Thin-film battery discharging device

A thin-film battery and bottom plate technology, which is applied to circuits, electrical components, transportation and packaging, etc., can solve the problems of different sizes of thin-film batteries and affect the processing of thin-film batteries, and achieve the effects of easy adjustment, improved production efficiency, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

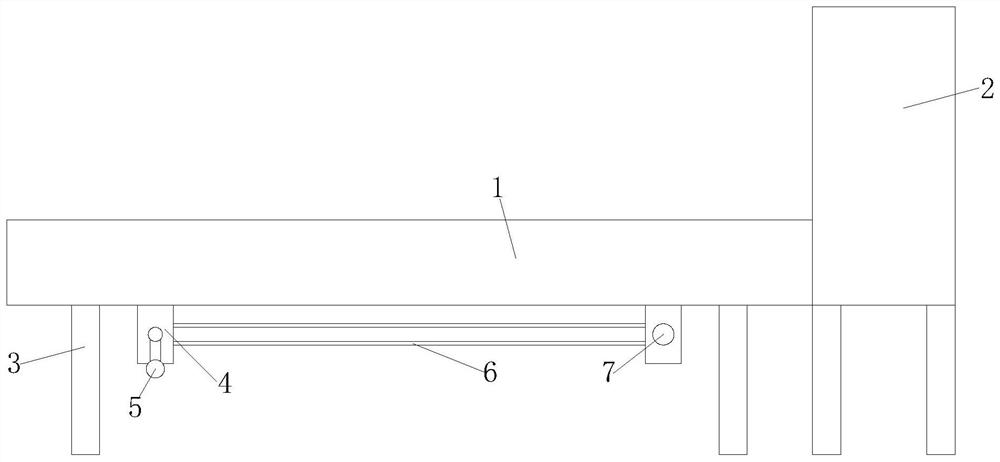

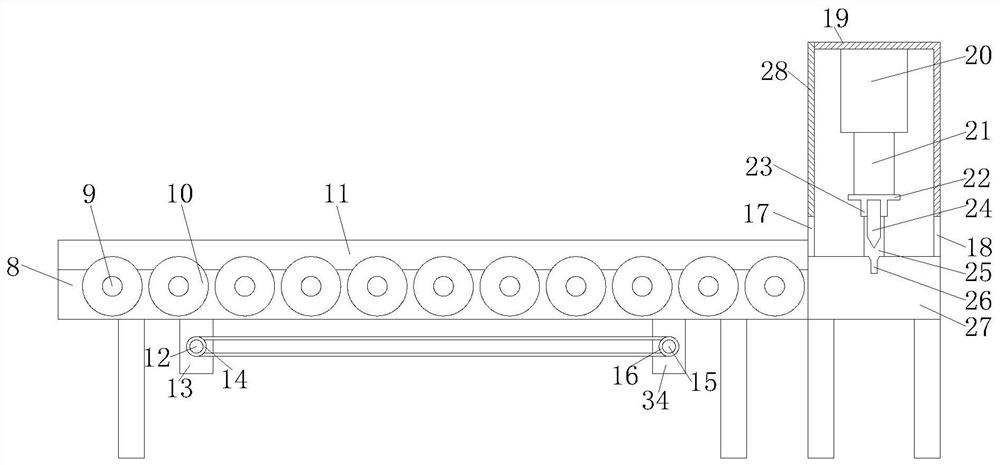

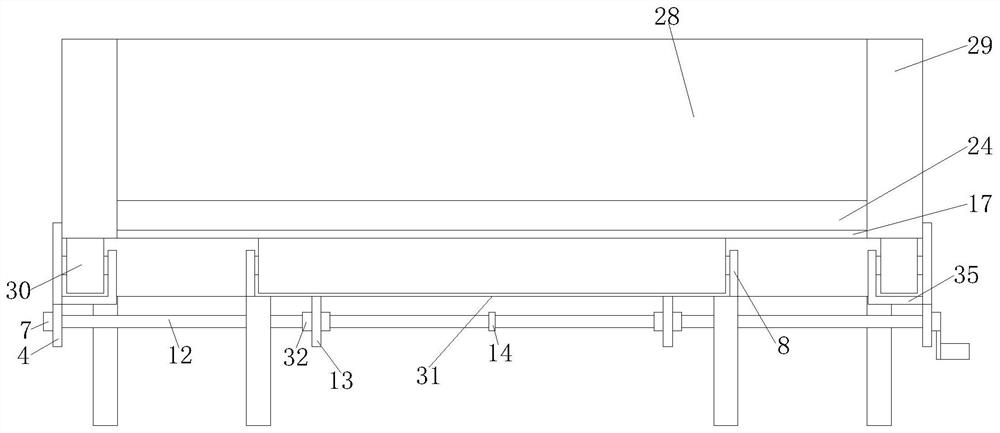

[0026] Such as Figure 1-5 As shown, the present invention provides a kind of technical scheme:

[0027]A thin-film battery unloading device, including a transmission mechanism 1 and a cutting mechanism 2. The thin-film battery is cut by the cutting mechanism 2 and sent to the transmission mechanism 1 for delivery to the next process. The transmission mechanism 1 is provided with a bottom plate 31, which is convenient for installation Fixed ear seat one 13 and fixed ear seat two 34, the front and rear ends of the upper surface of the base plate 31 are fixedly connected with a roller frame 8, and the transmission roller 10 is fixed by the roller frame 8, and a support frame 3 is fixedly installed around the bottom of the base plate 31 to support The frame 3 provides support for the entire transmission mechanism 1, one side of the bottom of the bottom plate 31 is fixedly connected with a fixed ear seat 13, and the other side of the bottom of the bottom plate 31 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com