Hydrogen storage alloy suitable for high-pressure-metal hydride hydrogen storage and preparation method of hydrogen storage alloy

A hydrogen storage alloy and hydride technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of exceeding the optimal use temperature range of IV-type bottles, the proportion of element Cr on the B side is large, and the price of metal Cr is expensive. The effect of improving hydrogen output pressure, fast hydrogen release rate and low alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

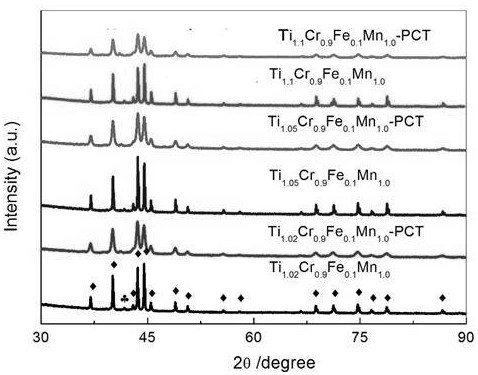

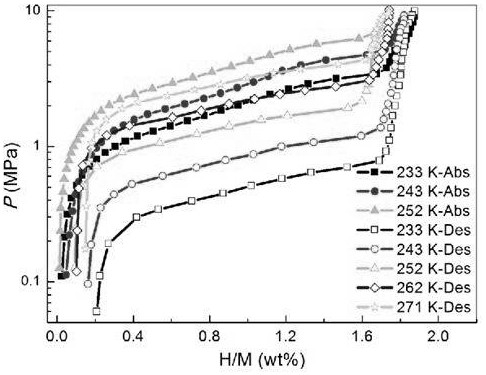

[0043] Embodiment 1: melting alloy Ti 1.1 Cr 0.95 Fe 0.05 mn 1.0 Alloy, and test its PCT curve.

[0044] (1) Take the raw materials, Ti: 2.641g, Cr: 2.474g, Fe: 0.144g, Mn: 2.959g, among which Mn is excessive, put the prepared materials in the electric arc furnace, turn on the vacuum system to reduce the vacuum of the system to 10 -3 Under Pa, feed high-purity argon to a pressure of 0.9atm, energize and start arc melting, smelting for 1.5min, smelting once and turning over after condensation, and smelting again for 1.5min, a total of three smelting times.

[0045] (2) Take out the alloy after smelting and weigh its mass, which basically guarantees that the mass of the alloy at this time is greater than or close to the mass of the target alloy, and the weight of the alloy at this time is 8.002g.

[0046] (3) Put the final smelted alloy into the heat treatment furnace, and turn on the vacuum system to evacuate to 3.5 10 -3 Pa, 0.7atm high-purity Ar gas (99.99%) was intr...

Embodiment 2

[0048] Embodiment 2: melting alloy Ti 1.1 Cr 0.9 Fe 0.1 mn 1.0 Alloy, and test its PCT curve.

[0049] (1) Take the raw materials, Ti: 2.639g, Cr: 2.342g, Fe: 0.279 g, Mn: 2.946 g, among which Mn is excessive, put the prepared materials in the electric arc furnace, open the vacuum system to reduce the vacuum of the system to 10 -3 Under Pa, feed high-purity argon to a pressure of 0.9atm, energize and start arc melting, smelting for 1.5min, smelting once and turning over after condensation, and smelting again for 1.5min, a total of three smelting times.

[0050] (2) Take out the alloy after smelting and weigh its mass, which basically guarantees that the mass of the alloy at this time is greater than or close to the mass of the target alloy, and the weight of the alloy at this time is 7.987g.

[0051] (3) Put the final smelted alloy into the heat treatment furnace, and turn on the vacuum system to evacuate to 3.5 10 -3 Pa, 0.7atm high-purity Ar gas (99.99%) was introdu...

Embodiment 3

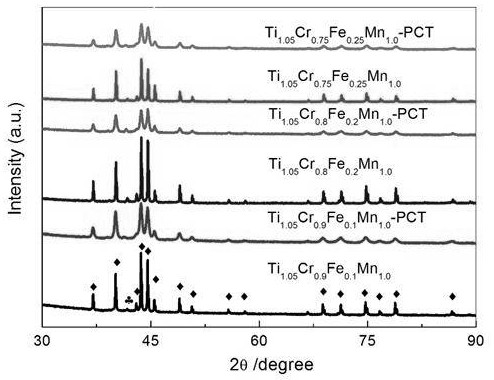

[0053] Embodiment 3: melting alloy Ti 1.05 Cr 0.9 Fe 0.1 mn 1.0 Alloy, and test its PCT curve.

[0054] (1) Take the raw materials, Ti: 2.556g, Cr: 2.379g, Fe: 0.284 g, Mn: 2.957 g, of which Mn is excessive, put the prepared materials in the electric arc furnace, turn on the vacuum system to reduce the vacuum of the system to 10 -3 Under Pa, feed high-purity argon to a pressure of 0.9atm, energize and start arc melting, smelting for 1.5min, smelting once and turning over after condensation, and smelting again for 1.5min, a total of three smelting times.

[0055] (2) Take out the alloy after smelting and weigh its mass, which basically guarantees that the mass of the alloy at this time is greater than or close to the mass of the target alloy, and the weight of the alloy at this time is 7.994g.

[0056] (3) Put the final smelted alloy into the heat treatment furnace, and turn on the vacuum system to evacuate to 3.5 10 -3 Pa, 0.7atm high-purity Ar gas (99.99%) was introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com