBR latex was coagulated with ethanol to obtain a HNBR copolymer. The condensate was then diss...

Embodiment 3

[0158] Catalyst using hydrogen degassing process3

[0159] A 300 mL stainless steel high pressure reactor (Parr Instruments) with temperature control, stirrer and hydrogen addition point was used. A smooth butadiene-acrylonitrile polymer latex with a limited acrylonitrile content of about 33% by weight and a Mooney viscosity (ML1+4 @ 100°C) of about 55 was used. The solids content of the latex was 23.6% by weight. The average diameter of the polymer particles in the latex is about 88 nm. 100 ml of this latex, 0.000236 g of Hevida-Grubbs II catalyst were charged to the reactor. Then, hydrogen was introduced to keep the system pressure at 1MPa, and the latex was degassed by bubbling at room temperature for 60 minutes. The temperature was raised to 110°C and the hydrogen pressure was increased to 1100 psi (7.58 MPa). After reacting for 8 hours, after the reaction, the hydrogenated NBR latex was coagulated with ethanol to obtain a HNBR copolymer. The condensate was then disso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com