A system and detection method for detecting the height of tunnel secondary lining fabric based on thermal imaging

A technology of thermal imaging and tunneling, which is applied in image enhancement, image analysis, measuring devices, etc., can solve problems such as hidden safety hazards and increase labor workload of workers, and achieve the effects of eliminating hidden safety hazards, reducing labor workload of workers, and facilitating control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

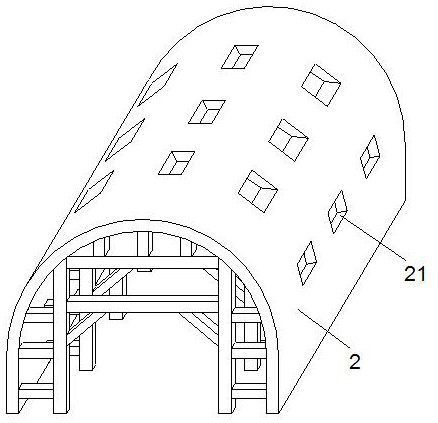

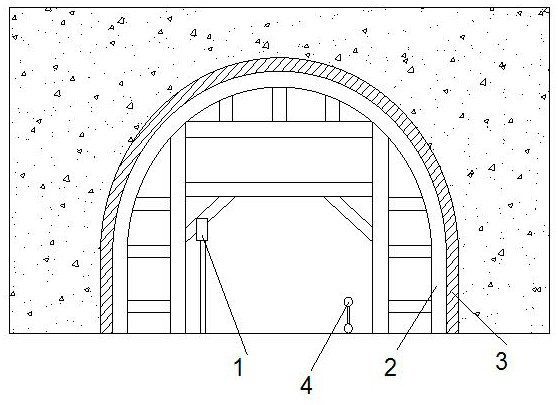

[0015] as attached figure 2 As shown, a system for detecting the height of the second lining of a tunnel based on thermal imaging includes a thermal imaging camera 1, a tunnel trolley 2 and a heat source 4, and the window 21 on the outer surface of the tunnel trolley 2 is closely covered on the inner wall of the tunnel On the surface of the reinforced frame 3, the concrete is continuously conveyed along the pipeline through the concrete delivery pump truck using pressure during pouring, and then the concrete is poured into the reinforced frame 3 between the tunnel trolley 2 and the inner wall of the tunnel through the distributing machine and the chute from the window 21 Carry out the second lining of the tunnel.

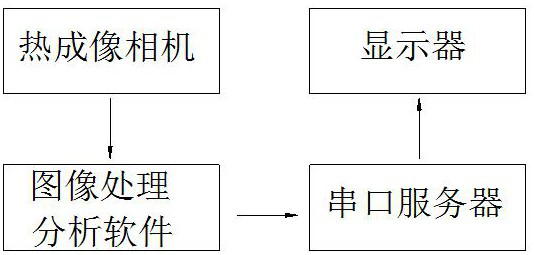

[0016] as attached figure 2 As shown, the thermal imaging camera 1 is movable inside the tunnel trolley 2 , and the thermal imaging camera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com