LNG regasification experiment system and experiment method

An experimental system and vaporizer technology, applied in the container filling method, container discharge method, non-pressure container and other directions, can solve the problems of difficult to clean scale, work troubles, affect heat exchange efficiency, etc., to reduce the formation of scale, reduce The effect of icing phenomenon and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

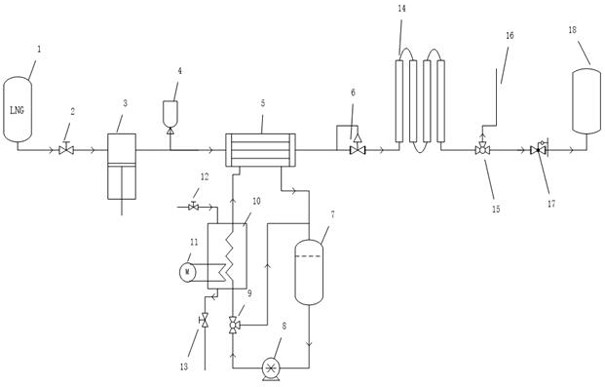

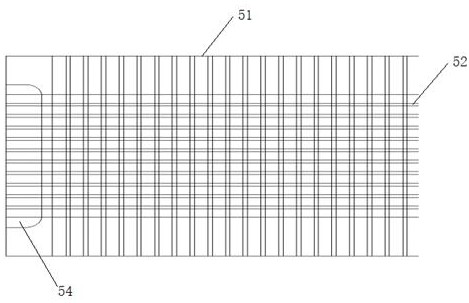

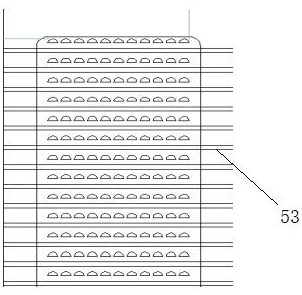

[0036] like Figure 1-Figure 3 A kind of LNG regasification experimental system shown, including

[0037] One LNG circulation unit, the LNG circulation unit includes LNG liquid tank 1, liquid outlet valve 2, plunger type booster pump 3, surge tank 4, microchannel vaporizer 5, back pressure valve 6, air temperature reheater 14, Empty pipe 16, three-way valve I 15, pressure reducing valve 17, liquid storage tank 18, among which, LNG liquid tank 1, liquid outlet valve 2, plunger type booster pump 3, surge tank 4, microchannel vaporizer 5, The back pressure valve 6, the air temperature reheater 14, the three-way valve I15, the pressure reducing valve 17, and the liquid storage tank 18 are sequentially connected through pipelines, and the remaining outlet of the three-way valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com