Digital banner fabric preparation process with high coloring rate and low water leakiness

A technology of preparation process and coloring rate, which is applied in the cutting of textile materials, fabrics, textiles, etc., can solve the problems of poor waterproof effect, shortened display life, and low coloring rate of digital banner cloth, so as to improve adhesion and coloring Effect of performance and waterproof performance, excellent moisture absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

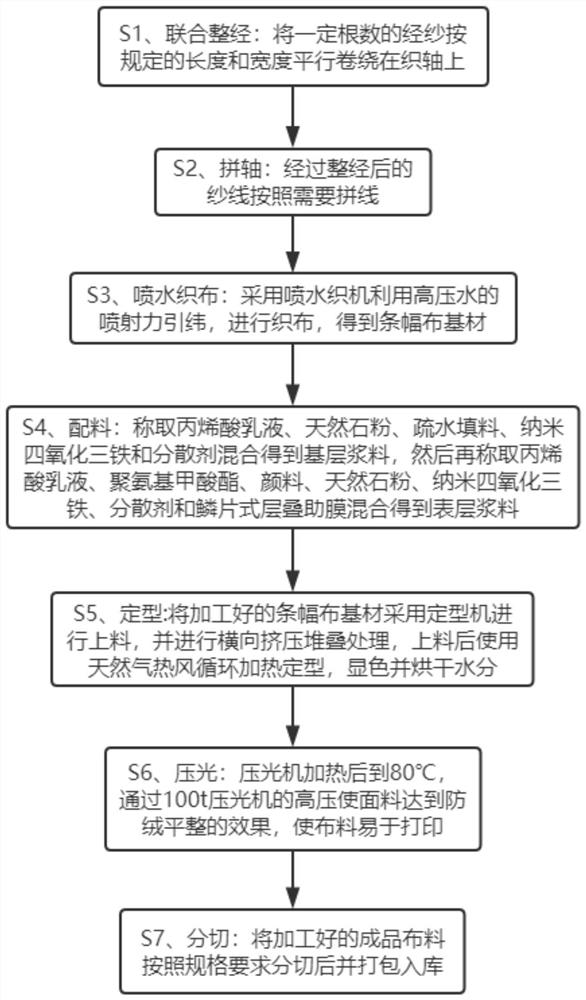

[0048] see Figure 1-2 , a digital banner cloth preparation process with high coloring rate and low water permeability, comprising the following steps:

[0049] S1. Combined warping: winding a certain number of warp yarns in parallel on the weaving beam according to the specified length and width;

[0050] S2. Shaft splicing: the warped yarns are spliced according to the needs;

[0051] S3. Water-jet weaving: Water-jet looms are used to insert wefts by the jet force of high-pressure water to weave fabrics to obtain banner fabric base material 1. Since weft insertion depends on water flow, there is no hard friction during the weaving process of warp and weft filaments, and the quality of the fabric is improved. it is good;

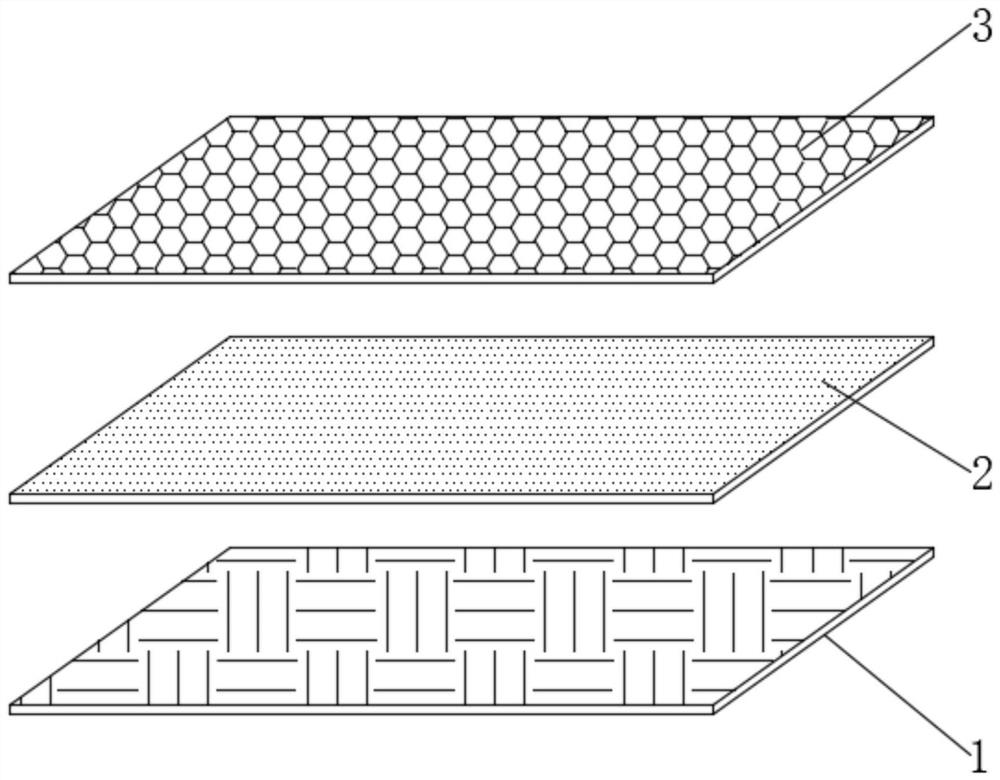

[0052] S4. Ingredients: Weigh acrylic emulsion, natural stone powder, hydrophobic filler 201, nano-ferric oxide and dispersant to mix to obtain base layer slurry, and then weigh acrylic emulsion, polyurethane, pigment, natural stone powder, nano-SiO Fe...

Embodiment 2

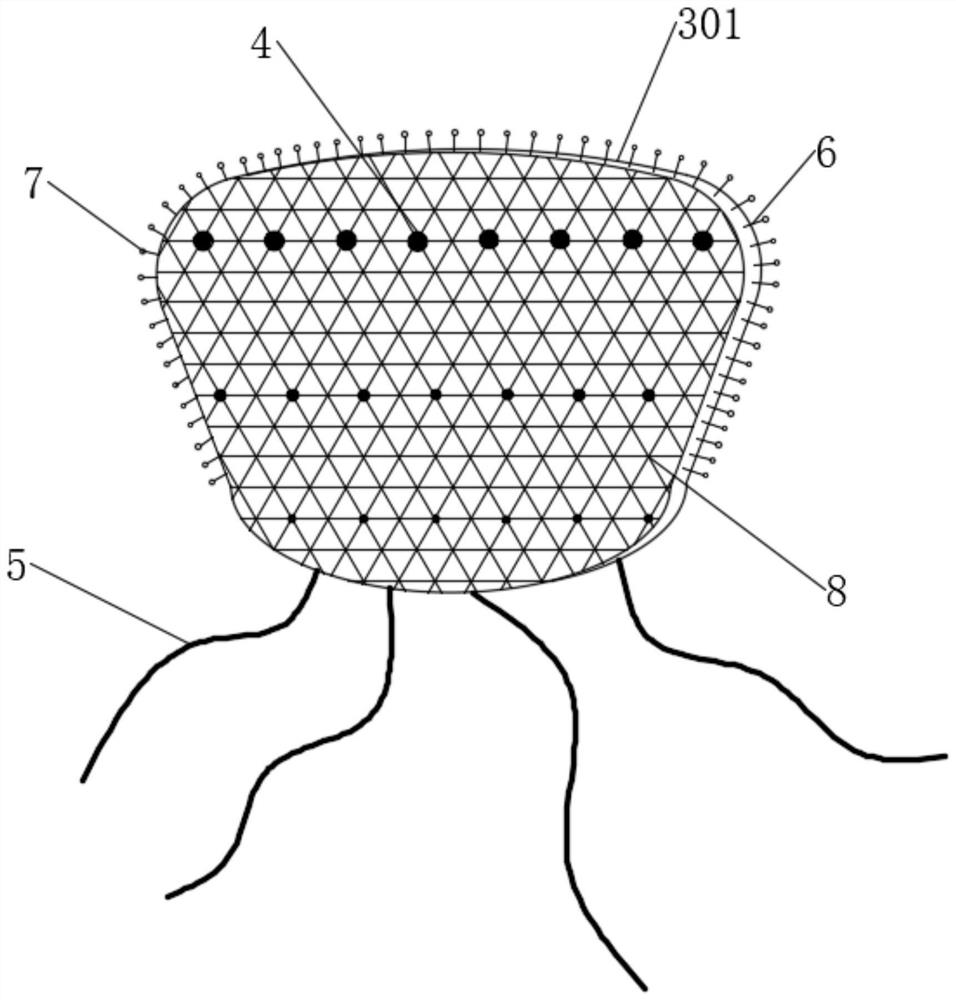

[0065] The base layer slurry includes the following raw materials in parts by weight: 25 parts of acrylic acid emulsion, 18 parts of natural stone powder, 10 parts of nanometer ferric oxide and 1.3 parts of dispersant, and the surface layer slurry includes the following raw materials in parts by weight: 12 parts of acrylic acid emulsion, 10 parts of polyurethane, 12 parts of pigment, 5 parts of natural stone powder, 4 parts of hydrophobic filler 201, 8 parts of nano-ferric oxide, 1.8 parts of dispersant and 15 parts of scale-type lamination auxiliary film 301.

[0066] In step S5, the base layer slurry is first applied, dried at 90°C for 8 minutes until it is not fully cured, and then the surface layer slurry is applied at a temperature of 110°C for 20 minutes until it is completely cured to obtain a well-bonded dense base layer 2 and scale surface layer 3, improving the density of the base layer 2 and the bonding force of the scale surface 3 prevents the phenomenon of peeling ...

Embodiment 3

[0069] The base layer slurry includes the following raw materials in parts by weight: 30 parts of acrylic acid emulsion, 20 parts of natural stone powder, 12 parts of nano-ferric oxide and 1.6 parts of dispersant, and the surface layer slurry includes the following raw materials in parts by weight: 15 parts of acrylic acid emulsion, 12 parts of polyurethane, 15 parts of pigment, 6 parts of natural stone powder, 5 parts of hydrophobic filler 201, 10 parts of nano ferric oxide, 2 parts of dispersant and 20 parts of scale-type lamination aid film 301.

[0070] In step S5, the base layer slurry is first applied, dried at 00°C for 10 minutes until it is not completely cured, and then the surface layer slurry is applied at a temperature of 120°C for 25 minutes until it is completely cured to obtain a well-bonded dense base layer 2 and scale surface layer 3, improving the density of the base layer. 2 and the bonding force of the scale surface 3 prevents the phenomenon of peeling off f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com