Thiopolyphosphate as well as preparation method and application thereof

A technology of thiopolyphosphate and polyphosphate, applied in the field of polymer materials, can solve the problems of affecting the degradation process and speeding up the degradation of polyphosphates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] The present invention also provides a preparation method of polythiophosphate, comprising: mixing and reacting the phosphorothioate monomer shown in formula (III), initiator and catalyst under anhydrous conditions to obtain ) structure of thiopolyphosphate; wherein, the initiator is a polymer compound initiator with a hydroxyl group at the end, a polylactone compound with a hydroxyl group at the end, a small molecular compound initiator containing a hydroxyl group or a small molecule compound containing a hydroxyl salt Molecular compound initiator;

[0076] Or polymerize the monomer represented by formula (II) to obtain polythiophosphate;

[0077]

[0078] Among them, R 1 It is the residue after one hydroxyl group is removed from a polymer compound with a hydroxyl group at the end, the residue after one hydroxyl group is removed from a hydroxyl-containing small molecule compound, or the residue after one hydroxyl group is removed from a polylactone compound; R 2 is...

Embodiment 1

[0104] Embodiment 1: Oxyphosphoryl chloride CTP is the synthesis of the compound shown in formula (V)

[0105]

[0106] All reactants were purified by vacuum distillation before the reaction started. The reaction needs to be carried out under anhydrous conditions, and phosphorus trichloride is dissolved in anhydrous dichloromethane to keep the reactant concentration at 1.0mol / L, constantly stir at room temperature, then slowly add dropwise the dichloromethane solution of ethylene glycol ( 1.0mol / L), wherein the molar ratio of phosphorus oxychloride to ethylene glycol is 1:1, and the HCI generated by the reaction is absorbed in time with solid sodium hydroxide. After 6 hours, the reaction was completed, and the solvent was removed by a rotary vane vacuum pump, and purified by distillation under reduced pressure to obtain cyclic trivalent phosphorus oxychloride as a colorless clear liquid with a pungent smell. Dissolve cyclic trivalent phosphorus oxychloride in anhydrous ben...

Embodiment 2

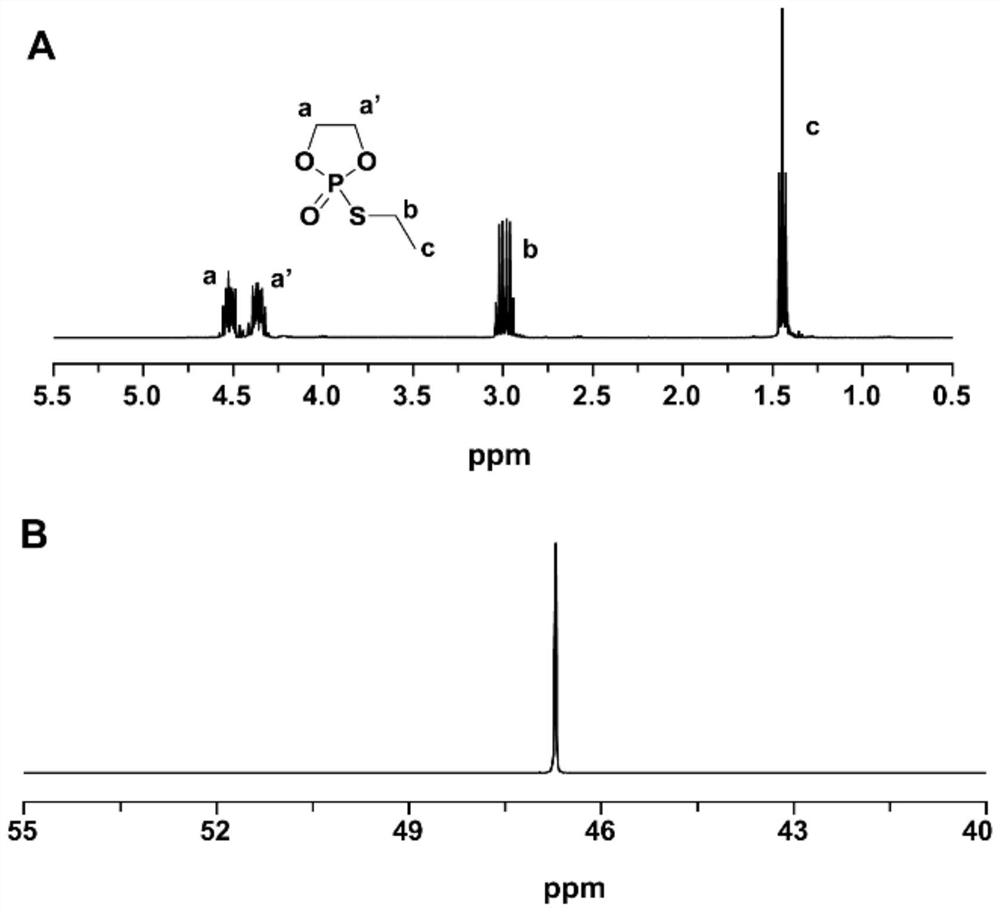

[0108] Embodiment 2: the synthesis of phosphorothioate monomer

[0109]

[0110] R:-CH 3 -CH 2 CH 3 -CH 2 CH 2 CH 3 -CH 2 CH 2 CH 2 CH 3 -CH 2 CH 2 CH 2 CH 2 CH 3 -CH 2 CH 2 CH 2 CH 2 CH 2 CH 3

[0111] Before the reaction starts, the reactants and the solvent are all dried. The reaction must be carried out under anhydrous conditions, and the device is a three-necked flask containing a constant pressure dropping funnel, and the molar ratio is acid chloride:alcohol:triethylamine=1:1:1. Utilize heating and vacuum condition to remove a small amount of water contained in the reaction device, the concrete reaction is as follows:

[0112] First add anhydrous tetrahydrofuran to the three-necked flask, and then add methyl mercaptan to keep its concentration at 1.0 mol / L. Add triethylamine therein again, drop the compound shown in formula (V) to reaction device through dropping funnel. The reaction was carried out at 0°C for 10 h, and a white precipitate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com