Integrated desktop neutron generator

A neutron generator, main body technology, applied in the direction of DC voltage accelerator, electrical components, accelerators, etc., can solve the problems of difficulty in implementation, reduced reliability, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

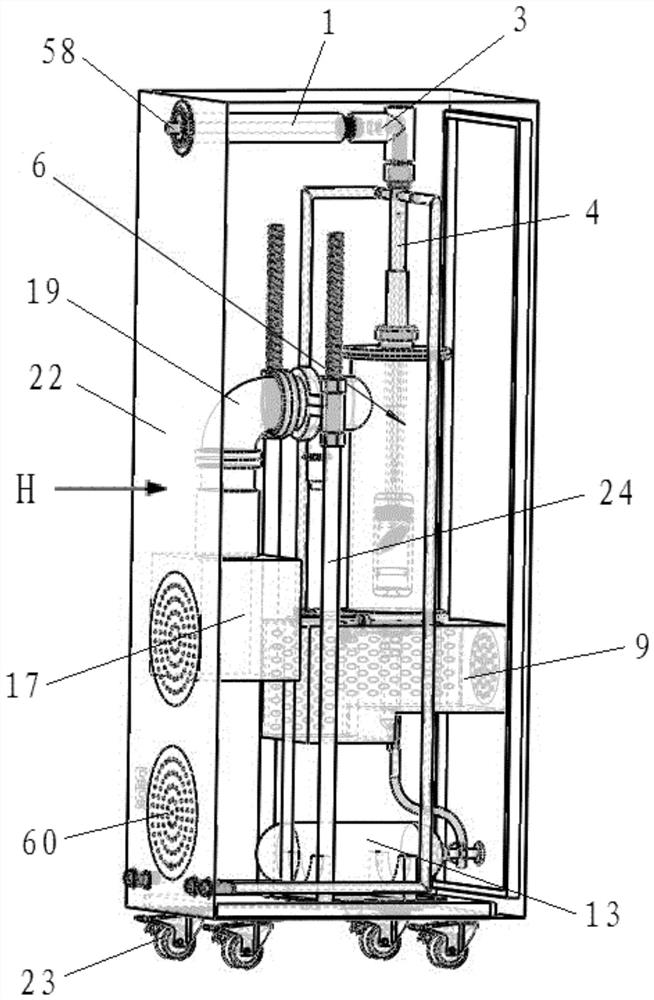

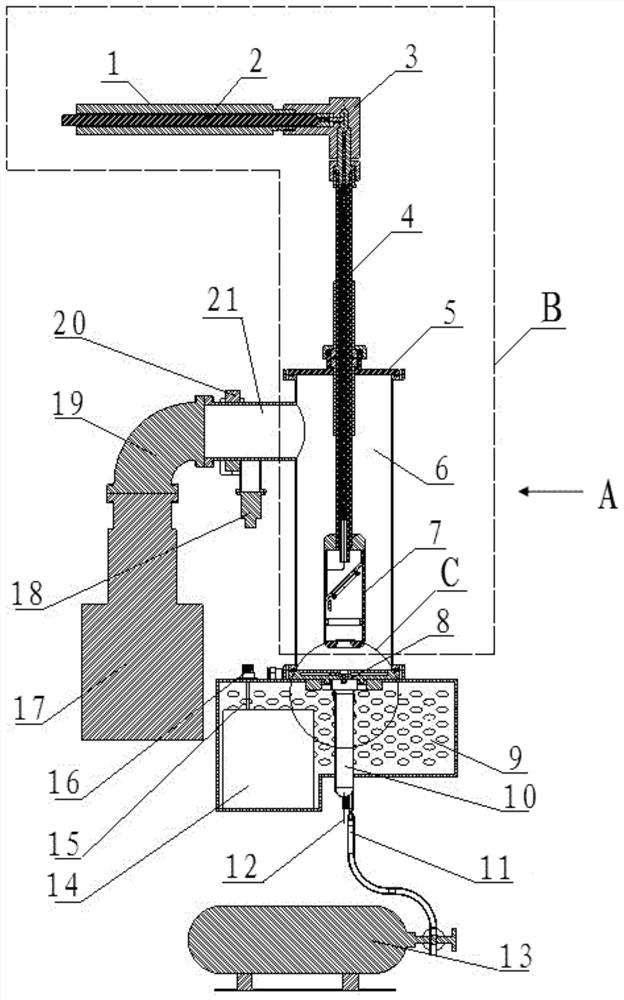

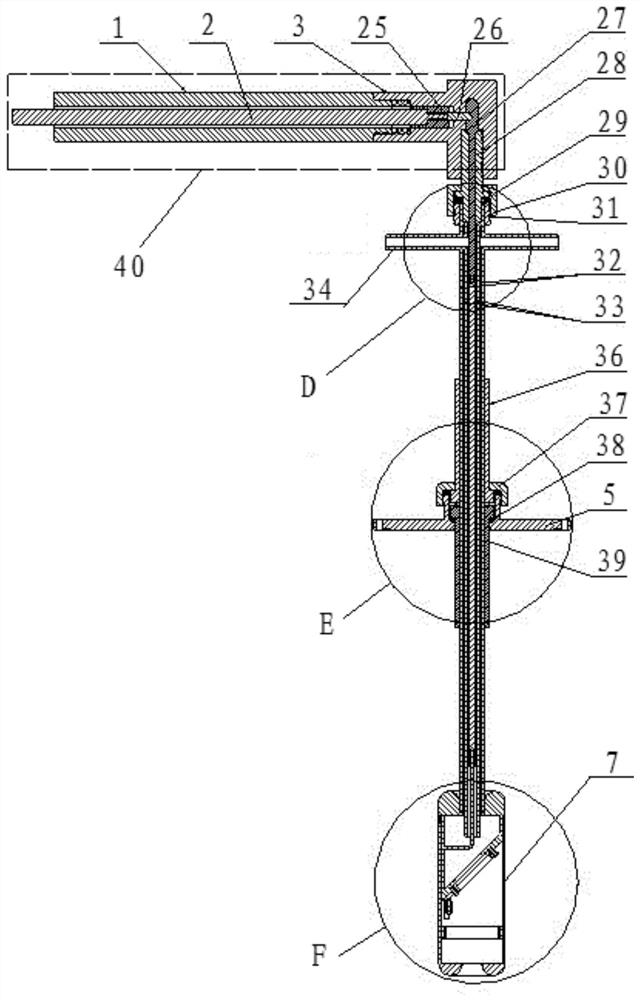

[0092] Such as figure 1 , Figure 8 As shown, a kind of upright neutron generator, comprises the D+ ion source that is arranged in the main body cabinet 22 that can move aluminum material and straight tube type cooling liquid guide pipe 4, and the cooling liquid guide pipe 4 is perpendicular to On the ground, a high-voltage input module 40 is set on the top of the cooling liquid guide pipe 4, and a target electrode 7 is set at the tail end, and the D+ ion source is located below the target electrode 7; a straight vacuum chamber 6 is also included, and one end of the vacuum chamber 6 is connected to the cooling liquid guide tube. The tail end of the flow tube 4 is sealed and connected, and the other end is sealed and connected with the tail end of the D+ ion source. The target electrode 7 is located in the vacuum chamber 6; it also includes a molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com