Oil bath furnace stirring device of integrated workpiece loading cavity

A stirring device and loading chamber technology, which is applied to mixers, furnaces, and furnace types with rotating stirring devices, can solve the problems of sufficient and uniform oil temperature at the bottom of the furnace body, affecting the quality of heat treatment, and uneven heating of workpieces, etc., to avoid Scratch the workpiece, solve the effect of uneven heating and fully uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The solution of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

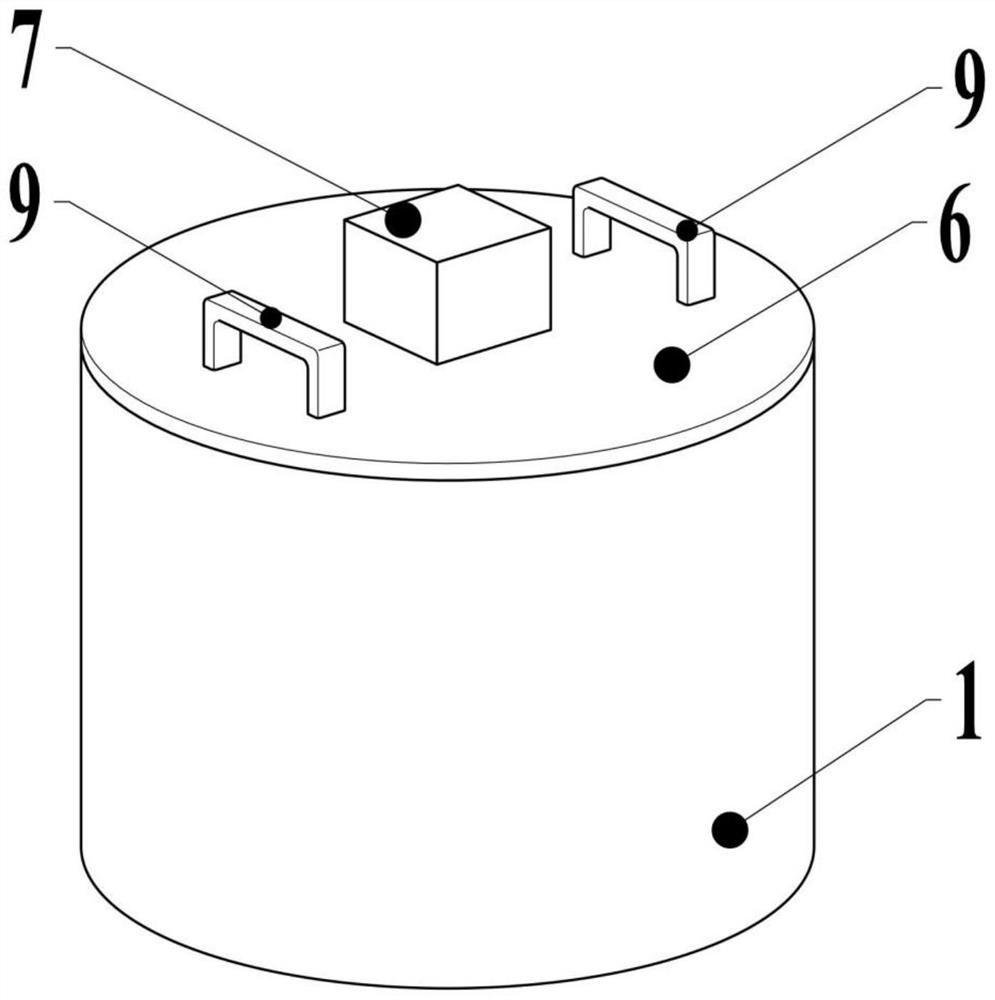

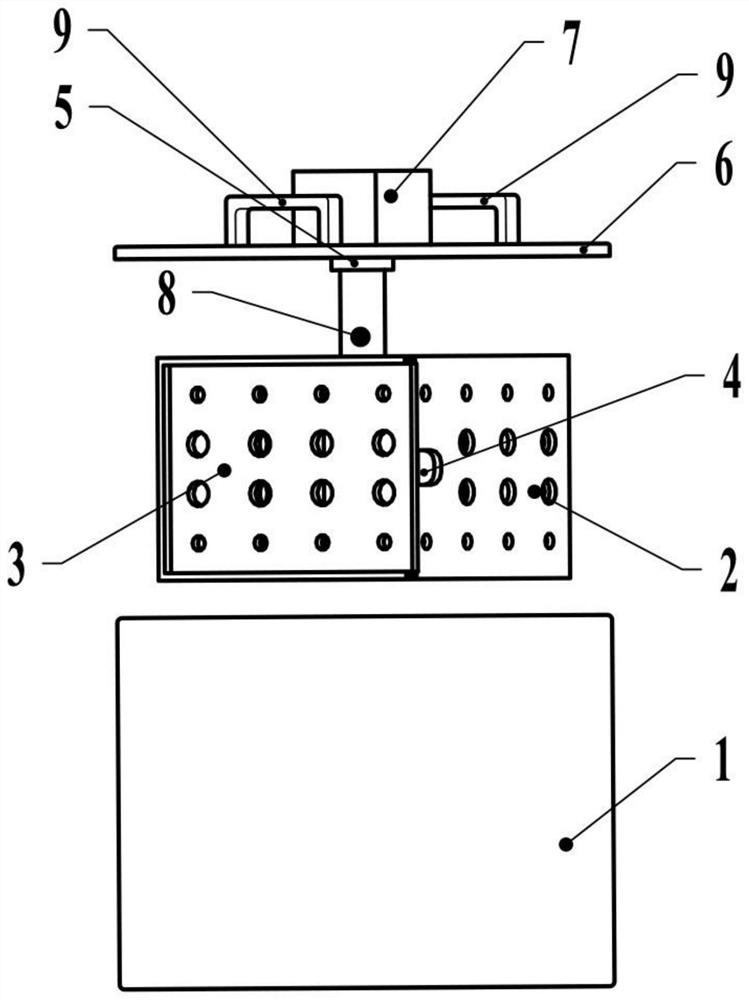

[0014] The present invention proposes a stirring device for an oil bath furnace integrating a workpiece carrier, as attached Figures 1 to 2 As shown, the stirring device is arranged on the furnace body 1, and the stirring device includes a cavity and a driving device; wherein the cavity includes a box body 2, a door panel 3 and a knob 4, and one side of the box body 2 is provided with a door frame with a rectangular guide groove, and the door frame There is a knob 4 on the right end, guide rails are provided on both sides of the door panel 3, and the door panel 3 is installed into the door frame through a rectangular guide groove; each surface of the box body 2 and the door panel 3 are provided with a plurality of holes for oil circulation; the driving device includes a motor 7. Transmission rod 8, bearing 5, furnace cover 6 and handle 9, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com